Locating a Tubing Leak - George E King Petroleum Engineering Oil ...

Locating a Tubing Leak - George E King Petroleum Engineering Oil ...

Locating a Tubing Leak - George E King Petroleum Engineering Oil ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

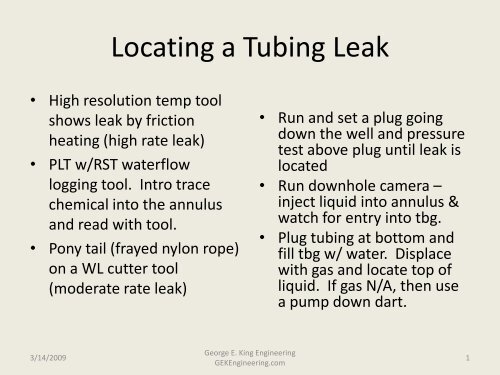

<strong>Locating</strong> a <strong>Tubing</strong> <strong>Leak</strong>• High resolution temp toolshows leak by frictionheating (high rate leak)• PLT w/RST waterflowlogging tool. Intro tracechemical into the annulusand read with tool.• Pony tail (frayed nylon rope)on a WL cutter tool(moderate rate leak)• Run and set a plug goingdown the well and pressuretest above plug until leak islocated• Run downhole camera –inject liquid into annulus &watch for entry into tbg.• Plug tubing at bottom andfill tbg w/ water. Displacewith gas and locate top ofliquid. If gas N/A, then usea pump down dart.3/14/2009 1<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>GEK<strong>Engineering</strong>.com

Detection of CrossflowProblem orInformation NeededRec. Logging ToolsProcedure/Level of DetailDetection ofCrossflow orUndergroundBlow outTemperatureSurveyNoise LogOxygenActivation SurveyDifference in slope of temperature gradient – willdetect flow rates down to 25 BPD if liquid andtemperatures of fluids are different. Figures ontemperature vs. flow distance help estimate waterflow in the annulus.Best performance of noise logs is with gas flow.Gas flow to about 10 actual ft 3 /D (Note – notstandard ft 3 /day). At very low gas flow rates(q

Location of Cement TopProblem orInformation NeededRec. Logging ToolsProcedure / Level of DetailLocation of CementTopTemperatureSurveyOK if run within 12 to 24 hrs of cement job. Littletemperature variation with the formation maymake cement top difficult to see.CBL (cementbond log)Best results after 3 days or when cement hasdeveloped 70%+ of the compressive strength.These tools may be too large for slim hole wells.Gravel-packlogging (GR)Tool response depends on density differencebetween cement and annular fluid.3/14/2009 3<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>GEK<strong>Engineering</strong>.com

Casing InspectionProblem orInformationNeededDetection ofcasing wearfrom drillingRec. Logging ToolsE-line calipersEM – eddycurrent tool thatmeasures wallthicknessAcoustic wall thicknesstoolProcedure / Level of DetailMulti-arm calipers generally good, but slick linecalipers may rotate and “over-report” the badspots.Highly accurate if the hole is filled with a nonconductive fluid.Qualitative indicators of wear (thickness numbersare not very accurate)3/14/2009 5<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>GEK<strong>Engineering</strong>.com

Determination of External Casing CorrosionProblem orInformationNeededRec. Logging ToolsLevel of DetailDetect casingcollapseEM – eddycurrent wallthickness surveyGravel-pack (GR –density)Investigation is to 8 to 10” radius. Investigationability falls off after the first string encountered.Qualitative investigation. Splits are more difficultto see.Depth of investigation depends on sourcestrength – may range from 4” to 16”. Splits aremore difficult to see.3/14/2009 6<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>GEK<strong>Engineering</strong>.com

Flow Behind PipeProblem orInformationNeededAnnular FlowRec. Logging ToolsTemperatureSurveyOA - oxygenactivationNoise loggingProcedure / Level of DetailUseful where the well has active annular flow.Can spot flows on the order of 1 bpd (after 24 hrs)if temperature of formation at measurement andsource of water is sufficiently different. Twosurveys, 12 hrs apart is usually adequate to spotpresence of a channel.Accurate, but don’t swap out muds. Migration offluids in pipe may be seen as “channel”.Accuracy depends on channel variations toaccelerate flow and change sound.3/14/2009 7<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>GEK<strong>Engineering</strong>.com

