Chemwatch Australian MSDS 31-8731 - FUJIFILM Australia

Chemwatch Australian MSDS 31-8731 - FUJIFILM Australia

Chemwatch Australian MSDS 31-8731 - FUJIFILM Australia

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>FUJIFILM</strong> CN-16Q NQ3-RS<br />

<strong>Chemwatch</strong> Independent Material Safety Data Sheet<br />

Issue Date: 7-May-2012 CHEMWATCH <strong>31</strong>-87<strong>31</strong><br />

X9<strong>31</strong>7SP(cs)<br />

Version No:2.0<br />

CD 2012/2 Page 1 of 8<br />

Section 1 - CHEMICAL PRODUCT AND COMPANY IDENTIFICATION<br />

PRODUCT NAME<br />

<strong>FUJIFILM</strong> CN-16Q NQ3-RS 850185<br />

PRODUCT CODE 391030<br />

PRODUCT USE<br />

■ Used according to manufacturer's directions.<br />

SUPPLIER<br />

Company: <strong>FUJIFILM</strong> <strong>Australia</strong> Pty Ltd<br />

Address:<br />

114 Old Pittwater Road<br />

Brookvale<br />

NSW, 2100<br />

<strong>Australia</strong><br />

Telephone: +61 2 9466 2600<br />

Emergency Tel: +61 1800 039 008<br />

Emergency Tel: +61 3 9573 <strong>31</strong>12<br />

Fax: +61 2 9938 1975<br />

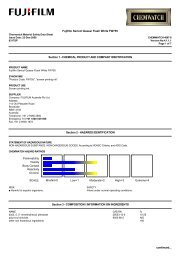

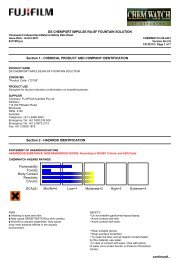

Section 2 - HAZARDS IDENTIFICATION<br />

STATEMENT OF HAZARDOUS NATURE<br />

HAZARDOUS SUBSTANCE. NON-DANGEROUS GOODS. According to the Criteria of NOHSC, and the ADG Code.<br />

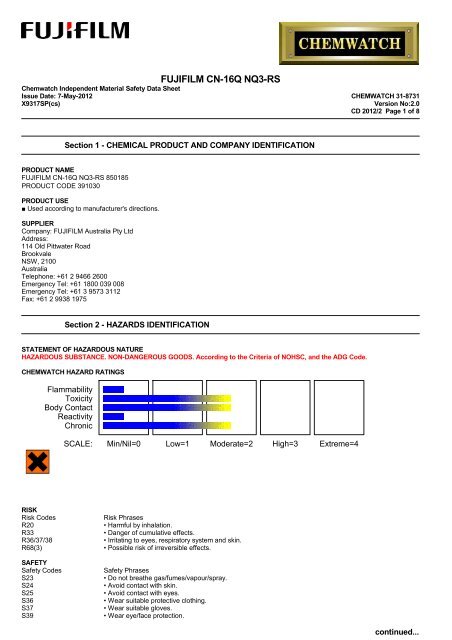

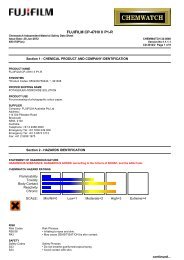

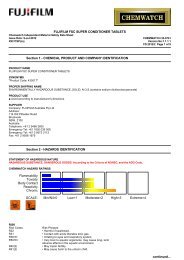

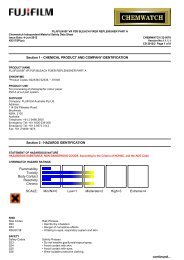

CHEMWATCH HAZARD RATINGS<br />

Flammability<br />

Toxicity<br />

Body Contact<br />

Reactivity<br />

Chronic<br />

SCALE: Min/Nil=0 Low=1 Moderate=2 High=3 Extreme=4<br />

RISK<br />

Risk Codes<br />

R20<br />

R33<br />

R36/37/38<br />

R68(3)<br />

SAFETY<br />

Safety Codes<br />

S23<br />

S24<br />

S25<br />

S36<br />

S37<br />

S39<br />

Risk Phrases<br />

• Harmful by inhalation.<br />

• Danger of cumulative effects.<br />

• Irritating to eyes, respiratory system and skin.<br />

• Possible risk of irreversible effects.<br />

Safety Phrases<br />

• Do not breathe gas/fumes/vapour/spray.<br />

• Avoid contact with skin.<br />

• Avoid contact with eyes.<br />

• Wear suitable protective clothing.<br />

• Wear suitable gloves.<br />

• Wear eye/face protection.<br />

continued...

