Section 17 Strength and Durability of Gears - SDP/SI

Section 17 Strength and Durability of Gears - SDP/SI

Section 17 Strength and Durability of Gears - SDP/SI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

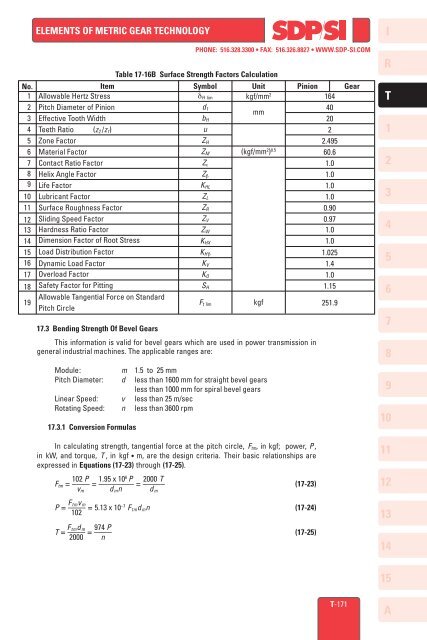

ELEMENTS OF METRIC GEAR TECHNOLOGY<br />

PHONE: 516.328.3300 • FAX: 516.326.8827 • WWW.<strong>SDP</strong>-<strong>SI</strong>.COM<br />

No. Item Symbol Unit Pinion Gear<br />

1 Allowable Hertz Stress<br />

kgf/mm 2<br />

164<br />

2 Pitch Diameter <strong>of</strong> Pinion<br />

40<br />

mm<br />

3 Effective Tooth Width<br />

20<br />

4 Teeth Ratio (z 2 /z 1 )<br />

2<br />

5 Zone Factor<br />

2.495<br />

6 Material Factor<br />

(kgf/mm 2 ) 0.5<br />

60.6<br />

7 Contact Ratio Factor<br />

1.0<br />

8 Helix Angle Factor<br />

1.0<br />

9 Life Factor<br />

1.0<br />

10 Lubricant Factor<br />

1.0<br />

11 Surface Roughness Factor<br />

0.90<br />

Sliding Speed Factor<br />

0.97<br />

Hardness Ratio Factor<br />

1.0<br />

Dimension Factor <strong>of</strong> Root Stress<br />

1.0<br />

12<br />

13<br />

14<br />

15<br />

16<br />

<strong>17</strong><br />

18<br />

19<br />

Load Distribution Factor<br />

Dynamic Load Factor<br />

Overload Factor<br />

Safety Factor for Pitting<br />

Allowable Tangential Force on St<strong>and</strong>ard<br />

Pitch Circle<br />

<strong>17</strong>.3 Bending <strong>Strength</strong> Of Bevel <strong>Gears</strong><br />

Table <strong>17</strong>-16B Surface <strong>Strength</strong> Factors Calculation<br />

δ H lim<br />

d 1<br />

b H<br />

u<br />

Z H<br />

Z M<br />

Z ε<br />

Z β<br />

K HL<br />

Z L<br />

Z R<br />

Z V<br />

Z W<br />

K HX<br />

K H β<br />

K V<br />

K O<br />

S H<br />

This information is valid for bevel gears which are used in power transmission in<br />

general industrial machines. The applicable ranges are:<br />

F t lim<br />

Module:<br />

m 1.5 to 25 mm<br />

Pitch Diameter: d less than 1600 mm for straight bevel gears<br />

less than 1000 mm for spiral bevel gears<br />

Linear Speed: v less than 25 m/sec<br />

Rotating Speed: n less than 3600 rpm<br />

<strong>17</strong>.3.1 Conversion Formulas<br />

In calculating strength, tangential force at the pitch circle, F tm , in kgf; power, P ,<br />

in kW, <strong>and</strong> torque, T , in kgf • m, are the design criteria. Their basic relationships are<br />

expressed in Equations (<strong>17</strong>-23) through (<strong>17</strong>-25).<br />

102 P 1.95 x 10 6 P 2000 T<br />

F tm = –––– = –––––––– = ––––– (<strong>17</strong>-23)<br />

v m d m n d m<br />

F tm v m<br />

P = –––– = 5.13 x 10 –7 F tm d m n (<strong>17</strong>-24)<br />

102<br />

F tm d m 974 P<br />

T = –––– = –––– (<strong>17</strong>-25)<br />

2000 n<br />

kgf<br />

1.025<br />

1.4<br />

1.0<br />

1.15<br />

251.9<br />

I<br />

R<br />

T<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

T-<strong>17</strong>1<br />

A