LOCATOR® BAR ATTACHMENT SYSTEM - Proscan

LOCATOR® BAR ATTACHMENT SYSTEM - Proscan

LOCATOR® BAR ATTACHMENT SYSTEM - Proscan

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

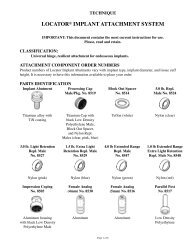

TECHNIQUE<br />

LOCATOR ® <strong>BAR</strong> <strong>ATTACHMENT</strong> <strong>SYSTEM</strong><br />

IMPORTANT: This document contains the most current instructions for use.<br />

Please, read and retain.<br />

CLASSIFICATION:<br />

Universal hinge, resilient attachment for bar splinted endosseous implants.<br />

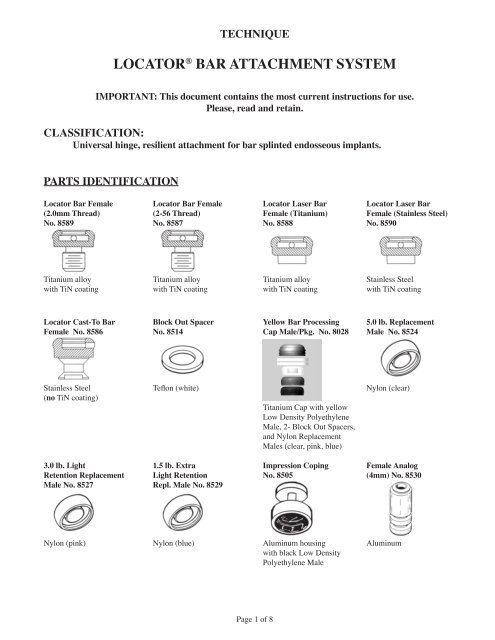

PARTS IDENTIFICATION<br />

Locator Bar Female Locator Bar Female Locator Laser Bar Locator Laser Bar<br />

(2.0mm Thread) (2-56 Thread) Female (Titanium) Female (Stainless Steel)<br />

No. 8589 No. 8587 No. 8588 No. 8590<br />

Titanium alloy Titanium alloy Titanium alloy Stainless Steel<br />

with TiN coating with TiN coating with TiN coating with TiN coating<br />

Locator Cast-To Bar Block Out Spacer Yellow Bar Processing 5.0 lb. Replacement<br />

Female No. 8586 No. 8514 Cap Male/Pkg. No. 8028 Male No. 8524<br />

Stainless Steel Teflon (white) Nylon (clear)<br />

(no TiN coating)<br />

Titanium Cap with yellow<br />

Low Density Polyethylene<br />

Male, 2- Block Out Spacers,<br />

and Nylon Replacement<br />

Males (clear, pink, blue)<br />

3.0 lb. Light 1.5 lb. Extra Impression Coping Female Analog<br />

Retention Replacement Light Retention No. 8505 (4mm) No. 8530<br />

Male No. 8527 Repl. Male No. 8529<br />

Nylon (pink) Nylon (blue) Aluminum housing Aluminum<br />

with black Low Density<br />

Polyethylene Male<br />

Page of 8

Parallel Post Yellow Bar Processing Locator Core Tool Locator Paralleling<br />

No. 8517 Replacement Male No. 8393 Mandrel No. 9107<br />

No. 8026<br />

(Male Removal Tool,<br />

Male Seating Tool, &<br />

gold-plated Abutment Driver)<br />

Low Density<br />

Polyethylene (black)<br />

Low Density<br />

Polyethylene (yellow)<br />

1.7mm Bar Drill 2.0mm Bar Tap 1.8mm Bar Drill 2-56 Bar Tap<br />

(2.0mm Thread) (2.0mm Thread) (2-56 Thread) (2-56 Thread)<br />

No. 9102 No. 9104 No. 9103 No. 9105<br />

Drill & Tap Holder 2.0mm Castable 2-56 Castable<br />

No. 8016 Threaded Insert Threaded Insert<br />

No. 8014 No. 8013<br />

INDICATIONS<br />

The Locator Bar Attachment System is designed for use with overdentures or partial dentures retained in<br />

whole or in part by bar splinted endosseous implants in the mandible or maxilla.<br />

