Studio PMC - Rio Grande

Studio PMC - Rio Grande

Studio PMC - Rio Grande

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Aluminum Contamination of Fine Silver<br />

By Tim McCreight<br />

Perhaps you've heard this warning: Don't<br />

allow any form of aluminum to touch<br />

your <strong>PMC</strong>! That's a bit overstated, but good<br />

advice in principle. This article will explain<br />

why you need to keep these metals apart.<br />

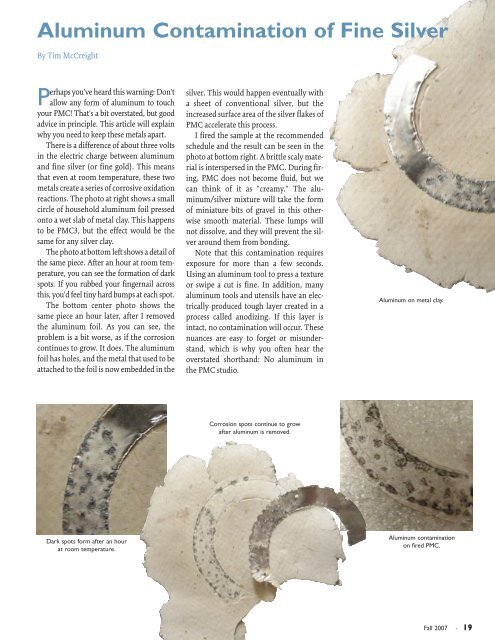

There is a difference of about three volts<br />

in the electric charge between aluminum<br />

and fine silver (or fine gold). This means<br />

that even at room temperature, these two<br />

metals create a series of corrosive oxidation<br />

reactions. The photo at right shows a small<br />

circle of household aluminum foil pressed<br />

onto a wet slab of metal clay. This happens<br />

to be <strong>PMC</strong>3, but the effect would be the<br />

same for any silver clay.<br />

The photo at bottom left shows a detail of<br />

the same piece. After an hour at room temperature,<br />

you can see the formation of dark<br />

spots. If you rubbed your fingernail across<br />

this, you'd feel tiny hard bumps at each spot.<br />

The bottom center photo shows the<br />

same piece an hour later, after I removed<br />

the aluminum foil. As you can see, the<br />

problem is a bit worse, as if the corrosion<br />

continues to grow. It does. The aluminum<br />

foil has holes, and the metal that used to be<br />

attached to the foil is now embedded in the<br />

silver. This would happen eventually with<br />

a sheet of conventional silver, but the<br />

increased surface area of the silver flakes of<br />

<strong>PMC</strong> accelerate this process.<br />

I fired the sample at the recommended<br />

schedule and the result can be seen in the<br />

photo at bottom right. A brittle scaly material<br />

is interspersed in the <strong>PMC</strong>. During firing,<br />

<strong>PMC</strong> does not become fluid, but we<br />

can think of it as "creamy." The aluminum/silver<br />

mixture will take the form<br />

of miniature bits of gravel in this otherwise<br />

smooth material. These lumps will<br />

not dissolve, and they will prevent the silver<br />

around them from bonding.<br />

Note that this contamination requires<br />

exposure for more than a few seconds.<br />

Using an aluminum tool to press a texture<br />

or swipe a cut is fine. In addition, many<br />

aluminum tools and utensils have an electrically<br />

produced tough layer created in a<br />

process called anodizing. If this layer is<br />

intact, no contamination will occur. These<br />

nuances are easy to forget or misunderstand,<br />

which is why you often hear the<br />

overstated shorthand: No aluminum in<br />

the <strong>PMC</strong> studio.<br />

Aluminum on metal clay.<br />

Corrosion spots continue to grow<br />

after aluminum is removed.<br />

Dark spots form after an hour<br />

at room temperature.<br />

Aluminum contamination<br />

on fired <strong>PMC</strong>.<br />

Fall 2007 · 19