Pipe Cutoff Methods - George E King Petroleum Engineering Oil and ...

Pipe Cutoff Methods - George E King Petroleum Engineering Oil and ...

Pipe Cutoff Methods - George E King Petroleum Engineering Oil and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

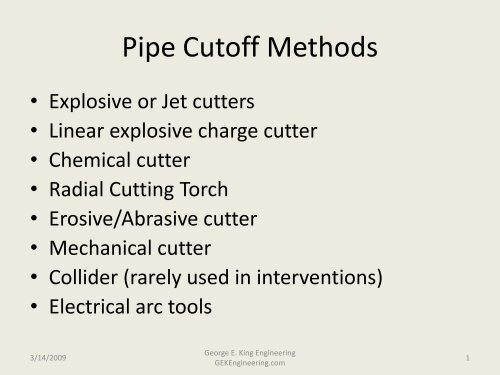

<strong>Pipe</strong> <strong>Cutoff</strong> <strong>Methods</strong><br />

• Explosive or Jet cutters<br />

• Linear explosive charge cutter<br />

• Chemical cutter<br />

• Radial Cutting Torch<br />

• Erosive/Abrasive cutter<br />

• Mechanical cutter<br />

• Collider (rarely used in interventions)<br />

• Electrical arc tools<br />

3/14/2009 1<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

<strong>Pipe</strong> <strong>Cutoff</strong> Targets<br />

• <strong>Pipe</strong>, usually tubing, when pulling a packer<br />

• Tailpipe (below a packer)<br />

• Special Targets<br />

– Multiple strings<br />

– Casing recovery<br />

3/14/2009 2<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Explosive Cutters<br />

• Continuous or segmented cutters<br />

• A variation of linear shaped charge<br />

• Needs to approach pipe ID: use a cutter with<br />

80% of pipe ID for best performance.<br />

• The charge behavior is similar to how a<br />

perforating shaped charge works.<br />

3/14/2009 3<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Shaped Charge or Explosive Cutter – note the flare remaining. The flare is a result of<br />

yielding the pipe when cut. The flared end may have to be milled away to allow the pipe<br />

to be pulled.<br />

3/14/2009 4<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Minimum flare from a well designed explosive cutter – still requires dressing to fish with an<br />

overshot.<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 5<br />

GEK<strong>Engineering</strong>.com

Cutter Problems<br />

• Large diameter cutter deployment is difficult<br />

die to restrictions in the string.<br />

• Obtaining complete pipe separation<br />

• Excessive flare at cut<br />

• Outer pipe damage<br />

3/14/2009 6<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Chemical Cutters<br />

• A focused spray of bromine trifluoride that corrodes the tubular<br />

wall. BrF 3 reacts violently on contact with water to evolve<br />

oxygen.<br />

• Application expertise is critical to success of a chemical cutter.<br />

• Field data - 75% reliable (first cut) above packer, 25% reliable<br />

below packer<br />

• Less reliability at depths beyond 10,000 ft <strong>and</strong> high alloy pipe<br />

may be more difficult to cut<br />

• Usually cuts about 95% of pipe wall – have to pull apart. Typical<br />

overpulls to part the pipe are > 30,000 lb.<br />

• Steel wool in mixing cavity believed to increase cutting efficiency.<br />

• The performance of chemical cutters is adversely affected by<br />

liquid crossflows from uneven liquid heads or pressures in the<br />

tubing <strong>and</strong> annulus.<br />

3/14/2009 7<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

A Near Note Perfect the nozzle Chemical spray pattern Cut. 50k in overpull, this 3-1/2” dropped S135 drill off immediately pipe. The nozzles when must cutter be fired. of One<br />

joint optimum in string size above <strong>and</strong> cut at optimum found backed distance off 4-1/2 from the turns inside on pulling wall of tubing. the target pipe for best<br />

performance. Small amounts of the wall may not be cut under even the best conditions<br />