<strong>FUJIFILM</strong> CN-16Q NQ3-RS<br />

<strong>Chemwatch</strong> Independent Material Safety Data Sheet<br />

Issue Date: 7-May-2012 CHEMWATCH <strong>31</strong>-87<strong>31</strong><br />

X9<strong>31</strong>7SP(cs)<br />

Version No:2.0<br />

CD 2012/2 Page 2 of 8<br />

Section 2 - HAZARDS IDENTIFICATION<br />

S51<br />

S09<br />

S40<br />

S07<br />

S13<br />

S26<br />

S46<br />

• Use only in well ventilated areas.<br />

• Keep container in a well ventilated place.<br />

• To clean the floor and all objects contaminated by this material, use water.<br />

• Keep container tightly closed.<br />

• Keep away from food, drink and animal feeding stuffs.<br />

• In case of contact with eyes, rinse with plenty of water and contact Doctor or<br />

Poisons Information Centre.<br />

• If swallowed, IMMEDIATELY contact Doctor or Poisons Information Centre. (show<br />

this container or label).<br />

Section 3 - COMPOSITION / INFORMATION ON INGREDIENTS<br />

NAME CAS RN %<br />

diammonium thiosulfate 7783-18-8 30-50<br />

sodium sulfite 7757-83-7 1-5<br />

EDTA disodium salt 139-33-3 0.1-1<br />

water 7732-18-5 40-60<br />

Section 4 - FIRST AID MEASURES<br />

SWALLOWED<br />

• If swallowed do NOT induce vomiting.<br />

• If vomiting occurs, lean patient forward or place on left side (head-down position, if possible) to maintain open airway and<br />

prevent aspiration.<br />

• Observe the patient carefully.<br />

• Never give liquid to a person showing signs of being sleepy or with reduced awareness; i.e. becoming unconscious.<br />

EYE<br />

■ If this product comes in contact with the eyes:<br />

• Wash out immediately with fresh running water.<br />

• Ensure complete irrigation of the eye by keeping eyelids apart and away from eye and moving the eyelids by occasionally lifting<br />

the upper and lower lids.<br />

• Seek medical attention without delay; if pain persists or recurs seek medical attention.<br />

• Removal of contact lenses after an eye injury should only be undertaken by skilled personnel.<br />

SKIN<br />

■ If skin or hair contact occurs:<br />

• Flush skin and hair with running water (and soap if available).<br />

• Seek medical attention in event of irritation.<br />

INHALED<br />

• If fumes or combustion products are inhaled remove from contaminated area.<br />

• Lay patient down. Keep warm and rested.<br />

• Prostheses such as false teeth, which may block airway, should be removed, where possible, prior to initiating first aid<br />

procedures.<br />

• Apply artificial respiration if not breathing, preferably with a demand valve resuscitator, bag-valve mask device, or pocket<br />

mask as trained. Perform CPR if necessary.<br />

• Inhalation of vapours or aerosols (mists, fumes) may cause lung oedema.<br />

• Corrosive substances may cause lung damage (e.g. lung oedema, fluid in the lungs).<br />

• As this reaction may be delayed up to 24 hours after exposure, affected individuals need complete rest (preferably in semirecumbent<br />

posture) and must be kept under medical observation even if no symptoms are (yet) manifested.<br />

• Before any such manifestation, the administration of a spray containing a dexamethasone derivative or beclomethasone derivative<br />

may be considered.<br />

NOTES TO PHYSICIAN<br />

■ Treat symptomatically.<br />

Depending on the degree of exposure, periodic medical examination is indicated. The symptoms of lung oedema often do not manifest<br />

until a few hours have passed and they are aggravated by physical effort.<br />

continued...

