Horizontal Well Completions - George E King Petroleum ...

Horizontal Well Completions - George E King Petroleum ...

Horizontal Well Completions - George E King Petroleum ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

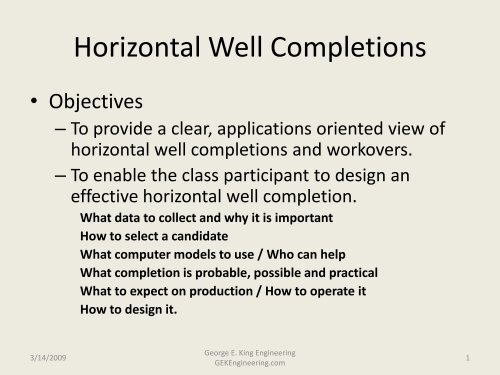

<strong>Horizontal</strong> <strong>Well</strong> <strong>Completions</strong>• Objectives– To provide a clear, applications oriented view ofhorizontal well completions and workovers.– To enable the class participant to design aneffective horizontal well completion.What data to collect and why it is importantHow to select a candidateWhat computer models to use / Who can helpWhat completion is probable, possible and practicalWhat to expect on production / How to operate itHow to design it.3/14/2009 1<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

<strong>Horizontal</strong> <strong>Well</strong>s• First conceived in US and USSR in 1930’s• First serious attempts in 1950’s• First successful completions in 1970’s• Caught on world-wide in 1980’s• Now a standard well configuration3/14/2009 2<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Slide modified from BP<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 3GEKEngineering.com

Uses of <strong>Horizontal</strong> <strong>Well</strong>s• increasing reservoir contact• water/gas coning control• water/steam injection• extended reach capability• minimizing surface locations, slot saving• improving wellbore location• prospecting and gathering reservoir info.• drain individual compartments3/14/2009 4<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Other Uses• Prospecting - as a tool to prove up seismic inan area• Accessing all parts of the field - flank wells afavorite in offshore reservoirs• As a platform for fracturing• As a “gathering system” - Amoco Canada’s “BigKahuna”3/14/2009 5<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Favorite Targets• Naturally fractured chalks and shales• Water coning problem areas• Field edges3/14/2009 6<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Best Candidates from a ReservoirPerspective• 1. Must still have good volume of reserves,pressure and fluids of value.• 2. Permeability values (horizontal and vertical)more a design consideration than a limit.• 3. Oil was thought to be a better candidatethan gas because of hydraulic fracturing,however, horizontal wells with multistagefracturing are a common completion for lowpermeability gas plays.3/14/2009 7<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Best - non stimulated candidates• No vertical barriers and generally highpermeability reservoirs.• Kv/Kh > 0.1 to 0.5 (opinion) (consider frac ifperm is too low)• natural fractures often viewed as “good”, butwatch effects on the drainage profile and alsobottom water.3/14/2009 8<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Red Flags - for unstimulatedhorizontals• Poor quality reservoirs - need something tostart with.• Very low Kv, vertical flow barriers• Some extremely thick zones3/14/2009 9<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Reservoir Considerations• Will reduced footprint help? (offshore andhigh land cost or political areas)• Will there be improvements in contact withsome dipping beds.• Pay configuration issues:– layers– boundries– anisotrophy3/14/2009 10<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Permeability Variance• K h , K H , K v• Barriers• Bed angle (a vertical well can be horizontal tothe bedding plane in some instances3/14/2009 11<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Directional Permeability<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 12GEKEngineering.com50423003

Permeability Contribution fromVertical and <strong>Horizontal</strong> Permeability<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 13GEKEngineering.com50423004

Placement of the <strong>Horizontal</strong> Above theO/W Contact• Depends on:– vertical permeability– fluid viscosities– pay zone thickness– anomolies in the zone– depth (?) and formations above the pay zone3/14/2009 15<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Pay Zone Thickness• no minimum or optimum• vertical and horizontal permeability morecritical– fractures• incidence of fractures• location of fractures• permeability of fractures• good or bad? - water???3/14/2009 16<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

When is a Multi-lateral Required?• Wherever compartmentalization reduces theability of a single wellbore (stimulation?) toeffectively and economically drain thereservoir.3/14/2009 17<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Stacked and Opposed<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 18GEKEngineering.com61934003

Compartment Recognition• Geological clues• DST’s• Production behavior• Hydrocarbon source variances (oilfingerprinting)• Early Recognition - addressed in design• Later Recognition - requires a workover3/14/2009 19<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

A two flow period test of reservoirInformation available fromdownhole gauges and flowtests.•Reservoir pressure•Perm estimates•Depletion•Barriers•Damage•Compartmentalizationpotential – what does it tell?3/14/2009<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com20

RecognizingCompartmentalizationSlide from <strong>George</strong> Tews<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 21GEKEngineering.com

<strong>Horizontal</strong> <strong>Well</strong> Expectations• Uncertainty???– can it be drilled?– can it be completed?– can it be operated/produced?– is it really a good candidate?– is fracturing needed?3/14/2009 22<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

<strong>Horizontal</strong> and Lateral Drilling• An introduction to horizontal well drillingtechnology:– Goal is to make the engineer/foreman aware ofsome problems and solutions available in drillingoperations that can have a major effect oncompletions and production.3/14/2009 23<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Types of <strong>Horizontal</strong> Kick-Off designs.Increasing the angle limits weight transfer to the bit.Long radius wellsat 2 to 6 o areused forextended reach.Medium radiuswells at 6 to 8 ominimize drillingbut lose someextensioncapacity.Short radius wellsover 8 to 10 o canmiss problemzones above thepay, but areshort.3/14/2009<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com24