<strong>and</strong> overpulls of over 50,000 lbs have been applied in some cases before the pipe finally<br />

separates.<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 8<br />

GEK<strong>Engineering</strong>.com

Chemical Cutter Guidelines<br />

• Avoid cuts in jewelry (profiles, collars, subs,<br />

m<strong>and</strong>rels <strong>and</strong> other heavy body or irregular<br />

shaped components), also avoid heavier wall <strong>and</strong><br />

higher alloy pipe when possible<br />

• The minimum restriction in a tubing string<br />

above the cut is the number 1 consideration<br />

when determining if a chemical cutter can be<br />

used. Efficiency is dramatically reduced if<br />

the cutter is used in tubing with a larger I.D.<br />

than recommended.<br />

3/14/2009 9<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Nozzle Power Falls Rapidly With Increasing St<strong>and</strong>off – The Jet is diffused with<br />

distance from the nozzle.<br />

Note: this is for a fluid jet without particles.<br />

Impact energy remaining at distances away from the nozzle.<br />

The spreading of the jet reduces the amount of chemical<br />

reacting with the cutting zone where pipe separation is<br />

needed.<br />

d<br />

93% to 99% 75% to 92% 25% to 75%<br />

6 to 8d max 9 to 15d max 16 to 24 d max<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 10<br />

GEK<strong>Engineering</strong>.com

Source unknown<br />

Chemical cutter deployment – critical pieces are max tool diameter, centralization, anchoring<br />

<strong>and</strong> tool <strong>and</strong> casing preparation. Pulling pipe tension is often necessary.<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 11<br />

GEK<strong>Engineering</strong>.com

Differential pressure effects<br />

• Chemical tool performance can be severely<br />

reduced if a pressure differential exists<br />

between inside the tubing <strong>and</strong> the annulus.<br />

• Typically, a small hole is created near the zone<br />

to be cut with a puncher charge <strong>and</strong> the<br />

pressures are allow to equalize before the<br />

pipe cut is attempted.<br />

3/14/2009<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com<br />

12

Tubing showing incomplete chemical cut<br />

The remaining steel in this example could not be yielded by overpull. Failures are<br />

due to many problems including small tool diameter, moving well fluids, deposits<br />

inside the tubing, pressure, temperature, depth <strong>and</strong> pipe grade.<br />

3/14/2009 13<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com<br />

Courtesy BP

Debris in pipe cut <strong>and</strong> pulled from a well. Debris, including pipe dope, mill scale,<br />

paraffin, scale, wireline grease, plastic coatings, etc., can be barriers to chemical<br />

cutters.<br />

3/14/2009 14<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Chemical cutter head (Beryllium Bronze) with nozzles. Nozzles wear with use – critical wells<br />

<strong>and</strong> cuts at the limit of the tool may warrant use of a new nozzle body.<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 15<br />

GEK<strong>Engineering</strong>.com

Chemical Cutter, tool cut 3.5”, 13.3 lb/ft, S-135 DP – no residual (uncut) steel was left – this<br />

was an unusually good cut.<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 16<br />

GEK<strong>Engineering</strong>.com

An experiment to measure the outside casing damage when cutting DP -

Outer casing damage by chemical cutter when DP was touching casing Wall. Depression was<br />

about 0.15” deep.<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 18<br />

GEK<strong>Engineering</strong>.com

Test of Chemical Cutter on 13.5 ppf DP - 5% metal retaining.<br />

The small uncut area, about 5% of pipe body, would require overpull to complete the pipe<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

separation 3/14/2009 in the well.<br />

19<br />

GEK<strong>Engineering</strong>.com

Chemical cut end of drill pipe, showing small uncut area broken by h<strong>and</strong> after the test.<br />

3/14/2009 20<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Chemical cut on a recovered pipe –<br />

note the nozzle impact areas <strong>and</strong> the<br />

areas that had to be pulled apart by<br />

overpull.<br />

3/14/2009 21<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Split Shot or Linear Explosive Shaped Charge<br />

