Offshore Production - George E King Petroleum Engineering Oil and ...

Offshore Production - George E King Petroleum Engineering Oil and ...

Offshore Production - George E King Petroleum Engineering Oil and ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

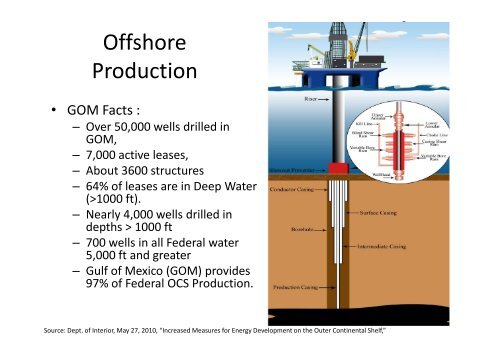

<strong>Offshore</strong><strong>Production</strong>• GOM Facts :– Over 50,000 wells drilled inGOM,– 7,000 active leases,– About 3600 structures– 64% of leases are in Deep Water(>1000 ft).– Nearly 4,000 wells drilled indepths > 1000 ft– 700 wells in all Federal water5,000 ft <strong>and</strong> greater– Gulf of Mexico (GOM) provides97% of Federal OCS <strong>Production</strong>.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

GOM <strong>Production</strong>• In 2009, GOM production accounted for 31%of total domestic oil production <strong>and</strong> 11% oftotal domestic natural gas production.• <strong>Oil</strong> production in 2009 represented the secondhighest annual production for the Gulf ofMexico OCS.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

2006 NOAA Map of 3858 <strong>Oil</strong> <strong>and</strong> GasPlatforms in the Gulf of MexicoThere have been over 50,000 wells drilled in the Gulf of Mexico. About27,000 wells have been plugged <strong>and</strong> ab<strong>and</strong>oned under DOI Regulations.

Gulf of Mexico OCS Active Leases

<strong>Offshore</strong> <strong>Production</strong> FacilitiesWikipedia

Gulf of Mexico OCS <strong>Production</strong>• Since the first major deepwaterleasing boom in 1995 <strong>and</strong> 1996, asustained <strong>and</strong> robust expansion ofdeepwater drilling activity hasoccurred, largely enabled by majoradvances in drilling technology.• In 2001, U.S. deepwater offshore oilproduction surpassed shallow wateroffshore oil production for the firsttime.• By 2009, 80% of offshore oilproduction <strong>and</strong> 45% of natural gasproduction occurred in water depths>1,000 ft, <strong>and</strong> industry had drillednearly 4,000 wells to those depths.• In 2007, a record 15 rigs were drillingfor oil <strong>and</strong> gas in water depths of5,000 feet or more in the Gulf ofMexico.• Operators have drilled about 700 wellsin water depths of 5,000 feet orgreater in the OCS.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Spill Volumes 1960 to 2010What is Typical?Barrels of <strong>Oil</strong> Spilled5,000,0004,500,0004,000,0003,500,0003,000,0002,500,0002,000,0001,500,0001,000,000500,0000DeepWaterEra99,000 106,000 7,000 2,000 18,0004,900,0001960-69 1970-79 1980-89 1990-99 2000-09 Macondoest.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

6,000,000,000<strong>Production</strong> vs. Spill VolumesBarrels of <strong>Oil</strong>Deep Water Era5,450,000,0005,000,000,0004,000,000,000<strong>Production</strong>Spilled3,455,000,000 3,387,000,0004,051,000,0003,000,000,0002,000,000,0001,460,000,0001,000,000,000099,000 106,000 7,000 2,000 18,000 4,900,00001960-69 1970-79 1980-89 1990-99 2000-09 MacondoestSource: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

