Section 17 Strength and Durability of Gears - SDP/SI

Section 17 Strength and Durability of Gears - SDP/SI

Section 17 Strength and Durability of Gears - SDP/SI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

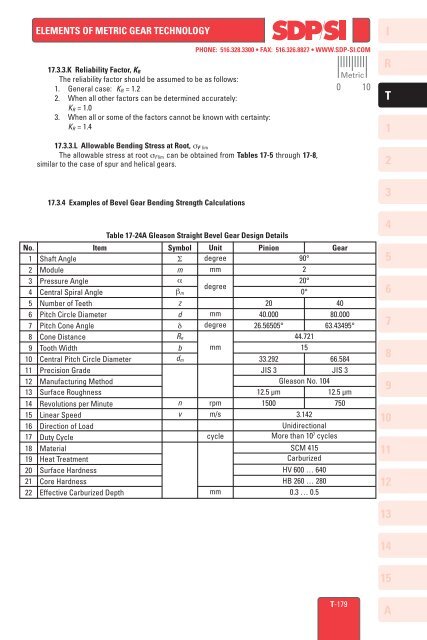

ELEMENTS OF METRIC GEAR TECHNOLOGY<br />

<strong>17</strong>.3.3.K Reliability Factor, K R<br />

The reliability factor should be assumed to be as follows:<br />

1. General case: K R = 1.2<br />

2. When all other factors can be determined accurately:<br />

K R = 1.0<br />

3. When all or some <strong>of</strong> the factors cannot be known with certainty:<br />

K R = 1.4<br />

PHONE: 516.328.3300 • FAX: 516.326.8827 • WWW.<strong>SDP</strong>-<strong>SI</strong>.COM<br />

<strong>17</strong>.3.3.L Allowable Bending Stress at Root, σ F lim<br />

The allowable stress at root σ F lim can be obtained from Tables <strong>17</strong>-5 through <strong>17</strong>-8,<br />

similar to the case <strong>of</strong> spur <strong>and</strong> helical gears.<br />

<strong>17</strong>.3.4 Examples <strong>of</strong> Bevel Gear Bending <strong>Strength</strong> Calculations<br />

Table <strong>17</strong>-24A Gleason Straight Bevel Gear Design Details<br />

No. Item Symbol Unit Pinion Gear<br />

Σ<br />

m<br />

degree<br />

mm<br />

90°<br />

2<br />

α<br />

20°<br />

degree<br />

β m<br />

0°<br />

z<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

<strong>17</strong><br />

18<br />

19<br />

20<br />

21<br />

22<br />

Shaft Angle<br />

Module<br />

Pressure Angle<br />

Central Spiral Angle<br />

Number <strong>of</strong> Teeth<br />

Pitch Circle Diameter<br />

Pitch Cone Angle<br />

Cone Distance<br />

Tooth Width<br />

Central Pitch Circle Diameter<br />

Precision Grade<br />

Manufacturing Method<br />

Surface Roughness<br />

Revolutions per Minute<br />

Linear Speed<br />

Direction <strong>of</strong> Load<br />

Duty Cycle<br />

Material<br />

Heat Treatment<br />

Surface Hardness<br />

Core Hardness<br />

Effective Carburized Depth<br />

d<br />

δ<br />

Re<br />

b<br />

d m<br />

n<br />

v<br />

mm<br />

degree<br />

mm<br />

rpm<br />

m/s<br />

cycle<br />

mm<br />

20<br />

40<br />

40.000<br />

80.000<br />

26.56505°<br />

63.43495°<br />

44.721<br />

15<br />

33.292<br />

66.584<br />

JIS 3<br />

JIS 3<br />

Gleason No. 104<br />

12.5 µm<br />

1500<br />

3.142<br />

Unidirectional<br />

More than 10 7 cycles<br />

SCM 415<br />

Carburized<br />

HV 600 … 640<br />

HB 260 … 280<br />

0.3 … 0.5<br />

Metric<br />

0 10<br />

12.5 µm<br />

750<br />

I<br />

R<br />

T<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

T-<strong>17</strong>9<br />

A