CONTRAINDICATIONS<br />

Not appropriate where a totally rigid connection is required.<br />

CAUTION<br />

Federal (U.S.A.) law restricts this device to sale by or on the order of a licensed dentist.<br />

STERILIZATION<br />

All components and instruments are supplied NON-STERILE. Tools and metal instruments may be<br />

sterilized following standard clinical procedures, prior to use.<br />

FEATURES<br />

1. LOWEST VERTICAL HEIGHT: The total height of the Locator Bar Attachment (abutment plus<br />

male) is only 2.5mm on a cast alloy bar.<br />

2. LOCATING DESIGN: Self-locating design allows a patient to easily seat their overdenture without the<br />

need for accurate alignment of the attachment components.<br />

3. RETENTION INSIDE AND OUT: The patented Dual Retention innovation provides the Locator<br />

Attachment with greater retention surface area than ever before available with other attachments. A<br />

combination of inside and outside retention ensures the longest lasting performance.<br />

4. ROTATIONAL PIVOTING ACTION: The design of the pivoting Locator Male allows a resilient<br />

connection for the prosthesis without any resulting loss of retention. The retentive nylon male remains<br />

Page of 8

completely in contact with the abutment socket while its metal denture cap has a full range of rotational<br />

movement over the male.<br />

5. CHOICE OF FOUR TECHNIQUES: The Locator Bar Attachment can be placed by any of the four<br />

popular techniques used by Dental Laboratories to fabricate an implant retained bar with attachments:<br />

1. Cast a Castable Threaded Insert into a bar for a removable threaded Locator Bar Female connection.<br />

2. Drill and tap the bar for a threaded Locator Bar Female.<br />

3. Laser weld a Locator Laser Bar Female to the bar.<br />

4. Cast-to the stainless steel Locator Cast-To Bar Female with gold alloy.<br />

A. PLACEMENT OF THE LOCATOR <strong>BAR</strong> <strong>ATTACHMENT</strong><br />

The Locator Bar Attachment can be placed by any choice of the four following techniques used by a Dental<br />

Laboratory to fabricate a bar with dental attachments. CAUTION: The most critical consideration in the<br />

proper placement of the Locator Bar Attachment on a milled or cast bar is that a minimum of 1.0mm<br />

of bar material remains between the edge of a UCLA type screw retaining the bar and the Locator<br />

Bar Female, or a minimum of 5.0mm between the edges of multiple placed Locator Bar Females<br />

that is required to avoid interference of the Locator Titanium Denture Caps. (Locator Bar Female =<br />

4.0mm Diameter, Locator Denture Cap = 5.5mm Diameter).<br />

Technique to cast a Castable Threaded Insert into a bar for a removable threaded Locator Bar Female<br />

1. A) Parts needed – New Case:<br />

(8014) 2.0mm Castable Threaded Insert<br />

(8589) Locator Bar Female (2.0mm Thread)<br />

(9104) 2.0mm Bar Tap (2.0mm Thread)<br />

(8016) Drill and Tap Holder<br />

B) Parts needed – Replace TSB Ball Attachment:<br />

(8013) 2-56 Castable Threaded Insert<br />

(8587) Locator Bar Female (2-56 Thread)<br />

(9105) 2-56 Bar Tap (2-56 Thread)<br />

(8016) Drill and Tap Holder<br />

2. The 2.0mm Castable Threaded Insert (Zest order #8014) and a 2.0mm Bar Tap (Zest order #9104) are<br />

used for creating the threaded site in a cast alloy bar.<br />

3. Survey and set a delrin Castable Threaded Insert into the wax pattern of the bar at each site where a<br />

Locator Bar Attachment is needed. The top of the Threaded Insert should be flush with the top surface of<br />

the surrounding bar pattern.<br />

4. The delrin Castable Threaded Insert will become part of the cast alloy bar when the bar pattern is cast<br />

using standard casting procedures.<br />

5. Insert and tighten the 2.0mm Bar Tap into the Drill & Tap Holder (Zest order #8016) and position it into<br />

the handpiece of a precision drilling device. Use the Bar Tap to chase and clean out the cast internal<br />

threads of the attachment site.<br />

6. A special Locator Gold-Plated Abutment Driver (contained in the Locator Core Tool, Zest order #8393)<br />

is designed to engage the inside diameter of the threaded Locator Bar Female and thread it into the bar.<br />