OCS Blowout Events > 1,000 bbls1964-1970After these blowouts, in the period from 1971 through 2009, a total of approximately1,800 barrels was spilled on the Federal OCS as a result of blowout events. Of thatamount, 425 barrels were blowouts resulting from hurricane damage. An additional 450barrels occurred at an oil pump during production operations. Since 1956, 15 blowoutsresulted in at least one fatality; three of these events occurred after 1986.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Blowouts – what type?• Blowouts represent a type of loss of well control event that canresult in large discharges of oil into the natural environment.• Since 1970, the number of blowouts per number of wells drilled hasvaried significantly from year to year.• From 1964 through 1970, a total of approximately 178,000 barrelsof oil was spilled on the Federal OCS as a result of blowout events(see Table 2).– About 13,000 barrels resulted from blowouts related to externalforces, such as hurricanes <strong>and</strong> ship collisions.– An additional 30,000 barrels were released when a production fireresulted in the loss of well control of 12 wells on a productionplatform.– The remaining 135,000 barrels that were released during blowoutsoccurred during drilling, well completion, or workover operations.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Deep Water Statistics• Nearly 4,000 wells have been drilled in gulf water depth inexcess of 1,000 feet <strong>and</strong> 700 wells in all federal water 5,000feet or greater;• 80 % of offshore oil production <strong>and</strong> 45 percent of naturalgas production came from DW in 2009;• DW oil production surpassed shallow water production in2001.• Economic Impact– In 2009, federal offshore leasing revenue was $6 billion.– All U.S. offshore operations provide direct employmentestimated at 150,000 jobs.– Since 1953, the federal government has collected $200 billionfrom lease bonuses, fees <strong>and</strong> royalty payments from all offshoreoperators.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

<strong>Offshore</strong> Spills <strong>and</strong> Blowouts• From 1964 to 2009, 17.5 billion barrels of crude oil <strong>and</strong>condensate have been produced in federal offshore waters,while 532,000 barrels have been spilled; meaning 30.3barrels have spilled per 1 million barrels produced;• The number of spills jumped during the 2000-2009 decadeto 72 from 15 in the 1990s <strong>and</strong> the amount of oil spilledjumped to 18,000 barrels from 2,000 barrels in the 1990s.• Seven offshore blowouts occurred in federal waters from1964 to 1970 that resulted in spills exceeding 1,000 barrels.Since 1971, blowout events have resulted in only 1,800barrels of spilled oil.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Historical Spills?Very Small Prior to April 2010• The last major incident resulting in oil coming ashorefrom a blowout in the US OCS occurred 41 years ago, in1969. From 1970 until April 2010, a total of 1,800barrels of oil spilled due to blowouts. Allmeasurements of safety have shown a steady level ofimprovement since modern Minerals ManagementService regulations came into effect in 1970.• The safety record in the Gulf of Mexico for offshoreworkers is much better than that of the average workerin the US, <strong>and</strong> the amount of oil spilled is significantlyless than that of commercial shipping or petroleumtankers.Source: Society of <strong>Petroleum</strong> Engineers,SPE Notes, July 6, 2010

Historical US GOM Spills?Very Small Prior to April 2010• The last major incident resulting in oil coming ashore from a blowout inthe US OCS occurred 41 years ago, in 1969. From 1970 until April 2010, atotal of 1,800 barrels of oil spilled due to blowouts. All measurements ofsafety have shown a steady level of improvement since modern MMSregulations came into effect in 1970. (SPE Notes, July 6, 2010)• The GOM safety record for offshore workers is much better than that ofthe average worker in the US, <strong>and</strong> the amount of oil spilled from wells hasbeen significantly less than that of commercial shipping or petroleumtankers. (SPE Notes, July 6, 2010)• Over the past 45 years (to end 2009), 17.5 billion barrels of crude oil <strong>and</strong>condensate have been produced in US federal offshore waters, while532,000 barrels have been spilled, meaning 30.3 barrels have spilled per 1million barrels produced (US DOI Statistics, May 27, 2010 report & Reuters, June 4, 2010).• Natural Seeps, during the same 45 year time period, flowed an estimated50 million barrels of oil into US waters from natural subsea seeps (most inGOM <strong>and</strong> Southern California) (Source: <strong>Oil</strong> in the Seas III)SPE Notes can be found at www.spe.org<strong>Oil</strong> in the Seas III, National Research Council of the National Academies), 2003

How Big is The Recent Spill?(<strong>Engineering</strong> Estimates of 4.9 Million Barrels?)• The Macondo blowout is the largest offshore oil spill inUS history. It is not the largest spill in world history,nor the largest spill in US history.• The largest spill in world history was likely during the1991 gulf war, when the Iraqi army caused between 5.5<strong>and</strong> 11 million barrels to be released.• The largest spill in US history was onshore in Kern,California, when 9 million barrels was spilled onshorein 1910 <strong>and</strong> 1911.• The largest spill to 2010 in the Gulf of Mexico was the1979-1980 Ixtoc well blow out in Mexican waters. Thatwell released between 3.3 <strong>and</strong> 3.5 million barrels.Source: Society of <strong>Petroleum</strong> Engineers,SPE Notes, July 6, 2010