• Breaks the strength of the coupling. Usually<br />

requires only minor overpull to separate<br />

unless the connection uses hook-wall threads.<br />

3/14/2009 22<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

A SplitShot charge in a coupling – the<br />

effects vary but a high success is typical.<br />

Problems:<br />

Depth control<br />

Hookwall threads<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 Courtesy Owen Tool<br />

23<br />

GEK<strong>Engineering</strong>.com

Radial Torch Cutter<br />

• Thermite plasma – extreme high temperatures<br />

(~5000 o F).<br />

• Nozzle cutter tool.<br />

• Outer string damage potential controllable in<br />

most cases.<br />

3/14/2009 24<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Troika Data<br />

• TBG - 4-1/2" 13.5# 13Cr85<br />

– 1st attempt w/chem cutter failed. Tool OD 3-<br />

1/8" - Over Pull 25K<br />

– 2nd attempt w/same tool failed- Over Pull 55K<br />

– 3rd attempt w/radial cutting torch Tool OD 2-<br />

15/16" - Over Pull 25 – pipe parted<br />

3/14/2009 25<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Courtesy BP<br />

Radial Torch Cut, 13Cr 85 ksi pipe. Note the nozzle patterns <strong>and</strong> the melted steel.<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 26<br />

GEK<strong>Engineering</strong>.com

String Shot Techniques<br />

• Aid in backoff <strong>and</strong> jump-out of coupling.<br />

• Stringshot<br />

– 1 to 4 strings of 90 grain (nominal wt) detonation<br />

cord, 3 to 4 ft long, suspended with E-line, across<br />

a coupling.<br />

– Initiated high order<br />

– Tension already pulled into pipe (25k+ overpull) or<br />

torque when doing a back-off<br />

– May not damage coupling or pin.<br />

3/14/2009 27<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Abrasive Cutting<br />

• Abrasives such as s<strong>and</strong> or pellets of carbonate<br />

carried at high velocity by water or oil can<br />

easily cut steel.<br />

• Multiple layer cuts are possible.<br />

• Control of the cut may be difficult.<br />

• Back pressure in deeper wells slows the<br />

cutting performance.<br />

• Nozzle performance less affected by st<strong>and</strong>off<br />

when using abrasives.<br />

3/14/2009 28<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Cut End of 3.5” DP, after Abrasive <strong>Cutoff</strong><br />

3/14/2009 29<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Washout in drill pipe caused by stall during abrasive jetting with a rotating tool<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 30<br />

GEK<strong>Engineering</strong>.com

Groove <strong>and</strong> washout in outer casing caused by abrasive tool<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 31<br />

GEK<strong>Engineering</strong>.com

Surface <strong>Cutoff</strong> Test of Abrasive Cutter in 2-3/8” tubing cemented in 4-1/2” . Cut required less<br />

than 20 minutes using frac s<strong>and</strong> <strong>and</strong> a rotating head nozzle tool.<br />

Courtesy Charlie Hailey<br />

Company<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 32<br />

GEK<strong>Engineering</strong>.com

Mechanical Cutters<br />

• Best choice for pipe where no tension can be<br />

pulled.<br />

• Minimize the number of cutter arms to insure<br />

good load application of cutter<br />

• Must be anchored<br />

• Slowest form of cutting – typically 1 to 10<br />

hours to get a cut.<br />

• Very experience dependent.<br />

3/14/2009 33<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com

Two bladed mechanical cutter – blades pump out with pressure – must be held out <strong>and</strong> rotated<br />

by a motor powered by the same flow.<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

3/14/2009 34<br />

GEK<strong>Engineering</strong>.com

<strong>Pipe</strong> <strong>Cutoff</strong> Conclusions<br />

• The optimum cutoff device depends on well<br />

conditions, pipe type, clearances above the<br />

cut, ability to apply overpull <strong>and</strong> operator<br />

experience.<br />

3/14/2009<br />

<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong><br />

GEK<strong>Engineering</strong>.com<br />

35