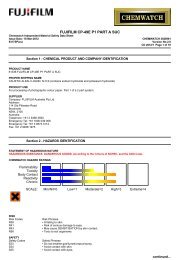

<strong>FUJIFILM</strong> CN-16Q NQ3-RS<br />

<strong>Chemwatch</strong> Independent Material Safety Data Sheet<br />

Issue Date: 7-May-2012 CHEMWATCH <strong>31</strong>-87<strong>31</strong><br />

X9<strong>31</strong>7SP(cs)<br />

Version No:2.0<br />

CD 2012/2 Page 3 of 8<br />

Section 5 - FIRE FIGHTING MEASURES<br />

EXTINGUISHING MEDIA<br />

• There is no restriction on the type of extinguisher which may be used.<br />

• Use extinguishing media suitable for surrounding area.<br />

FIRE FIGHTING<br />

• Alert Fire Brigade and tell them location and nature of hazard.<br />

• Wear breathing apparatus plus protective gloves in the event of a fire.<br />

• Prevent, by any means available, spillage from entering drains or water courses.<br />

• Use fire fighting procedures suitable for surrounding area.<br />

FIRE/EXPLOSION HAZARD<br />

• Non combustible.<br />

• Not considered a significant fire risk, however containers may burn.<br />

Decomposition may produce toxic fumes of: nitrogen oxides (NOx), sulfur oxides (SOx).<br />

May emit poisonous fumes.<br />

FIRE INCOMPATIBILITY<br />

■ None known.<br />

HAZCHEM<br />

None<br />

Section 6 - ACCIDENTAL RELEASE MEASURES<br />

MINOR SPILLS<br />

• Clean up all spills immediately.<br />

• Avoid breathing vapours and contact with skin and eyes.<br />

• Control personal contact with the substance, by using protective equipment.<br />

• Contain and absorb spill with sand, earth, inert material or vermiculite.<br />

MAJOR SPILLS<br />

■ Moderate hazard.<br />

• Clear area of personnel and move upwind.<br />

• Alert Fire Brigade and tell them location and nature of hazard.<br />

• Wear breathing apparatus plus protective gloves.<br />

• Prevent, by any means available, spillage from entering drains or water course.<br />

Personal Protective Equipment advice is contained in Section 8 of the <strong>MSDS</strong>.<br />

Section 7 - HANDLING AND STORAGE<br />

PROCEDURE FOR HANDLING<br />

• DO NOT allow clothing wet with material to stay in contact with skin.<br />

• Avoid all personal contact, including inhalation.<br />

• Wear protective clothing when risk of exposure occurs.<br />

• Use in a well-ventilated area.<br />

• Prevent concentration in hollows and sumps.<br />

SUITABLE CONTAINER<br />

• Polyethylene or polypropylene container.<br />

• Packing as recommended by manufacturer.<br />

• Check all containers are clearly labelled and free from leaks.<br />

STORAGE INCOMPATIBILITY<br />

■ For inorganic thiosulfates<br />

• Avoid storage with acids, metal nitrites, sodium nitrite, halogens and oxidizing agents.<br />

• Forms explosive product with potassium nitrate, sodium nitrate<br />

• Reacts with acids, forming sulfur dioxide<br />

• Incompatible with halogens, lead, silver and mercury salts. iodine.<br />

• Inorganic reducing agents react with oxidizing agents to generate heat and products that may be flammable, combustible, or<br />

otherwise reactive. Their reactions with oxidizing agents may be violent.<br />

• Incidents involving interaction of active oxidants and reducing agents, either by design or accident, are usually very<br />

continued...

<strong>FUJIFILM</strong> CN-16Q NQ3-RS<br />

<strong>Chemwatch</strong> Independent Material Safety Data Sheet<br />

Issue Date: 7-May-2012 CHEMWATCH <strong>31</strong>-87<strong>31</strong><br />

X9<strong>31</strong>7SP(cs)<br />

Version No:2.0<br />

CD 2012/2 Page 4 of 8<br />

Section 7 - HANDLING AND STORAGE<br />

energetic and examples of so-called redox reactions.<br />

Sulfites and hydrosulfites (dithionites) :<br />

• may react explosively with strong oxidising agents.<br />

• react with water or steam to produce corrosive acid solutions and sulfur oxide fumes - aqueous solutions are incompatible with<br />

oxidisers, strong acids, alkalis, ammonia, aliphatic amines, alkanolamines, alkylene oxides, amides, epichlorohydrin, organic<br />

anhydrides, isocyanates, nitromethane, vinyl acetate<br />

• aqueous solutions attack metals in presence of moisture<br />

• generate gaseous sulfur dioxide in contact with oxidising and nonoxidising acids.<br />