Why So Slow?• The very low rate of spills from wells in theGulf caught everyone off guard.• The Macondo accident is unprecedented,<strong>and</strong> comprehensive studies of methodsfor more rapid <strong>and</strong> effective responses to apotential deepwater blowout are beingundertaken.• A rapid response effort has been proposed<strong>and</strong> funded by industry.• The offshore industry has learned fromthis incident <strong>and</strong> is making changes inoperating practices, training <strong>and</strong>equipment to ensure that we are betterprepared to h<strong>and</strong>le a subsea flow from afailed blowout preventer <strong>and</strong> riser. (SPE Notes,July 6, 2010)

What Changes Are Needed• Safety can be increased quickly with theimplementation of safety recommendations made bythe US Department of Interior, including verifyingcompliance with existing regulations <strong>and</strong> a NationalSafety Alert, recertification of all BOP equipment, <strong>and</strong>new casing <strong>and</strong> cement design requirements.• Additional safety requirements have been proposed forimplementation within one year, including taking afresh look at how to deal with a deepwater blowout.• Other changes may be recommended after theaccident investigation is completed, <strong>and</strong> the rootcauses of the blowout are determined.Source: Society of <strong>Petroleum</strong> Engineers,SPE Notes, July 6, 2010

Basis of the Moratorium• While the rate of blowouts per well drilled hasnot increased, even as more activity hasmoved into deeper water, the experience withthe BP <strong>Oil</strong> Spill illustrates the significantchallenges in containing a blowout indeepwater, as compared to containing ablowout in shallower water.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

What is the Impact of theMoratorium?• The moratorium provides time for DOI to ensure new procedures are inplace to make operations safer. DOI organized a group of expertreviewers <strong>and</strong> contributors who agreed to a list of recommendations tomake drilling safer. Some of these recommendations take time to study<strong>and</strong> adopt into regulations to assure compliance. In some cases the timeframes may be as long as 6 months <strong>and</strong> even longer in one or two cases.• However, a drilling moratorium can itself create additional safety risks.– Forcing existing drilling operations to stop as soon as possible withoutfinishing the drilling of wells. Discontinuous operations can increase risk.– It is possible that the best rigs could leave the GOM first <strong>and</strong> come back last,creating a negative impact on the overall quality of the fleet.– Ceasing operations for six months <strong>and</strong> longer could lead to a loss ofexperienced drilling staff. Staff experience is a key factor in safe operations.– More crude oil would have to be imported by tanker <strong>and</strong> the risk of spillsduring tanker transport is greater than from drilling.Source: Society of <strong>Petroleum</strong> Engineers,SPE Notes, July 6, 2010

Is Deepwater <strong>Production</strong> That Important?• In 2009, production from US OCS accounted for 31 % of total domestic oilproduction <strong>and</strong> 11 percent of total domestic, marketed natural gas production.• Deepwater development is a key component of the US’s energy supply, with 80percent of US OCS offshore oil production <strong>and</strong> 45 percent of US OCS natural gasproduction in water depths greater than 1,000 feet.• The deepwater GOM supplied approximately 25 percent of the US’s domestic oil<strong>and</strong> 14 percent of its domestic gas production in 2009. The 20 most prolificproducing blocks in the GOM are located in deepwater.• While drilling at depths of 5,000 feet or more was almost unheard-of 20 years ago,about 6 percent of world oil production now comes from deepwater wells,according to research from IHS Cambridge Energy Research Associations (CERA) on“The Role of Deepwater <strong>Production</strong> in Global <strong>Oil</strong> Supply.” <strong>Offshore</strong> oil is expectedto make up some 40 percent of world production at the end of this decade.• Globally, 14,000 deepwater wells have been drilled. In 2008, the total amount ofoil <strong>and</strong> natural gas discovered in deep water globally exceeded the volume foundonshore <strong>and</strong> in shallow water combined, according to CERA.Source: Society of <strong>Petroleum</strong> Engineers, SPE Notes, July 6, 2010

What About the Remaining <strong>Oil</strong>?• Damage estimates vary widely from “WorldEnding Scenario” to moderate.• Cleanup will take time.• Real Time Information Is Available:– What can be learned from previous spills?– What can be learned from the thous<strong>and</strong>s ofnatural oil seeps?