7. Final torque tightening of the Locator Bar Female to prevent screw loosening is achieved using the<br />

20Ncm Torque Wrench (Zest order #4391 Kit). In addition, Locator Torque Wrench Drivers that fit<br />

directly into the Locator Bar Female are available for most brands of torque wrenches.<br />

Technique to drill and tap a bar for a removable threaded Locator Bar Female<br />

1. A) Parts needed – New Case:<br />

(8589) Locator Bar Female (2.0mm Thread)<br />

(9102) 1.7mm Bar Drill (2.0mm Thread)<br />

(9104) 2.0mm Bar Tap (2.0mm Thread)<br />

Page of 8

(8016) Drill & Tap Holder<br />

B) Parts needed – Replace TSB Ball Attachment:<br />

(8587) Locator Bar Female (2-56 Thread)<br />

(9103) 1.8mm Bar Drill (2-56 Thread)<br />

(9105) 2-56 Bar Tap (2-56 Thread)<br />

(8016) Drill & Tap Holder<br />

2. The 1.7mm Bar Drill (Zest order #9102) and a 2.0mm Bar Tap (Zest order #9104) are used for creating<br />

the threaded site in a titanium bar or cast alloy bar. First use a round carbide bur to create a dimple into<br />

the top of the bar at the exact site of the planned preparation.<br />

3. Insert and tighten the 1.7mm Bar Drill into the Drill & Tap Holder (Zest order #8016) and position<br />

it into the handpiece of a precision drilling device. Use the 1.7mm Bar Drill to create the exact size<br />

diameter hole to a depth of 2.8mm that is needed for tapping the site.<br />

4. Place the 2.0mm Bar Tap into the Drill & Tap Holder and position it into the handpiece of a precision<br />

drilling device to create internal threads within the drilled site. The use of tapping fluid while cutting<br />

the threads is required to reduce the chance of breaking the tap off in the preparation.<br />

5. A special Locator Gold-Plated Abutment Driver (contained in the Locator Core Tool, Zest order #8393)<br />

is designed to engage the inside diameter of the threaded Locator Bar Female and thread it into the bar.<br />

6. Final torque tightening of the Locator Bar Female to prevent screw loosening is achieved using the<br />

20Ncm Torque Wrench (Zest order #4391 Kit). In addition, Locator Torque Wrench Drivers that fit<br />

directly into the Locator Bar Female are available for most brands of torque wrenches.<br />

Technique to laser weld a Locator Laser Bar Female on top of a bar<br />

1. A) Parts needed – Laser welding to a titanium bar:<br />

(8588) Locator Laser Bar Female (Titanium)<br />

(9107) Locator Paralleling Mandrel<br />

B) Parts needed – Laser welding to a cast gold alloy bar:<br />

(8590) Locator Laser Bar Female (Stainless Steel)<br />

(9107) Locator Paralleling Mandrel<br />

2. Use the Locator Paralleling Mandrel (Zest order #9107) in a surveyor to place the Laser Bar Female<br />

into position. Insert the split end of the Paralleling Mandrel into the socket of the Laser Bar Female and<br />

tighten the knurled set screw to spread the split portion of the mandrel that will secure the Laser Bar<br />

Female to the mandrel.<br />

3. Tack the Laser Bar Female into place on top of the bar by placing a spot of laser weld on opposite sides<br />

of the female.<br />

4. Remove the Paralleling Mandrel by loosening the knurled set screw. Form a bead of weld around the<br />

entire base circumference of the Laser Bar Female, welding the attachment to the top of the bar.<br />