Sulfur dioxide:<br />

• reacts with water or steam forming sulfurous acid; reaction may be violent<br />

• reacts with acrolein, alcohols, aluminium powder, alkali metals, amines, bromine, pentafluoride, caustics, caesium, acetylene<br />

carbide, chlorates, chlorine trifluoride, chromium powder, copper or its alloy powders, diethylzinc, fluorine, lead dioxide,<br />

lithium acetylene carbide, metal powders, monolithium acetylide-ammonia, nitryl chloride, potassium acetylene carbide,<br />

potassium acetylide, potassium chlorate, rubidium carbide, silver azide, sodium, sodium acetylide, stannous oxide; reaction may<br />

be violent<br />

• decomposes above 60 deg. C releasing oxides of sulfur<br />

• Incompatible with alkalis, alkylene oxides, ammonia, aliphatic amines, alkanolamines, amides, organic anhydrides, caesium<br />

monoxide, epichlorohydrin, ferrous oxide, halogens, interhalogens, isocyanates, lithium nitrate, manganese, metal acetylides,<br />

metal oxides, perbromyl fluoride, red phosphorus, potassium azide, rubidium acetylide, sodium hydride, sulfuric acid.<br />

STORAGE REQUIREMENTS<br />

• Store in original containers.<br />

• Keep containers securely sealed.<br />

• Store in a cool, dry, well-ventilated area.<br />

• Store away from incompatible materials and foodstuff containers.<br />

Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTION<br />

EXPOSURE CONTROLS<br />

The following materials had no OELs on our records<br />

• diammonium thiosulfate: CAS:7783- 18- 8<br />

• sodium sulfite: CAS:7757- 83- 7 CAS:10102- 15- 5<br />

• EDTA disodium salt: CAS:139- 33- 3 CAS:69772- 70- 9<br />

• water: CAS:7732- 18- 5<br />

MATERIAL DATA<br />

DIAMMONIUM THIOSULFATE:<br />

EDTA DISODIUM SALT:<br />

■ It is the goal of the ACGIH (and other Agencies) to recommend TLVs (or their equivalent) for all substances for which there<br />

is evidence of health effects at airborne concentrations encountered in the workplace.<br />

At this time no TLV has been established, even though this material may produce adverse health effects (as evidenced in animal<br />

experiments or clinical experience).<br />

NOTE: The ACGIH occupational exposure standard for Particles Not Otherwise Specified (P.N.O.S) does NOT apply.<br />

<strong>FUJIFILM</strong> CN-16Q NQ3-RS:<br />

SODIUM SULFITE:<br />

■ Inorganic sulfites, bisulfites and metabisulfites (sodium, potassium and ammonium salts) liberate sulfur dioxide under<br />

certain conditions. Therefore the officially tabled exposure limits for these chemicals normally correspond to the yield of<br />

liberated sulfur dioxide.

<strong>FUJIFILM</strong> CN-16Q NQ3-RS<br />

<strong>Chemwatch</strong> Independent Material Safety Data Sheet<br />

Issue Date: 7-May-2012 CHEMWATCH <strong>31</strong>-87<strong>31</strong><br />

X9<strong>31</strong>7SP(cs)<br />

Version No:2.0<br />

CD 2012/2 Page 5 of 8<br />

Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTION<br />

RESPIRATOR<br />

•Particulate. (AS/NZS 1716 & 1715, EN 143:2000 & 149:2001, ANSI Z88 or national equivalent)<br />

EYE<br />

• Safety glasses with side shields<br />

• Chemical goggles.<br />

• Contact lenses may pose a special hazard; soft contact lenses may absorb and concentrate irritants. A written policy document,<br />

describing the wearing of lens or restrictions on use, should be created for each workplace or task. This should include a<br />

review of lens absorption and adsorption for the class of chemicals in use and an account of injury experience. Medical and<br />

first-aid personnel should be trained in their removal and suitable equipment should be readily available. In the event of<br />

chemical exposure, begin eye irrigation immediately and remove contact lens as soon as practicable. Lens should be removed at<br />

the first signs of eye redness or irritation - lens should be removed in a clean environment only after workers have washed<br />

hands thoroughly. [CDC NIOSH Current Intelligence Bulletin 59], [AS/NZS 1336 or national equivalent].<br />