Ability to Lift Cuttings• Must reach high enough velocities to carryparticles upward.– Problems in horizontals:• limited circulation rate• large annular areas = low flow velocity• striated flow regimes – especially at 30 o to 60 o• difficult in all liquid systems (rate)• difficult in all gas systems (striation)3/14/2009 25<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Cuttings Beds• Symmetric suspension - constant concentration incross section• Asymmetric suspension - all carried, but more atbottom• Moving bed - like a dune• Stationary bed - builds to height dictated by flow rate• Boycott settling - explains severe solids drop out inthe 30 to 60 degree range.3/14/2009 26<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Boycott SettlingGas Rise Rate???Vertical holes - 1000 ft/hr30 to 60 o deviation - 4000 to 7000 ft/hrRegion of greatest settlingProblems, 30 to 60 degrees – theBoycott RegionLighter fluids rise to thetop side of the wellbore(striatation) and densefluids and cuttings dropout to the bottom outof the fast movingupper fluids – result ispoor hole cleaning andsticking of strings.<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 27GEKEngineering.com

Consequences of Poor Hole Cleaning• Bridging - sticking pipe• Failure to run to bottom• Debris in perfs• Emulsions and scale “seeds” left in the well?• Cave-ins? - probably not3/14/2009 28<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Where are the casing set points inthis example?<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 29GEKEngineering.com

BUT, is it stable as the hole approaches horizontal? Rememberthat hole stability is lowest in the bend area.3/14/2009 30<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Drilling Fluid Operating “Window”• Mud density must be higher than the porepressure to keep fluids from entering the well.• Mud density must control tendency of shale tospall particles into wellbore• Mud density must be less than the formationfracture (extension) gradient – corrected forfriction pressures while circulating. The pressureexerted by the fluid at any depth is a function ofits density plus the friction pressure in thecirculating path back to the surface.3/14/2009 31<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Drilling <strong>Well</strong>bore Stability• Issues - during drilling, completion andproduction• Destabilizing Mechanism– support pressure too low (spalling)– support pressure too high (fracturing)– Rx with drilling fluids (sloughing, swelling)– formation stress unloading3/14/2009 32<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

3/14/2009 33<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

3/14/2009 34<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

A model of wellbore stability (most stressed regions in blue) of a horizontal wellbore.3/14/2009 35<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Broad Based Conclusion• Most Important Failure Factors– pore pressure prediction– weak, fissible beddling planes– low support pressures– time dependent loss of strength• Open holes best in stable formations(carbonates, clastics)• Most instability problems in the shales3/14/2009 36<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

So, how far do you drill?• Consider edge boundries• Consider drilling costs (usually low in lateral)• Consider vertical perm3/14/2009 37<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

1000Effect of length and horizontal permeabilityon PI in horizontal wellsP.I. (Mscfd/psi)10010100 1000 10000 100000 1000000Drilled length x KhHariot-Watt <strong>Horizontal</strong> Study71970001.ppt<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 38GEKEngineering.com

P.I. (Mscfd/∆m(p))100001000100Effect of horizontal well factors on PIA fieldB fieldC fieldD fieldF fieldG fieldI fieldJ fieldN field1010 100 1000 10000 100000 1000000Length x (KvKh)^0.5Hariot-Watt <strong>Horizontal</strong> Study<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 39GEKEngineering.com71970002.ppt

Undulation Problems Within the<strong>Horizontal</strong> <strong>Well</strong>How long a well can you effectively complete and produce?Depends on shape, angle, path and fluids.<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 40GEKEngineering.com50423007

Improving Artificial Lift for <strong>Horizontal</strong> <strong>Well</strong>sby Using Rat Hole on Short Radius<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 41GEKEngineering.com50423011

Production Index Factors(a comparison to horizontal well performance)• Theoritical PIF’s may range from 1 to 8.• Actual PIF’s range from 1 to about 4 or 5.• Causes:– reservoir not homogeneous– reservoir “estimates” too generous– completion design was an after-thought3/14/2009 42<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

<strong>Horizontal</strong> <strong>Well</strong> PIF’s(1300 well study)Reservoir Type PIF Average (Mean)------------------- --------------------------Conventional Reservoirs 4Heavy Oil Reservoirs 7Fractured Reservoirs 12All reservoirs comb. 5PIF = Prod. Improvement Factor: comparison ofhorizontal to vertical prod of wells at the samelocation.3/14/2009 43<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Lower Than Expected Production?• 1. Low vertical perm.• 2. Formation damage• 3. Reservoir quality variance• 4. Pressure drop along the lateral ?? - few psiat max, but can be important.• 5. Poor initial knowledge and assumptions.3/14/2009 44<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com

Pay Thickness EffectPIF54321NP = 25'NP = 50 ftNP = 75'NP = 100'NP=150'00 500 1000 1500 2000Horiz LengthPEI, Nov 97<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 45GEKEngineering.com

Effect of Kh/KvPIF654321kh/kv=1kh/kv=5kh/kv=10kh/kv=25kh/kv=5000 500 1000 1500 2000Horiz Length, ftPEI, Nov 97<strong>George</strong> E. <strong>King</strong> Engineering3/14/2009 46GEKEngineering.com

Horiz vs FracXf equivalent100080060040020000 500 1000 1500 2000horizontal <strong>George</strong> E. length, <strong>King</strong> Engineering ftPEI, Nov 97kh/kv=1kh/kv=5kh/kv=10kh/kv=25kh/kv=503/14/2009 47GEKEngineering.com

<strong>Horizontal</strong> Uses?• Consider them any time a well is designed.• Particularly good for:– Coning control,– Extending reach,– Increasing reservoir contact,– Lowering drawdown per unit area,– As a platform for multiple fracture stimulation– In some water injector projects.3/14/2009<strong>George</strong> E. <strong>King</strong> EngineeringGEKEngineering.com48