Section 17 Strength and Durability of Gears - SDP/SI

Section 17 Strength and Durability of Gears - SDP/SI

Section 17 Strength and Durability of Gears - SDP/SI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

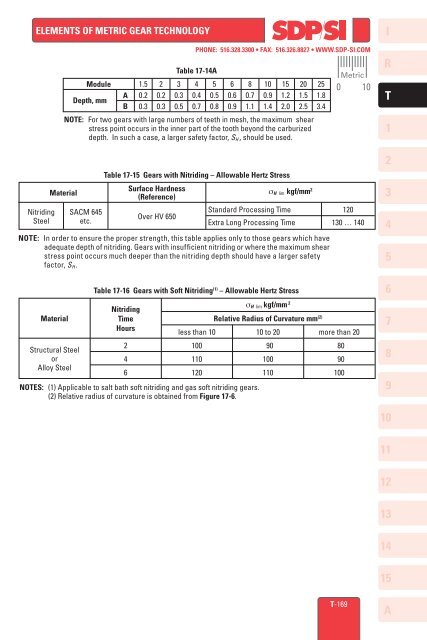

ELEMENTS OF METRIC GEAR TECHNOLOGY<br />

Nitriding<br />

Steel<br />

Module 1.5<br />

A 0.2<br />

Depth, mm<br />

B 0.3<br />

2<br />

0.2<br />

0.3<br />

PHONE: 516.328.3300 • FAX: 516.326.8827 • WWW.<strong>SDP</strong>-<strong>SI</strong>.COM<br />

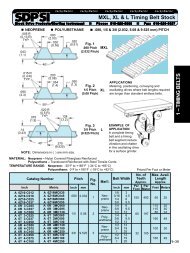

Table <strong>17</strong>-14A<br />

3<br />

0.3<br />

0.5<br />

4<br />

0.4<br />

0.7<br />

5<br />

0.5<br />

0.8<br />

6<br />

0.6<br />

0.9<br />

8<br />

0.7<br />

1.1<br />

10<br />

0.9<br />

1.4<br />

15<br />

1.2<br />

2.0<br />

NOTE: For two gears with large numbers <strong>of</strong> teeth in mesh, the maximum shear<br />

stress point occurs in the inner part <strong>of</strong> the tooth beyond the carburized<br />

depth. In such a case, a larger safety factor, S H , should be used.<br />

Table <strong>17</strong>-15 <strong>Gears</strong> with Nitriding – Allowable Hertz Stress<br />

Surface Hardness<br />

Material σ H lim kgf/mm 2<br />

(Reference)<br />

NOTE: In order to ensure the proper strength, this table applies only to those gears which have<br />

adequate depth <strong>of</strong> nitriding. <strong>Gears</strong> with insufficient nitriding or where the maximum shear<br />

stress point occurs much deeper than the nitriding depth should have a larger safety<br />

factor, S H .<br />

Material<br />

Structural Steel<br />

or<br />

Alloy Steel<br />

SACM 645<br />

etc.<br />

Over HV 650<br />

St<strong>and</strong>ard Processing Time<br />

Extra Long Processing Time<br />

Table <strong>17</strong>-16 <strong>Gears</strong> with S<strong>of</strong>t Nitriding (1) – Allowable Hertz Stress<br />

Nitriding<br />

Time<br />

Hours<br />

2<br />

4<br />

6<br />

less than 10<br />

NOTES: (1) Applicable to salt bath s<strong>of</strong>t nitriding <strong>and</strong> gas s<strong>of</strong>t nitriding gears.<br />

(2) Relative radius <strong>of</strong> curvature is obtained from Figure <strong>17</strong>-6.<br />

100<br />

110<br />

120<br />

σ H lim kgf/mm 2<br />

20<br />

1.5<br />

2.5<br />

25<br />

1.8<br />

3.4<br />

Relative Radius <strong>of</strong> Curvature mm (2)<br />

10 to 20<br />

90<br />

100<br />

110<br />

Metric<br />

0 10<br />

120<br />

130 … 140<br />

more than 20<br />

80<br />

90<br />

100<br />

I<br />

R<br />

T<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

T-169<br />

A