Guidebook for Energy Efficiency in Municipalities

Guidebook for Energy Efficiency in Municipalities

Guidebook for Energy Efficiency in Municipalities

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Energy</strong> efficiency and the build<strong>in</strong>g envelope<br />

T2<br />

Apart from reduc<strong>in</strong>g energy consumption, the benefits of an energy-efficient build<strong>in</strong>g<br />

envelope <strong>in</strong>clude:<br />

lower cost of air-condition<strong>in</strong>g plant, as smaller quantities of heat<strong>in</strong>g and cool<strong>in</strong>g are<br />

required at peak periods (often, the capital sav<strong>in</strong>gs on HVAC plant can almost pay <strong>for</strong><br />

the extra cost of <strong>in</strong>sulation and other energy-efficient features—be<strong>for</strong>e the value of<br />

ongo<strong>in</strong>g energy sav<strong>in</strong>gs is even considered);<br />

lower charges <strong>for</strong> peak energy demand;<br />

improved occupant com<strong>for</strong>t.<br />

The energy efficiency of an exist<strong>in</strong>g build<strong>in</strong>g envelope can be improved by a variety of<br />

measures. While this may not save on <strong>in</strong>vestment <strong>in</strong> heat<strong>in</strong>g and cool<strong>in</strong>g plant, it can still<br />

cut peak energy demand charges, reduce operat<strong>in</strong>g costs and improve occupant com<strong>for</strong>t.<br />

For example, where air-condition<strong>in</strong>g equipment is be<strong>in</strong>g converted to elim<strong>in</strong>ate the use of<br />

CFCs, the replacement refrigerants may have different properties, and this may reduce<br />

the cool<strong>in</strong>g capacity of the plant. Rather than <strong>in</strong>vest<strong>in</strong>g <strong>in</strong> extra equipment to compensate<br />

this, upgrad<strong>in</strong>g the energy efficiency of the build<strong>in</strong>g envelope is a good alternative, as this<br />

option also reduces peak capacity requirements and cuts ongo<strong>in</strong>g energy costs as well.<br />

Constra<strong>in</strong>ts to overcome<br />

Ef<strong>for</strong>ts to improve the thermal per<strong>for</strong>mance of a build<strong>in</strong>g are often treated as a low priority<br />

<strong>for</strong> a number of reasons:<br />

Build<strong>in</strong>g design is the responsibility of the architect, while eng<strong>in</strong>eers look after HVAC<br />

design (<strong>in</strong>clud<strong>in</strong>g calculation of heat<strong>in</strong>g and cool<strong>in</strong>g loads, which provides valuable<br />

<strong>in</strong><strong>for</strong>mation about which elements of the build<strong>in</strong>g envelope contribute most to heat<strong>in</strong>g<br />

and cool<strong>in</strong>g energy consumption and peak demand). Often communication between<br />

the two is poor. Appropriate contractual arrangements and/or use of a project<br />

manager or coord<strong>in</strong>ator can overcome this.<br />

HVAC designers are often paid a percentage of the cost of the HVAC system, so they<br />

have no <strong>in</strong>centive to help the architect reduce HVAC size and cost.<br />

Many designers believe that an energy-efficient build<strong>in</strong>g envelope may <strong>in</strong>crease<br />

energy consumption by trapp<strong>in</strong>g heat generated by lights, equipment, and people<br />

<strong>in</strong>side the build<strong>in</strong>g.<br />

<strong>Energy</strong> efficient build<strong>in</strong>g design is perceived to be expensive, but the appropriate<br />

orientation, siz<strong>in</strong>g, and selection of glaz<strong>in</strong>g can actually reduce envelope costs.<br />

Opportunities <strong>for</strong> sav<strong>in</strong>gs<br />

Sav<strong>in</strong>gs on HVAC operat<strong>in</strong>g costs (and greenhouse emissions) through energy-efficient<br />

build<strong>in</strong>g design can range from 20 to 50%.<br />

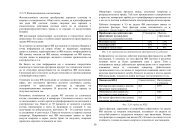

Glaz<strong>in</strong>g<br />

Up to a kilowatt of heat can enter a build<strong>in</strong>g through a square metre of clear glass<br />

exposed to direct sun, which is equivalent to switch<strong>in</strong>g on a s<strong>in</strong>gle-bar electric heater at<br />

the hottest time of the day. W<strong>in</strong>ter heat loss through each square metre of s<strong>in</strong>gle glaz<strong>in</strong>g<br />

is three times that through un<strong>in</strong>sulated wall, and more than 10 times the loss through a<br />

square metre of <strong>in</strong>sulated wall. This adds to peak electricity demand (often <strong>in</strong>curr<strong>in</strong>g extra<br />

demand charges), requires <strong>in</strong>creased HVAC system capacity, and creates glare and<br />

occupant discom<strong>for</strong>t.