Natural <strong>Oil</strong> Seeps inthe Sea• How much is there?• Where did it come from?• What will it do?• What is the effect longterm?• Can it be totally stopped?Geology.com

How Much <strong>Oil</strong> is There?Data to 2003• 76,000,000 gallons (1.8 million barrels) enterNorth American waters every year <strong>and</strong>380,000,000 gallons (9 million barrels) enterthe world’s waters every year.• Four Sources:– Natural Seeps– <strong>Petroleum</strong> Extraction– <strong>Petroleum</strong> Transportation– <strong>Petroleum</strong> ConsumptionData from: <strong>Oil</strong> in the Sea III, Committee on <strong>Oil</strong> in the Sea, National Research Council of theNational Academies, The National Academic Press, Washington DC, 2003.

North America• Natural Seeps – 62% - 47,000,000 gal/yr– Principally, GOM, California, Alaska, Canada• <strong>Petroleum</strong> Extraction – 1% - 880,000 gal/yr (to 2009)– This is NOT trivial since it is often released in mass• <strong>Petroleum</strong> Transport – 4% - 2,700,000 gal/yr– Again, not trivial• <strong>Petroleum</strong> Consumption – 33% - 25,000,000 gal/yr– Cars, boats, parking lots, roads, roofsData from: <strong>Oil</strong> in the Sea III, Committee on <strong>Oil</strong> in the Sea, National Research Council of theNational Academies, The National Academic Press, Washington DC, 2003.

Natural Seeps• Natural seepage from geologic formations below the seafloor to theseas off North America exceeds 47,000,000 gallons each year <strong>and</strong>worldwide 180,000,000 gallons each year.• Natural seeps therefore flow over 60% of the oil into the seas inNorth America <strong>and</strong> 45% of the oil worldwide.• In North America, the largest <strong>and</strong> best known seeps appear to berestricted to the Gulf of Mexico <strong>and</strong> the waters off SouthernCalifornia. These regions also have extensive oil <strong>and</strong> gas production.• Many of these oil seeps were known (<strong>and</strong> used by nativeAmericans) since the 17 th century.• Areas around seeps are extremely important laboratories forunderst<strong>and</strong>ing crude oil behavior in the environment as well as howmarine life responds to the introduction of petroleum.Data from: <strong>Oil</strong> in the Sea III, Committee on <strong>Oil</strong> in the Sea, National Research Council of theNational Academies, The National Academic Press, Washington DC, 2003.

• Who inspects what?Extra Slides

Review of Application for Permit to Drill (APD)• DOI conducts an engineering review of the APD. Checks:– proposed drilling rig’s maximum operating limits for drilling depth <strong>and</strong> water depth– proposed procedure, including assessment of best available <strong>and</strong> safest technology– well location <strong>and</strong> directional program,– geological <strong>and</strong> geophysical hazards,– subsurface environment for pore pressure <strong>and</strong> fracture gradient,– wellbore design <strong>and</strong> schematic,– design calculations for pressure containment during drilling <strong>and</strong> completion,– cement volumes, <strong>and</strong> testing pressures for the well control equipment, casing <strong>and</strong> casingshoe.– hurricane risk assessment is performed during hurricane season.– how the proposed operation satisfies regulations in meeting its objective of safely reaching atarget depth. Including an assessment of:• well casing setting depths determined by formation strength, predicted formation fluid pressure,drilling mud weight limits, any anticipated subsurface hazards;• effectiveness of well casing strength for pressure containment at its specified depth;• effectiveness of cementing the well casing after successfully securing <strong>and</strong> isolating the hydrocarbonzones or any encountered subsurface hazards; <strong>and</strong>• maintaining well control by adjusting drilling mud properties <strong>and</strong> the use of well control equipmentsuch as diverters <strong>and</strong> BOPs.Upon completing the engineering review, the Department may approve the APDwith conditions if warranted, return it to the operator for modifications, or deny it. Ifthe applicant makes changes to the drilling application, the Department must grantapproval before the applicant performs its work.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