5. Snap a Locator Yellow Bar Processing Cap Male (Zest order #8028 package) onto the welded Laser Bar<br />

Female to make sure the laser weld does not interfere with the seating of the Locator Denture Cap Male.<br />

Technique for casting-to a Locator Cast-To Bar Female into a gold alloy bar<br />

1. Parts needed – New Case:<br />

(8586) Locator Cast-To Bar Female<br />

(9107) Locator Paralleling Mandrel<br />

2. Use the Locator Paralleling Mandrel (Zest order #9107) in a surveyor to place the Cast-To Bar Female<br />

into the waxed bar in a position that is parallel with other Locator Bar attachments. Insert the split end<br />

of the Paralleling Mandrel into the socket of the Cast-To Bar Female and tighten the knurled set screw to<br />

spread the split portion of the mandrel that will secure the Cast-To Bar Female to the mandrel.<br />

Note: For accurate positioning of the Cast-To Bar Female the Locator Paralleling Mandrel is preferred<br />

to be used in place of the plastic Parallel Post that comes with the attachment, and is removed to use the<br />

Paralleling Mandrel instead.<br />

Page of 8

3. Wax the Cast-to Bar Female directly into the bar. The wax should be built up to the bottom outside<br />

corner on the base of the female, leaving the majority of the outer surface on the base above the top level<br />

of the bar.<br />

4. Remove the Paralleling Mandrel by loosening the knurled set screw, leaving the stainless steel<br />

attachment open for investment material to flow into.<br />

5. Spruing. Run the sprue at a 45 degree angle to the Cast-To Bar Female so the molten gold will flow<br />

down along one side of the female, around and up to the other side. The sprue should not be directed at<br />

the female that could possibly dislodge it when casting.<br />

6. It is recommended to use debubblizer to reduce surface tension during investing procedures.<br />

7. Investing. The most successful castings have been accomplished by using Ceramigold Investment by<br />

Whip Mix Corp. or an equivalent High Heat Investment. Use a casting ring at all times. (Do not use the<br />

ringless technique of investing and casting for the Cast-To Bar Female.)<br />

8. Mix a liquid/powder ratio of Ceramigold using 12ml to 60 grams of powder for each packet of mix<br />

needed. Hand mix for 15 seconds and vacuum mix for 90 seconds at 350-450 RPM. The investment<br />

material should be carefully painted into each attachment cavity to avoid trapping bubbles and to prevent<br />

gold from going inside the female. The remainder of the investment poured into the ring will stabilize<br />

the female during burnout. Place the ring in a water bath for one hour, then bench set for a half hour.<br />

9. Burnout. Place ring in a cold furnace (sprue side down) and raise the temperature to 1500° F maximum.<br />

Use a rate of climb of 0° F to 1500° F maximum over a time period of one hour. Hold at 1500° F<br />

maximum until burnout is complete. (Refer to investment manufacturer’s instructions for suggested<br />

burnout duration.)<br />

10. Casting. Use only precious or semi-precious alloys for casting the stainless steel female into a bar.<br />

Non-precious alloys should not be used. Cast the bar using recommended temperatures of the alloy<br />

manufacturer. The stainless steel Cast-To Bar Female will withstand a temperature of up to 2000° F<br />

without any dimensional change. Do not allow casting temperature to raise above 2000° F which will<br />

melt the stainless steel Bar Female!<br />

11. Divesting. After casting, allow the casting to bench cool for 20 minutes. Be careful to push out the<br />

casting and investment with proper tools. It is not recommended to hammer or bang on rings that may<br />

distort the castings. To remove the investment material from the Cast-To Bar Female without damage to<br />

the stainless steel, use an acid-free investment and porcelain remover solution in an ultrasonic unit for a<br />

period of 30-45 minutes. (Do not use a bur to remove the investment, sandblasting with aluminum<br />

oxide, or an acid pickling solution, all of which can damage the retention surfaces of the Bar<br />

