High Speed Harmonic Drive Gearing - Electromate Industrial Sales ...

High Speed Harmonic Drive Gearing - Electromate Industrial Sales ...

High Speed Harmonic Drive Gearing - Electromate Industrial Sales ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>High</strong> <strong>Speed</strong> <strong>Harmonic</strong><br />

<strong>Drive</strong> <strong>Gearing</strong><br />

Automation equipment is constantly seeking<br />

increased throughput-it's a never ending requirement.<br />

For power transmission components, this translates<br />

into either higher motor speeds or lower gear ratios.<br />

Most applications desire lower gear ratios since life,<br />

wear, and noise generally increase with higher speed<br />

option.<br />

<strong>Harmonic</strong> drive gearing is a popular choice for many<br />

automation applications because of its superior power<br />

transmission qualities, which include zero backlash, high torsional stiffness,high<br />

positional accuracy, and torque-to-weight ratios. Until recently, however, the lowest gear<br />

ratio available has been 50:1. New proprietary tooth design technology has substantially<br />

reduced this old limit, making ratios of 30:1 possible.<br />

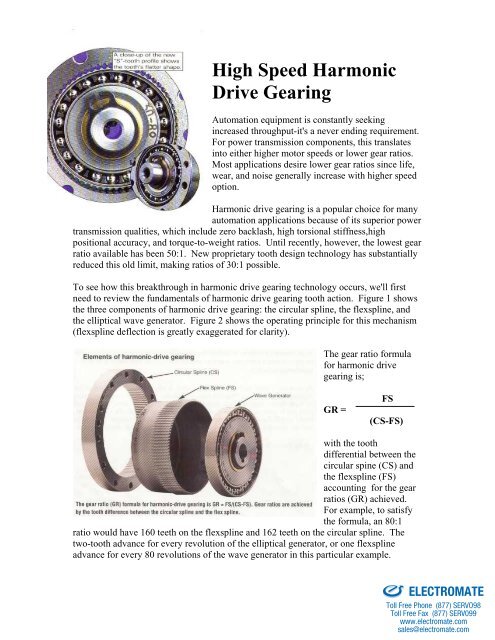

To see how this breakthrough in harmonic drive gearing technology occurs, we'll first<br />

need to review the fundamentals of harmonic drive gearing tooth action. Figure 1 shows<br />

the three components of harmonic drive gearing: the circular spline, the flexspline, and<br />

the elliptical wave generator. Figure 2 shows the operating principle for this mechanism<br />

(flexspline deflection is greatly exaggerated for clarity).<br />

The gear ratio formula<br />

for harmonic drive<br />

gearing is;<br />

GR =<br />

FS<br />

(CS-FS)<br />

with the tooth<br />

differential between the<br />

circular spine (CS) and<br />

the flexspline (FS)<br />

accounting for the gear<br />

ratios (GR) achieved.<br />

For example, to satisfy<br />

the formula, an 80:1<br />

ratio would have 160 teeth on the flexspline and 162 teeth on the circular spline. The<br />

two-tooth advance for every revolution of the elliptical generator, or one flexspline<br />

advance for every 80 revolutions of the wave generator in this particular example.<br />

Sold & Serviced By:<br />

ELECTROMATE<br />

Toll Free Phone (877) SERVO98<br />

Toll Free Fax (877) SERV099<br />

www.electromate.com<br />

sales@electromate.com

<strong>Harmonic</strong> drive gears operate by engaging multiple teeth at the major axes while<br />

disengaging them at the minor axes of the wave generator ellipse. To minimize flex<br />

stress in the flexspline, our goal is to keep ellipicity to a minimum, which leads us to<br />

small tooth height. Achieving a 50:1 ratio, for example, means producing a 100-tooth<br />

circular spline. As the number of teeth decreases, their size increases; consequently,<br />

ellipicity must increase to provide the required clearance at the minor axis. In older<br />

designs, ratios below 80:1 more often than not made use of a four-tooth difference,<br />

usually doubling the number of teeth to 200 for a 50:1 ratio in order to reduce the tooth<br />

size. Achieving a ratio of approximately 30:1 meant changes in the tooth design were<br />

required.<br />

HD Systems introduced the "S"-tooth design in 1991. This profile, a departure<br />

from the old involute-tooth form, brought many advantages to harmonic drive gearing,<br />

such as increased torque capacity, stronger teeth, longer life, and higher torsional<br />

stiffness. Figure 3 shows the "S"-tooth profile and the relative motions of the flexspline<br />

and circular spline in operation. Developing the new tooth form required significant<br />

design analysis, resulting in a profile that lets high numbers of teeth in simultaneous<br />

contact share in carrying the load while keeping a low ellipticity. This "S"-tooth profile<br />

brought another benefit to harmonic drive gearing by permitting a reduction in ratio down<br />

to 50:1, using the two-tooth difference.<br />

Nonetheless, getting 30:1 ratios with a two-tooth difference required further<br />

profile modifications. In the past, the axisymmetric nature of harmonic drive gearing<br />

permitted the use of two-dimensional modeling, which was sufficient to study the<br />

kinematics and stress distribution for ratios of 50:1 and higher. However, the demands of<br />

30:1 ratios required a degree of modeling sophistication that two-dimensional models<br />

could not deliver. We developed a complex three-dimensional simulation of tooth<br />

engagement so that parameters of the "S"-tooth profile could be studied, examined, and<br />

modified for optimum engagement and minimum wear. This procedure included detailed<br />

finite element analysis of the flexspline toothbed, identifying high stress areas and<br />

allowing design modifications for reducing stress to safe and reliable limits.<br />

Sold & Serviced By:<br />

ELECTROMATE<br />

Toll Free Phone (877) SERVO98<br />

Toll Free Fax (877) SERV099<br />

www.electromate.com<br />

sales@electromate.com

Figure 4 shows the new "S"-tooth (for 30:1) action in the circular-spline/flexspline<br />

interface.<br />

The result is a new profile that permits 30:1 gear ratios using the two-tooth<br />

difference, minimizing ellipticity and maintaining low flexspline stresses. In addition,<br />

this new "S"-tooth profile still provides all of the benefits of "S"-tooth harmonic drive<br />

gearing. This technology can be incorporated into the complete into the complete range<br />

of products, including component sets, gearheads, and servo actuators. With the new<br />

lower ratios available, harmonic drive gearing may now be used in applications where<br />

planetary or other low-ratio gears might have been used previously, thus allowing a<br />

reduction in package size and weight while increasing positional accuracy and achieving<br />

zero backlash. This new tooth profile is a major step forward in expanding the range of<br />

applications suitable for harmonic drive gearing and in addressing industry's need for<br />

increased throughput and accuracy.<br />

Sold & Serviced By:<br />

ELECTROMATE<br />

Toll Free Phone (877) SERVO98<br />

Toll Free Fax (877) SERV099<br />

www.electromate.com<br />

sales@electromate.com