Problem orInformationNeededDetermineannular flowin injectorDetermination of Flow Behind Pipe for InjectorRec. Logging Tools Procedure / Level of DetailRA Tracer Survey -inject slug of I-131in brine.Track from surface to annulus until slug iscompletely pumped away. Track any flow thatgoes behind pipe and moves up.OA- oxygenactivation surveyTemperature surveyNot as reliable as the chemical tracer, due tofluctuations in the injection rate.Three temperature surveys are needed: one beforeannular injection (base line), one during and one 4 to 6hours after injection (decay).Borax LogPumping borax/water solution down tbg into the liner,allowing mix to invade perfs & any channels incasing/formation annuli. Initial pass, before borateinjection, is w/ Pulsed Neutron log (no Borax), followedby passes at 20bbls, 40bbls, and 60bbls as borax mixpumped. Borax affects neutron capture, leaving acharacteristic signature. Overlays of the Sigma/CNLcounts reveal the zones of borax penetration, andidentifies channels taking fluid.<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>3/14/2009 8GEK<strong>Engineering</strong>.com

Location of Annular <strong>Leak</strong>Problem orInformation NeededRec. Logging ToolsProcedure / Level of DetailCertificationfor annulardisposalRadioactive TracerSurvey with RAisotope in brine,pumped into annuluswhile logging with aGR tool in tubing.Oxygen activationsurveyTemperature surveyCan distinguish entry points and limited detailon up or down movement of the inject slug.Not as accurate as RA logging. Fluctuations inrate create problems.Can determine channels and entry points.Needs 3 runs – before, during and after.Borax LogPumping borax/water solution down tbg into the liner,allowing mix to invade perfs & any channels incasing/formation annuli. Initial pass, before borate injection,is w/ Pulsed Neutron log (no Borax), followed by passes at20bbls, 40bbls, and 60bbls as borax mix pumped. Boraxaffects neutron capture, leaving a characteristic signature.Overlays of the Sigma/CNL counts reveal the zones of boraxpenetration, and identifies channels taking fluid.<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>3/14/2009 9GEK<strong>Engineering</strong>.com

Problem orInformationNeededLocation of leakto annulus orcrossflow behindpipeLocation of Source of Annular <strong>Leak</strong>Rec. Logging Tools Procedure / Level of DetailTemperaturesurveyNoise logOxygen activationlogBorax LogRelatively accurate at rates of at 1 bpd or more. Needminimum of 2 runs, before and during injection. A thirdrun may help define a qualitative level of leak rate. Runat 1 o F/in sensitivity. Will not see small gas leak ratesthrough liquid.Best for gas leak detection. Run static log and then againduring flow or negative test. Upward gas movement(percolation) at actual 10 ft3/D or more should bedetectable.Can detect flows of 20 to 40 bpd in the annulus of asingle string well if the leak is directly opposite the tool.Resolution drops to >200 bpd when two strings arepresentPumping borax/water solution down tbg into the liner,allowing mix to invade perfs & any channels incasing/formation annuli. Initial pass, before borateinjection, is w/ Pulsed Neutron log (no Borax), followedby passes at 20bbls, 40bbls, and 60bbls as borax mixpumped. Borax affects neutron capture, leaving acharacteristic signature. Overlays of the Sigma/CNLcounts reveal the zones of borax penetration, andidentifies channels taking fluid.<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>3/14/2009 10GEK<strong>Engineering</strong>.com

Channel Detection Behind Pipe• Channel logging, with borax solution injection, isaccomplished by pumping the solution down the tubing intothe liner, allowing the mix to infiltrate the perforations andany channels in the casing formation annuli.• The initial pass, before borate injection, is made with a thrutubingPulsed Neutron logging (or memory neutron) base pass(no Borax), followed by subsequent passes at 20bbls, 40bbls,and 60bbls as the borax solution is pumped away.• The borax affects neutron capture, leaving a characteristicsignature. Overlays of the Sigma/CNL counts reveal the zonesof borax penetration, and identify the channels taking fluid.3/14/2009 11<strong>George</strong> E. <strong>King</strong> <strong>Engineering</strong>GEK<strong>Engineering</strong>.com

Comparison of a memory CNL and PNL method. Achannel is apparent in the pre and post squeezelogging tracks.In some cases, the borax logging technique issufficiently robust to complement or replacetemperature logging when looking for behind the pipechannels. (SPE 25383 for Borax logging)The technique has not been used widely outsideAlaska, due to the problems in making the “BoraxBrew” and keeping it hot to avoid precipitation of theBorax at colder temperatures (