Section 17 Strength and Durability of Gears - SDP/SI

Section 17 Strength and Durability of Gears - SDP/SI

Section 17 Strength and Durability of Gears - SDP/SI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ELEMENTS OF METRIC GEAR TECHNOLOGY<br />

b<br />

–––<br />

d 1<br />

0.2<br />

0.4<br />

0.6<br />

0.8<br />

1.0<br />

1.2<br />

1.4<br />

1.6<br />

1.8<br />

2.0<br />

PHONE: 516.328.3300 • FAX: 516.326.8827 • WWW.<strong>SDP</strong>-<strong>SI</strong>.COM<br />

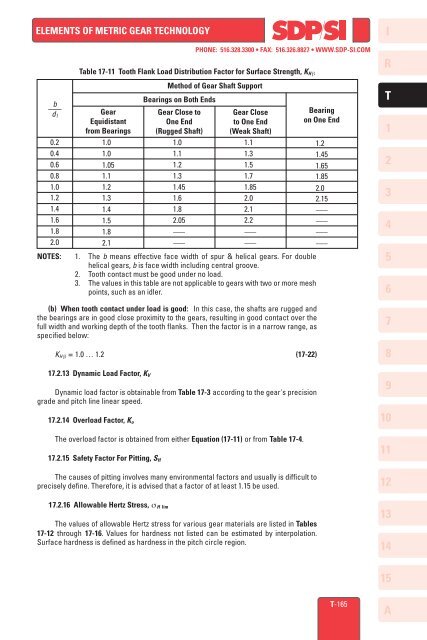

Table <strong>17</strong>-11 Tooth Flank Load Distribution Factor for Surface <strong>Strength</strong>, K H β<br />

Gear<br />

Equidistant<br />

from Bearings<br />

1.0<br />

1.0<br />

1.05<br />

1.1<br />

1.2<br />

1.3<br />

1.4<br />

1.5<br />

1.8<br />

2.1<br />

Method <strong>of</strong> Gear Shaft Support<br />

Bearings on Both Ends<br />

Gear Close to<br />

One End<br />

(Rugged Shaft)<br />

1.0<br />

1.1<br />

1.2<br />

1.3<br />

1.45<br />

1.6<br />

1.8<br />

2.05<br />

–––<br />

–––<br />

Gear Close<br />

to One End<br />

(Weak Shaft)<br />

1.1<br />

1.3<br />

1.5<br />

1.7<br />

1.85<br />

2.0<br />

2.1<br />

2.2<br />

–––<br />

–––<br />

NOTES: 1. The b means effective face width <strong>of</strong> spur & helical gears. For double<br />

helical gears, b is face width including central groove.<br />

2. Tooth contact must be good under no load.<br />

3. The values in this table are not applicable to gears with two or more mesh<br />

points, such as an idler.<br />

(b) When tooth contact under load is good: In this case, the shafts are rugged <strong>and</strong><br />

the bearings are in good close proximity to the gears, resulting in good contact over the<br />

full width <strong>and</strong> working depth <strong>of</strong> the tooth flanks. Then the factor is in a narrow range, as<br />

specified below:<br />

K H β = 1.0 … 1.2 (<strong>17</strong>-22)<br />

<strong>17</strong>.2.13 Dynamic Load Factor, K V<br />

Dynamic load factor is obtainable from Table <strong>17</strong>-3 according to the gear's precision<br />

grade <strong>and</strong> pitch line linear speed.<br />

<strong>17</strong>.2.14 Overload Factor, K o<br />

The overload factor is obtained from either Equation (<strong>17</strong>-11) or from Table <strong>17</strong>-4.<br />

<strong>17</strong>.2.15 Safety Factor For Pitting, S H<br />

The causes <strong>of</strong> pitting involves many environmental factors <strong>and</strong> usually is difficult to<br />

precisely define. Therefore, it is advised that a factor <strong>of</strong> at least 1.15 be used.<br />

Bearing<br />

on One End<br />

1.2<br />

1.45<br />

1.65<br />

1.85<br />

2.0<br />

2.15<br />

–––<br />

–––<br />

–––<br />

–––<br />

I<br />

R<br />

T<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

<strong>17</strong>.2.16 Allowable Hertz Stress, σ H lim<br />

The values <strong>of</strong> allowable Hertz stress for various gear materials are listed in Tables<br />

<strong>17</strong>-12 through <strong>17</strong>-16. Values for hardness not listed can be estimated by interpolation.<br />

Surface hardness is defined as hardness in the pitch circle region.<br />

13<br />

14<br />

15<br />

T-165<br />

A