Female attachment.) Clean the bar containing the Locator Cast-To attachment in an ultrasonic cleaner<br />

solution.<br />

12. Finishing and Polishing. When polishing with a rubber wheel, use caution not to damage the Cast-To<br />

Bar Female attachment. Polish the surface of the bar to make a smooth surface. The Locator Parallel<br />

Post (Zest order #8517) can be placed on the female to protect the attachment while polishing. [If<br />

additional polishing of the female attachment is required, it is recommended to only use glass beads at a<br />

low pressure (40 PSI) or a fiberglass or bristle polishing brush.]<br />

13. After polishing the bar, place a Locator Yellow Bar Processing Cap Male (Zest order #8028 package)<br />

onto each Cast-To Bar Female and check for proper fit. Clean again in an ultrasonic solution and deliver<br />

to the dental office.<br />

B. LOCATOR MALE PLACEMENT BY THE DENTIST<br />

1. Placement of the desired type of Locator Bar Female into the bar (see Section A) and delivery of the bar<br />

to the patient must be completed before beginning the procedure for placement of the Locator Male.<br />

2. Place a White Block-Out Spacer (Zest order #8519 Package) over the head of each Locator Bar Female.<br />

The spacer is used to block out the area immediately surrounding the attachment. The space created will<br />

allow the full resilient function of the pivoting metal denture cap over the Locator Male.<br />

Page of 8

NOTE: Due to the additional height required for the Laser Bar Females (Zest order #8588 and<br />

#8590), they require the use of 2 White Block-Out Spacers stacked on top of each other for proper<br />

block out. It is also necessary to block out all undercuts beneath the bar to prevent the added<br />

acrylic resin from locking the denture onto the bar.<br />

3. Insert a Locator Titanium Cap with Yellow Bar Processing Male (Zest order #8028 Package) onto each<br />

Locator Bar Female, leaving the White Block-Out Spacer beneath it. The Yellow Bar Processing Male<br />

will maintain the overdenture in the upper limit of its vertical resiliency during the processing procedure.<br />

4. Prepare a recess in the denture to accommodate the protruding Locator Denture Cap Male. There must<br />

be no contact between the denture and the titanium cap. If the denture rests on the metal cap, excess<br />

pressure on the implant will result.<br />

5. Use the Chairside Dental Attachment Light Cure Kit (Zest order #9403) to light cure bond the Locator<br />

Yellow Bar Denture Cap Male into the denture, or mix a permanent self-curing acrylic and place a small<br />

amount in the recess of the denture and around the metal cap of the Yellow Bar Processing Cap Male.<br />

6. Insert the denture into position in the oral cavity. Guide the patient into occlusion, maintaining a<br />

proper relationship with the opposing arch. Maintain the denture in a passive condition, without<br />

compression of the soft tissue, while the acrylic sets. Excessive occlusal pressure during the setting<br />

time may cause tissue recoil against the denture base and could contribute to dislodging and wear<br />

of the nylon males.<br />

7. After the acrylic resin has cured, remove the denture and discard the white spacer. Use a bur to remove<br />

excess acrylic, and polish the denture base before changing to the final resilient nylon male.<br />

8. Use the Locator Male Removal Tool (attached to the Locator Core Tool, Zest order #8393) to remove<br />

the Yellow Bar Processing Male from the metal denture cap. The sharp circular edge on the end of the<br />

removal tool should be wedged tightly down into the bottom of the Yellow Bar Processing Male so that<br />

it will catch the inside of the yellow plastic insert and pull it at an angle out of the metal housing.<br />