HANDS/FEET<br />

• Wear chemical protective gloves, eg. PVC.<br />

• Wear safety footwear or safety gumboots, eg. Rubber.<br />

Suitability and durability of glove type is dependent on usage. Important factors in the selection of gloves include:<br />

• frequency and duration of contact,<br />

• chemical resistance of glove material,<br />

• glove thickness and<br />

• dexterity.<br />

OTHER<br />

• Overalls.<br />

• P.V.C. apron.<br />

• Barrier cream.<br />

• Skin cleansing cream.<br />

ENGINEERING CONTROLS<br />

■ Engineering controls are used to remove a hazard or place a barrier between the worker and the hazard. Well-designed<br />

engineering controls can be highly effective in protecting workers and will typically be independent of worker interactions to<br />

provide this high level of protection.<br />

The basic types of engineering controls are:<br />

Process controls which involve changing the way a job activity or process is done to reduce the risk.<br />

Enclosure and/or isolation of emission source which keeps a selected hazard "physically" away from the worker and ventilation<br />

that strategically "adds" and "removes" air in the work environment.<br />

Section 9 - PHYSICAL AND CHEMICAL PROPERTIES<br />

APPEARANCE<br />

Colourless liquid with a slight ammoniacal odour; mixes with water.<br />

PHYSICAL PROPERTIES<br />

Liquid.<br />

Mixes with water.<br />

State Liquid Molecular Weight Not Applicable<br />

Melting Range (°C) Not Available Viscosity Not Available<br />

Boiling Range (°C) Not Available Solubility in water (g/L) Miscible<br />

Flash Point (°C) Not Applicable pH (1% solution) Not Available<br />

Decomposition Temp (°C) Not Available pH (as supplied) 8.1<br />

Autoignition Temp (°C) Not Applicable Vapour Pressure (kPa) Not Available<br />

Upper Explosive Limit (%) Not Applicable Specific Gravity (water=1) 1.275<br />

Lower Explosive Limit (%) Not Applicable Relative Vapour Density Not Available<br />

(air=1)<br />

Volatile Component (%vol) Not Available Evaporation Rate Not Available<br />

continued...

<strong>FUJIFILM</strong> CN-16Q NQ3-RS<br />

<strong>Chemwatch</strong> Independent Material Safety Data Sheet<br />

Issue Date: 7-May-2012 CHEMWATCH <strong>31</strong>-87<strong>31</strong><br />

X9<strong>31</strong>7SP(cs)<br />

Version No:2.0<br />

CD 2012/2 Page 6 of 8<br />

Section 10 - STABILITY AND REACTIVITY<br />

CONDITIONS CONTRIBUTING TO INSTABILITY<br />

• Presence of incompatible materials.<br />

• Product is considered stable.<br />

• Hazardous polymerisation will not occur.<br />

For incompatible materials - refer to Section 7 - Handling and Storage.<br />

Section 11 - TOXICOLOGICAL INFORMATION<br />

POTENTIAL HEALTH EFFECTS<br />

ACUTE HEALTH EFFECTS<br />

SWALLOWED<br />

■ Accidental ingestion of the material may be damaging to the health of the individual.<br />

Thiosulfate salts are poorly absorbed and stimulate the emptying of thebowel.<br />

Large doses of ammonia or injected ammonium salts may produce diarrhoea and may be sufficiently absorbed to produce increased<br />

production of urine and systemic poisoning. Symptoms include weakening of facial muscle, tremor, anxiety, reduced muscle and limb<br />

control.<br />

EYE<br />

■ This material can cause eye irritation and damage in some persons.<br />

SKIN<br />

■ This material can cause inflammation of the skin oncontact in some persons.<br />

Entry into the blood-stream, through, for example, cuts, abrasions or lesions, may produce systemic injury with harmful effects.<br />

Examine the skin prior to the use of the material and ensure that any external damage is suitably protected.<br />

INHALED<br />

■ Inhalation of vapours or aerosols (mists, fumes), generated by the material during the course of normal handling, may be<br />

harmful.<br />

The material can cause respiratory irritation in some persons. The body's response to such irritation can cause further lung<br />

damage.<br />

CHRONIC HEALTH EFFECTS<br />

■ Substance accumulation, in the human body, is likely and may cause some concern following repeated or long-term occupational<br />

exposure.<br />

Strong evidence exists that this substance may cause irreversible mutations (though not lethal) even following a single exposure.<br />

