dtc 1491 (vacuum cut valve bypass valve) diagnosis - Lyberty

dtc 1491 (vacuum cut valve bypass valve) diagnosis - Lyberty

dtc 1491 (vacuum cut valve bypass valve) diagnosis - Lyberty

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Classification: Reference: Date<br />

EC02-008 NTB02-033 March 21, 2002<br />

DTC <strong>1491</strong> (VACUUM CUT VALVE BYPASS VALVE) DIAGNOSIS<br />

APPLIED VEHICLE(S):<br />

1998 – 2002 All Models<br />

SERVICE INFORMATION<br />

This bulletin is an aid to the diagnostic procedures in the Service Manual for DTC P<strong>1491</strong>.<br />

If one of the applied vehicles has the MIL “ON” with DTC P<strong>1491</strong> (Vacuum Cut Valve<br />

Bypass Valve) stored in Self-Diagnostic Results, use the service procedure in this bulletin<br />

and the appropriate Service Manual to help you <strong>diagnosis</strong> the incident, if it should occur.<br />

SERVICE PROCEDURE<br />

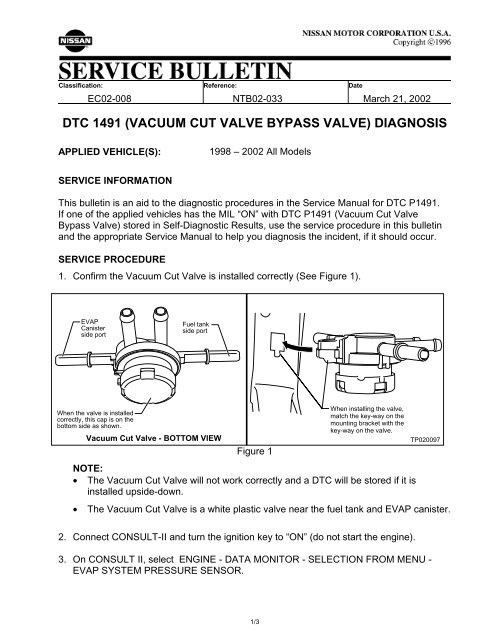

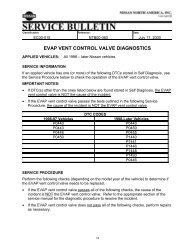

1. Confirm the Vacuum Cut Valve is installed correctly (See Figure 1).<br />

EVAP<br />

Canister<br />

side port<br />

Fuel tank<br />

side port<br />

When the <strong>valve</strong> is installed<br />

correctly, this cap is on the<br />

bottom side as shown.<br />

Vacuum Cut Valve - BOTTOM VIEW<br />

Figure 1<br />

When installing the <strong>valve</strong>,<br />

match the key-way on the<br />

mounting bracket with the<br />

key-way on the <strong>valve</strong>.<br />

NOTE:<br />

• The Vacuum Cut Valve will not work correctly and a DTC will be stored if it is<br />

installed upside-down.<br />

TP020097<br />

• The Vacuum Cut Valve is a white plastic <strong>valve</strong> near the fuel tank and EVAP canister.<br />

2. Connect CONSULT-II and turn the ignition key to “ON” (do not start the engine).<br />

3. On CONSULT II, select ENGINE - DATA MONITOR - SELECTION FROM MENU -<br />

EVAP SYSTEM PRESSURE SENSOR.<br />

1/3

4. Note the EVAP System Pressure Sensor Voltage. Confirm that it is reading in a normal<br />

range for a key ON and engine OFF condition.<br />

NOTE:<br />

For 2001 models and earlier:<br />

• Voltage in step 4 should be near 3.36 volts.<br />

• The normal range is between 3.32 - 3.40 volts.<br />

For 2002 models:<br />

• Some 2002 models use a new type EVAP System Pressure Sensor with different<br />

operational characteristics.<br />

• Refer to the EC section of the appropriate Service Manual to determine which<br />

type sensor your vehicle is equipped with.<br />

• Models that use the new type EVAP System Pressure Sensor will have a voltage<br />

reading that varies with changes in the “barometric” pressure (atmospheric air<br />

pressure that changes with altitude and/or weather conditions).<br />

• The usual voltage range obtained in step 4 with the new type EVAP System<br />

Pressure Sensor is between 3.8 and 4.2 volts. Because this range will vary with<br />

barometric pressure, it is best to compare readings with a known good vehicle.<br />

• Some 2002 models use the earlier type EVAP System Pressure Sensor (same<br />

as used on 2001 and earlier models). The normal range for the earlier type is<br />

3.32 to 3.40 volts and does not vary with barometric pressure.<br />

5. Start the engine. Observe the EVAP System Pressure Sensor voltage.<br />

• If the value has reduced 0.04 volts or more from the reading obtained in step 4,<br />

the EVAP Canister Purge Volume Control Solenoid Valve may be leaking.<br />

• Refer to the EC section of the appropriate Service Manual for inspection<br />

procedures of the EVAP Canister Purge Volume Control Solenoid Valve, DTC<br />

P1444.<br />

NOTE: The EVAP Canister Purge Volume Control Solenoid Valve is located in<br />

the engine compartment.<br />

6. Perform the DTC Confirmation Procedure for DTC P<strong>1491</strong>. Refer to the EC section of<br />

the appropriate Service Manual for confirmation procedure steps and driving conditions.<br />

7. If the DTC confirmation results are NG, do the following:<br />

a. Refer to the EC section of the appropriate Service Manual to determine if the<br />

vehicle is equipped with On-Board Refueling Vapor Recovery (ORVR).<br />

• If the vehicle has ORVR, go to b.<br />

• If the vehicle does NOT have ORVR, go to step 8.<br />

2/3

. Place a clamp on the Refueling EVAP Vapor Line near the fuel tank. The<br />

Refueling EVAP Vapor Line is the larger hose (see figure 2). Use hose clamp<br />

(3M P/N # 08556-1), found in Fuel Injector Cleaning Kit J-45701, or equivalent.<br />

c. Retry DTC Confirmation Procedure<br />

d. If the result is now OK, the Refueling Control Valve may be leaking and should<br />

be inspected. Refer to the EC section of the appropriate Service Manual for<br />

Refueling Control Valve inspection procedures.<br />

8. If the DTC confirmation is still NG after step 7, or the vehicle is not equipped with<br />

ORVR, do the following:<br />

a. Disconnect two (2) lines from the Vacuum Cut Valve. One that goes to the fuel<br />

tank and one that goes to the EVAP Canister (see figure 1).<br />

b. Use a hand <strong>vacuum</strong> pump to check each of the two (2) disconnected hoses for<br />

free flow. Make sure they are clear into the fuel tank (vent line) and into the<br />

EVAP Canister (see figure 2).<br />

NOTE:<br />

Figure 2<br />

• Figure 2 includes ORVR system. Refer to the appropriate service manual to<br />

determine if your vehicle has ORVR or not.<br />

• The lines between the Vacuum Cut Valve and Fuel Tank, and between the<br />

Vacuum Cut Valve and EVAP Canister may go through a metal line. Make<br />

sure the lines are clear between the Vacuum Cut Valve and Fuel Tank, and<br />

between the Vacuum Cut Valve and EVAP Canister, including any metal<br />

lines.<br />

c. If any blockage is found, determine the cause and repair as necessary.<br />

Blockage in either of these lines will cause a DTC.<br />

9. If all of the above checks do not locate the source of the incident, refer to the<br />

appropriate Service Manual for further DTC P<strong>1491</strong> <strong>diagnosis</strong>.<br />

3/3