9. The Locator Male Seating Tool (contained in Locator Core Tool, Zest order #8393) is used to firmly<br />

push a Locator Replacement Male into the metal denture cap. The replacement male must seat securely<br />

into place, level with the rim of the cap. Use of multiple Locator attachments (3 or more) in the same<br />

dental arch may require use of the 3.0 lbs. (light retention) pink colored Replacement Male No. 8527,<br />

or 1.5 lbs. (extra light retention) blue colored Replacement Male No. 8529, for easier removal of the<br />

prosthesis by the patient.<br />

NOTE: The Replacement Male will not stay on the tool when it is turned upside down due to the<br />

varying sizes of males available. It is best to hold the denture with the base side down and snap the<br />

male into the metal denture cap.<br />

10. Instruct the patient in the path of insertion. Have the patient insert and remove the appliance several<br />

times.<br />

C. LOCATOR MALE PLACEMENT BY THE LABORATORY<br />

1. Placement of the desired type of Locator Bar Female into the bar must be completed (see Section A)<br />

before beginning the procedure for placement of the Locator Male.<br />

2. Place a Locator Impression Coping with Black Processing Male (Zest order #8505) onto each Locator<br />

Bar Female.<br />

3. Take an impression using a firm body impression material, exercising caution not to compress the<br />

soft tissue. The Locator Impression Coping is designed with minimum retention to be picked up with<br />

the impression material.<br />

4. Snap a Locator Female Analog (Zest order #8530) onto each Impression Coping in the impression. The<br />

analog female must not fall off when turned upside-down with vibration.<br />

5. Pour the master cast. Upon separation, the Locator Female Analog is a part of the master cast replicating<br />

the position of the Locator Bar Female on the bar.<br />

Page of 8

6. Before waxing and processing the appliance, place a Locator Cap with Yellow Bar Processing Male<br />

(Zest order #8028 package) onto each Female Analog in the master cast. Make sure the male is fully<br />

seated.<br />

7. Set the teeth and wax the appliance. Proceed with the processing technique of your choice through the<br />

boil-out step.<br />

8. After the boil-out, remove the Yellow Bar Processing Cap Male. Place a White Block-Out Spacer<br />

(Zest order #8028 package) over the head of each Female Analog. The spacer is used to block out the<br />

immediate area surrounding the Locator Bar Female. The space created will allow the full resilient<br />

function of the pivoting metal denture cap over the Locator Male.<br />

NOTE: Due to the additional height required for the Laser Bar Females (Zest order #8588 and<br />

#8590), they require the use of 2 White Block-Out Spacers stacked on top of each other for proper<br />

block out.<br />

9. Re-insert the Locator Yellow Bar Processing Cap Male onto each Female Analog, leaving the White<br />

Block-Out Spacer beneath it. The Yellow Bar Processing Male will maintain the overdenture in the<br />

upper limit of its vertical resiliency during the processing procedure.<br />

10. Complete the processing and discard the white spacer. Avoid damage to the final male by polishing the<br />

denture base before changing to the final resilient nylon male.<br />

11. Use the Locator Male Removal Tool (attached to the Locator Core Tool, Zest order #8393) to remove<br />

the Yellow Bar Processing Male from the metal denture cap. The sharp circular edge on the end of the<br />

removal tool should be wedged tightly down into the very bottom of the Yellow Bar Processing Male so<br />

that it will catch the inside of the yellow plastic insert and pull it at an angle out of the metal housing.<br />

12. The Locator Male Seating Tool (contained in Locator Core Tool, Zest order #8393) is used to firmly<br />

push a Locator Replacement Male into the empty metal denture cap. The replacement male must seat<br />

securely into place, level with the rim of the cap. Use of multiple Locator attachments (3 or more) in the<br />

same dental arch may require use of the 3.0 lbs. (light retention) pink colored Replacement Male No.<br />

8527, or 1.5 lbs. (extra light retention) blue colored Replacement Male No. 8529, for easier removal of<br />

the prosthesis by the patient.<br />

NOTE: The Replacement Male will not stay on the tool when it is turned upside down due to the<br />

varying sizes of males available. It is best to hold the denture with the base side down and snap the<br />

male into the metal denture cap.<br />

D. HOW TO CHANGE THE LOCATOR MALE<br />

1. The Locator Core Tool, (Zest order #8393) which contains a Locator Male Removal Tool and Locator<br />

Male Seating Tool is used to remove the nylon male from the metal denture cap and replace it with a<br />