Laboratory (in vitro) and animal studies show, exposure to the material may result in a possible risk of irreversible effects,<br />

with the possibility of producing mutation.<br />

Sulfites and bisulfites can cause narrowing of the airways, stomach upset, flushing, low blood pressure, tingling sensation,<br />

itchy wheal, swelling and shock, and asthmatics are especially prone. They induce allergic-like reactions which can occur on<br />

first contact with the material.<br />

TOXICITY AND IRRITATION<br />

■ No significant acute toxicological data identified in literature search.<br />

Contact allergies quickly manifest themselves as contact eczema, more rarely as urticaria or Quincke's oedema. The pathogenesis<br />

of contact eczema involves a cell-mediated (T lymphocytes) immune reaction of the delayed type. Other allergic skin reactions,<br />

e.g. contact urticaria, involve antibody-mediated immune reactions. The significance of the contact allergen is not simply<br />

determined by its sensitisation potential: the distribution of the substance and the opportunities for contact with it are<br />

equally important. A weakly sensitising substance which is widely distributed can be a more important allergen than one with<br />

stronger sensitising potential with which few individuals come into contact. From a clinical point of view, substances are<br />

noteworthy if they produce an allergic test reaction in more than 1% of the persons tested.<br />

Asthma-like symptoms may continue for months or even years after exposure to the material ceases. This may be due to a nonallergenic<br />

condition known as reactive airways dysfunction syndrome (RADS) which can occur following exposure to high levels of<br />

highly irritating compound.<br />

CARCINOGEN<br />

Sulfites International Agency for Research on Cancer Group 3<br />

(IARC) - Agents Reviewed by the IARC<br />

Monographs<br />

continued...

<strong>FUJIFILM</strong> CN-16Q NQ3-RS<br />

<strong>Chemwatch</strong> Independent Material Safety Data Sheet<br />

Issue Date: 7-May-2012 CHEMWATCH <strong>31</strong>-87<strong>31</strong><br />

X9<strong>31</strong>7SP(cs)<br />

Version No:2.0<br />

CD 2012/2 Page 7 of 8<br />

No data<br />

Section 12 - ECOLOGICAL INFORMATION<br />

Ecotoxicity<br />

Ingredient Persistence: Persistence: Air Bioaccumulation Mobility<br />

Water/Soil<br />

diammonium thiosulfate No Data No Data LOW<br />

Available<br />

Available<br />

sodium sulfite No Data No Data<br />

Available<br />

Available<br />

EDTA disodium salt LOW No Data LOW MED<br />

Available<br />

Section 13 - DISPOSAL CONSIDERATIONS<br />

• Containers may still present a chemical hazard/ danger when empty.<br />

• Return to supplier for reuse/ recycling if possible.<br />

Otherwise:<br />

• If container can not be cleaned sufficiently well to ensure that residuals do not remain or if the container cannot be used to<br />

store the same product, then puncture containers, to prevent re-use, and bury at an authorised landfill.<br />

• Where possible retain label warnings and <strong>MSDS</strong> and observe all notices pertaining to the product.<br />

Legislation addressing waste disposal requirements may differ by country, state and/ or territory. Each user must refer to laws<br />

operating in their area.<br />

A Hierarchy of Controls seems to be common - the user should investigate:<br />

• Reduction.<br />

• DO NOT allow wash water from cleaning or process equipment to enter drains.<br />

• It may be necessary to collect all wash water for treatment before disposal.<br />

• In all cases disposal to sewer may be subject to local laws and regulations and these should be considered first.<br />

• Where in doubt contact the responsible authority.<br />

• Recycle wherever possible.<br />

• Consult manufacturer for recycling options or consult local or regional waste management authority for disposal if no suitable<br />

treatment or disposal facility can be identified.<br />

• Dispose of by: burial in a land-fill specifically licenced to accept chemical and / or pharmaceutical wastes or incineration in<br />

a licenced apparatus (after admixture with suitable combustible material).<br />

• Decontaminate empty containers. Observe all label safeguards until containers are cleaned and destroyed.<br />

