MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Assembly<br />

Pinion Roller Bearing Pre-Load Adjustment<br />

The pre-load value of the pinion measured as<br />

per fig. 49 is the one indicated in the table below:<br />

MODELO<br />

120<br />

145/147<br />

155<br />

160<br />

185<br />

Method Using Press<br />

Note :<br />

If a press is not available, use the assembly<br />

method with the yoke (universal joint fork).<br />

A - Lubricate all the pinion roller bearings with<br />

the oil specified in the LUBRICATION section.<br />

B - Press the cone of the front roller bearing<br />

and rotate the pinion box several times to<br />

ensure a suitable seating between covers<br />

and cones. Maintain the pinion box under<br />

the press with an applied load.<br />

MODEL<br />

120<br />

145/147<br />

155/160/185<br />

USED ROLLER<br />

NEW ROLLER BEARINGS BEARINGS<br />

KG LB KG<br />

LB<br />

3,4 - 5,1<br />

0,7 - 6,7<br />

2,1 - 4,8<br />

0,5 - 5,1<br />

0,5 - 5,1<br />

7,7 - 11,8 2,0 - 3,1 4,6 - 6,9<br />

1,7 - 15,0 1,5 - 4,6 3,3 - 10,0<br />

4,5 - 10,6 1,3 - 2,8 3,0 - 6,0<br />

1,3 - 11,4 1,1 - 3,5 2,5 - 7,6<br />

1,3 - 11,4 1,1 - 3,5 2,5 - 7,6<br />

LOAD (TON)<br />

6 (MAX)<br />

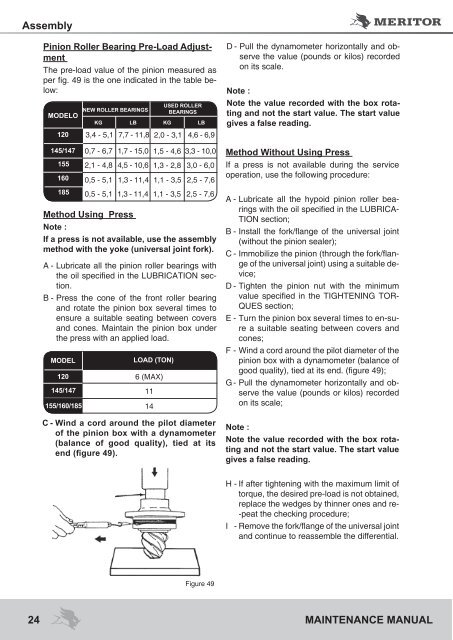

C - Wind a cord around the pilot diameter<br />

of the pinion box with a dynamometer<br />

(balance of good quality), tied at its<br />

end (figure 49).<br />

11<br />

14<br />

D - Pull the dynamometer horizontally and observe<br />

the value (pounds or kilos) recorded<br />

on its scale.<br />

Note :<br />

Note the value recorded with the box rotating<br />

and not the start value. The start value<br />

gives a false reading.<br />

Method Without Using Press<br />

If a press is not available during the service<br />

operation, use the following procedure:<br />

A - Lubricate all the hypoid pinion roller bearings<br />

with the oil specified in the LUBRICA-<br />

TION section;<br />

B - Install the fork/flange of the universal joint<br />

(without the pinion sealer);<br />

C - Immobilize the pinion (through the fork/flange<br />

of the universal joint) using a suitable device;<br />

D - Tighten the pinion nut with the minimum<br />

value specified in the TIGHTENING TOR-<br />

QUES section;<br />

E - Turn the pinion box several times to en-sure<br />

a suitable seating between covers and<br />

cones;<br />

F - Wind a cord around the pilot diameter of the<br />

pinion box with a dynamometer (balance of<br />

good quality), tied at its end. (figure 49);<br />

G - Pull the dynamometer horizontally and observe<br />

the value (pounds or kilos) recorded<br />

on its scale;<br />

Note :<br />

Note the value recorded with the box rotating<br />

and not the start value. The start value<br />

gives a false reading.<br />

H - If after tightening with the maximum limit of<br />

torque, the desired pre-load is not obtained,<br />

replace the wedges by thinner ones and re-<br />

-peat the checking procedure;<br />

I - Remove the fork/flange of the universal joint<br />

and continue to reassemble the differential.<br />

Figure 49<br />

24 <strong>MAINTENANCE</strong> <strong>MANUAL</strong>