Locator Replacement Male.<br />

2. Use the Male Removal Tool attached to the Locator Core Tool to remove the nylon male from the metal<br />

denture cap. The sharp circular edge on the end of the removal tool should be wedged tightly down into<br />

the very bottom of the resilient nylon male so that it will catch the inside of the plastic insert and pull it<br />

at an angle out of the metal housing. To discard the nylon male from the new tip on the Core Tool, point<br />

the tool down and away from you and tighten the new Male Removal Tool clockwise back onto the<br />

Core Tool. This will activate the removal pin and dislodge the nylon male from the tip end of the Male<br />

Removal Tool.<br />

3. The Male Seating Tool is used to firmly push a Locator Replacement Male into the empty metal denture<br />

cap. The replacement male must seat securely into place, level with the rim of the cap. Use of multiple<br />

Locator attachments (3 or more) in the same dental arch may require use of the 3.0 lbs. (light retention)<br />

pink colored Replacement Male No. 8527, or 1.5 lbs. (extra light retention) blue colored Replacement<br />

Male No. 8529, for easier removal of the prosthesis by the patient.<br />

NOTE: The Replacement Male will not stay on the tool when it is turned upside down due to the<br />

varying sizes of males available. It is best to hold the denture with the base side down and snap the<br />

male into the metal denture cap.<br />

Page of 8

E. RELINE AND REBASE<br />

1. Remove each existing nylon male from its metal denture cap following the steps in HOW TO CHANGE<br />

THE LOCATOR MALE (Section D). Replace them with Yellow Bar Processing Replacement Males<br />

(Zest order #8026). The built-in spacer of the Yellow Processing Male will maintain the overdenture in<br />

the same position on the bar as with the original processing, during the reline process.<br />

2. Take a reline impression using the existing overdenture as a tray.<br />

3. The Yellow Bar Processing Males will engage the Locator Bar Females and hold the prosthesis in place<br />

while the impression material sets. When the impression is withdrawn, the Yellow Bar Processing<br />

Replacement Males will remain in the metal denture caps.<br />

4. Snap a Locator Female Analog (Zest order #8530) into each Yellow Bar Processing Male in the<br />

impression and pour a master model.<br />

5. After processing the reline and polishing the denture base, replace the Yellow Bar Processing Males with<br />

the final resilient nylon Locator Replacement Males.<br />

F. PATIENT CARE<br />

Good oral hygiene is vital to implant bar success. The Locator Bar Females must be thoroughly cleaned<br />

daily. The use of a soft nylon bristle or end-tufted toothbrush to clean the attachment, and superfloss to<br />

keep the bar clean of plaque should be taught. A non-abrasive gel toothpaste, and an irrigation system is<br />

recommended to keep the socket of the Locator Bar Female clean.<br />

RETURN POLICY<br />

Check with your Distributor for their policy on returns.<br />

WARRANTY<br />

Zest Anchors, Inc. provides a limited warranty for its products, to the original purchaser, to be free from<br />

defects in workmanship and materials under normal use for a period of one year from the date of purchase.<br />

Zest Anchors, Inc. will, at its option, substitute the returned product that proves to be defective with a<br />

similar product, free of charge.<br />

Zest Anchors, Inc. continually strives to improve its products, and therefore, reserves the right to improve,<br />

modify or discontinue products and components at any time without notice or incurring obligation.<br />

Purchaser assumes all risks and liability resulting from the use of Zest Anchors, Inc. products, whether used<br />

separately or in combination with other products not of Zest Anchors, Inc. manufacture.<br />

ZEST ANCHORS, INC.<br />

2061 Wineridge Place / Escondido, CA 92029 USA<br />

EU AUTHORIZED REPRESENTATIVE<br />

VENTURA IMPLANT AND <strong>ATTACHMENT</strong> <strong>SYSTEM</strong>S<br />

69 The Avenue, Ealing, London, W13 8JR, England<br />

LOCATOR U.S. Patent No. 6,030,219 and 6,299,447.<br />

LOCATOR is a registered trademark of Zest Anchors, Inc.<br />

Illustrations by Ted Suggs<br />

L8003-TM REV D<br />

Page of 8