Section 14 - TRANSPORTATION INFORMATION<br />

HAZCHEM:<br />

None (ADG7)<br />

■ Air transport may be forbidden if this material is flammable, corrosive or toxic gases may be released under normal conditions<br />

of transport.<br />

NOT REGULATED FOR TRANSPORT OF DANGEROUS GOODS: ADG7, UN, IATA, IMDG<br />

Section 15 - REGULATORY INFORMATION<br />

POISONS SCHEDULE None<br />

REGULATIONS<br />

Fujifilm CN-16Q NQ3-Rs (CAS: ) is found on the following regulatory lists;<br />

"International Agency for Research on Cancer (IARC) - Agents Reviewed by the IARC Monographs"<br />

Regulations for ingredients<br />

diammonium thiosulfate (CAS: 7783-18-8) is found on the following regulatory lists;<br />

"<strong>Australia</strong> Hazardous Substances","<strong>Australia</strong> Inventory of Chemical Substances (AICS)","<strong>Australia</strong> National Pollutant Inventory",<br />

"OECD List of High Production Volume (HPV) Chemicals"<br />

Witco BWT 2010 (CAS: 7757-83-7,10102-15-5) is found on the following regulatory lists;<br />

"<strong>Australia</strong> - Victoria Drugs, Poisons and Controlled Substances (Precursor Chemicals) Regs 2007 - Schedule 1 - Precursor Chemicals<br />

continued...

<strong>FUJIFILM</strong> CN-16Q NQ3-RS<br />

<strong>Chemwatch</strong> Independent Material Safety Data Sheet<br />

Issue Date: 7-May-2012 CHEMWATCH <strong>31</strong>-87<strong>31</strong><br />

X9<strong>31</strong>7SP(cs)<br />

Version No:2.0<br />

CD 2012/2 Page 8 of 8<br />

Section 15 - REGULATORY INFORMATION<br />

and Quantities","<strong>Australia</strong> Inventory of Chemical Substances (AICS)","<strong>Australia</strong> National Pollutant Inventory","<strong>Australia</strong> Standard<br />

for the Uniform Scheduling of Medicines and Poisons (SUSMP) - Appendix F (Part 3)","International Agency for Research on Cancer<br />

(IARC) - Agents Reviewed by the IARC Monographs","OECD List of High Production Volume (HPV) Chemicals"<br />

EDTA disodium salt (CAS: 139-33-3,69772-70-9) is found on the following regulatory lists;<br />

"<strong>Australia</strong> Inventory of Chemical Substances (AICS)","OECD List of High Production Volume (HPV) Chemicals"<br />

water (CAS: 7732-18-5) is found on the following regulatory lists;<br />

"<strong>Australia</strong> Inventory of Chemical Substances (AICS)","International Fragrance Association (IFRA) Survey: Transparency List","OECD<br />

List of High Production Volume (HPV) Chemicals","OSPAR National List of Candidates for Substitution – Norway"<br />

Section 16 - OTHER INFORMATION<br />

Denmark Advisory list for selfclassification of dangerous substances<br />

Substance CAS Suggested codes<br />

EDTA disodium salt 139- 33- 3 Xn; R22<br />

INGREDIENTS WITH MULTIPLE CAS NUMBERS<br />

Ingredient Name<br />

CAS<br />

sodium sulfite 7757- 83- 7, 10102- 15- 5<br />

EDTA disodium salt 139- 33- 3, 69772- 70- 9<br />

■ Classification of the preparation and its individual components has drawn on official and authoritative sources as well as<br />

independent review by the <strong>Chemwatch</strong> Classification committee using available literature references.<br />

A list of reference resources used to assist the committee may be found at:<br />

www.chemwatch.net/references.<br />

■ The (M)SDS is a Hazard Communication tool and should be used to assist in the Risk Assessment. Many factors determine whether<br />

the reported Hazards are Risks in the workplace or other settings.<br />

This document is copyright. Apart from any fair dealing for the purposes of private study, research, review or<br />

criticism, as permitted under the Copyright Act, no part may be reproduced by any process without written<br />

permission from CHEMWATCH. TEL (+61 3) 9572 4700.<br />

Issue Date: 7-May-2012<br />

Print Date: 7-May-2012<br />

This is the end of the <strong>MSDS</strong>.