DOI MMS Rig Inspections• The Department maintains a comprehensive inspectionprogram to promote the safety of offshore oil <strong>and</strong> gasoperations on the OCS.• This program places inspectors offshore on drilling rigs <strong>and</strong>production platforms to enforce operator compliance withFederal safety <strong>and</strong> environmental protection requirements.• When a drilling rig enters Federal waters to drill a well,Federal inspectors will meet the rig where it is moored toprovide training to the rig operators about the Federalregulatory structure. At this time, inspectors will conduct adrilling inspection of the equipment.• It is Departmental policy for inspectors to inspect the rigonce on location every 30 days.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Inspections - Platforms• For production platforms, it is practice for initialinspections to take place during the fabrication ofthe platform at a shipyard.• Federal inspectors <strong>and</strong> engineers review the flowdiagrams <strong>and</strong> charts to determine if the specificfacility meets regulatory requirements.• A complete production inspection of the facilityoccurs typically about 30 to 45 days after aproduction platform is installed.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Inspections - Producing Platforms• After operations begin, the Department conductsadditional announced <strong>and</strong> unannounced inspections.• Inspectors typically give the operator a few days notice forannounced inspections.• Inspectors also fly to platforms or rigs unannounced, <strong>and</strong> insuch cases, inspectors contact the operator as theyapproach the facility.• These unannounced inspections foster a climate of safeoperations, maintain an inspector presence, <strong>and</strong> allowregulators to focus on operators with a poor performancerecord.• They are also conducted after a critical safety feature haspreviously been found defective during previousinspections or by operator reporting.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Inspections - Drilling1. a general safety walk through of the facility looking for general housekeeping hazards related toslips/trips/falls/railings/open gratings;2. verification of the location of gas detectors/hydrogen sulfide detectors/mud volume detectors;3. verification that the mud trip tank is operational <strong>and</strong> properly marked (graduated), that appropriate quantities of a mudweighting material are onboard (barite), <strong>and</strong> that the drilling mud currently in use has been periodically tested <strong>and</strong> is of theproper density as indicated in the APD (viewing mud logger’s report);4. verification that proper well control data relative to the well depth <strong>and</strong> type of tubulars (drill pipe, casing) in the well isclearly marked <strong>and</strong> posted on the rig floor <strong>and</strong> that there are remote BOP <strong>and</strong> Diverter control panels on the facility;5. verification that equipment is properly grounded <strong>and</strong> that drill string safety valves with proper wrenches for the diameter ofdrill pipe or casing currently in the well are located on the drill floor in an open position <strong>and</strong> within easy access to rigpersonnel;6. verification that the crown block safety device is installed <strong>and</strong> operational <strong>and</strong> that fresh air intakes are properly located onthe rig;7. verification that diesel engines have required shut down devices, that breathing air is properly labeled, that engine exhaustis insulated;8. verification that crane load charts on platform rigs have been recorded, that all equipment has proper catchbasins/drains/curbs/gutters/drip pans, that the facility is properly marked as to location, that the facility is properly lighted;9. if drilling is being conducted on a production facility, verification that there is an operational Emergency Shut Down deviceon the rig floor;10. verification of the status/switch position of the BOP pumps that the st<strong>and</strong>-by pump operates in an automatic fashion, thatthe accumulator bottles are in service;11. review the BOP tests records;12. checks the Subpart O well control status of contractor <strong>and</strong> lessee employees;13. checks for certain Potential Incidents of Noncompliance, which allow the inspector to check for general competency relatedto drilling operations; <strong>and</strong>14. inspectors may test, r<strong>and</strong>omly or as a result of a safety concern, an offshore employee’s competency with various safetydevices.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Inspections by MMS GOM Region in 2009• 561 drilling inspections;• 3,678 production inspections;• 268 well workover & completion inspections;• 6,804 meter inspections;• 82 ab<strong>and</strong>onment inspections;• 4,837 pipelines inspections; <strong>and</strong>• 3,342 personal safety inspections, on behalf of the U.S.Coast Guard.Source: Dept. of Interior, May 27, 2010, “Increased Measures for Energy Development on the Outer Continental Shelf,”

Inspections - PINC• DOI maintains a National Potential Incident ofNoncompliance (PINC) List to help inspectors carry outenforcement actions: it contains a checklist ofrequirements for specific installations or procedures <strong>and</strong>prescribed enforcement actions consisting of writtenwarnings, shut-in of a component, including wells,equipment, or pipelines, or shut-in of an entire platform.• When noncompliance with the National PINC is detected<strong>and</strong> if the violation does not impose an immediate dangerto personnel or equipment, a warning Incident ofNoncompliance (INC) is issued.• An INC must be corrected within 14 days from the timespecified on the INC, <strong>and</strong> the operator may not continuethe activity in question until it has corrected the INC.

DOI FundedStudies on DeepWaterSource: Dept. of Interior, May 27, 2010, “Increased Measures forEnergy Development on the Outer Continental Shelf,”