Environmental Aspects of Phosphate and Potash Mining United ...

Environmental Aspects of Phosphate and Potash Mining United ...

Environmental Aspects of Phosphate and Potash Mining United ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong><br />

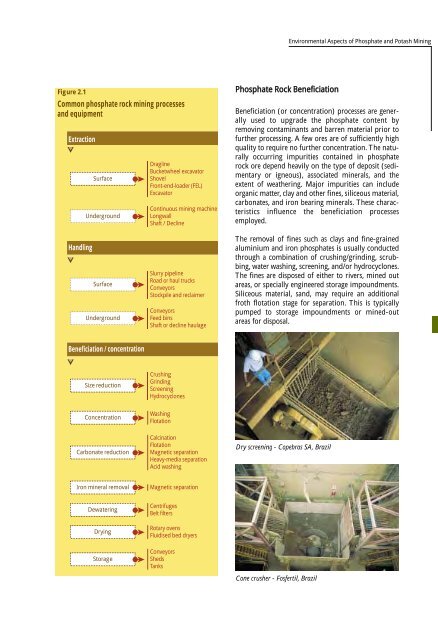

Figure 2.1<br />

Common phosphate rock mining processes<br />

<strong>and</strong> equipment<br />

Extraction<br />

Surface<br />

Underground<br />

Dragline<br />

Bucketwheel excavator<br />

Shovel<br />

Front-end-loader (FEL)<br />

Excavator<br />

Continuous mining machine<br />

Longwall<br />

Shaft / Decline<br />

<strong>Phosphate</strong> Rock Beneficiation<br />

Beneficiation (or concentration) processes are generally<br />

used to upgrade the phosphate content by<br />

removing contaminants <strong>and</strong> barren material prior to<br />

further processing. A few ores are <strong>of</strong> sufficiently high<br />

quality to require no further concentration. The naturally<br />

occurring impurities contained in phosphate<br />

rock ore depend heavily on the type <strong>of</strong> deposit (sedimentary<br />

or igneous), associated minerals, <strong>and</strong> the<br />

extent <strong>of</strong> weathering. Major impurities can include<br />

organic matter, clay <strong>and</strong> other fines, siliceous material,<br />

carbonates, <strong>and</strong> iron bearing minerals. These characteristics<br />

influence the beneficiation processes<br />

employed.<br />

H<strong>and</strong>ling<br />

Surface<br />

Underground<br />

Slurry pipeline<br />

Road or haul trucks<br />

Conveyors<br />

Stockpile <strong>and</strong> reclaimer<br />

Conveyors<br />

Feed bins<br />

Shaft or decline haulage<br />

The removal <strong>of</strong> fines such as clays <strong>and</strong> fine-grained<br />

aluminium <strong>and</strong> iron phosphates is usually conducted<br />

through a combination <strong>of</strong> crushing/grinding, scrubbing,<br />

water washing, screening, <strong>and</strong>/or hydrocyclones.<br />

The fines are disposed <strong>of</strong> either to rivers, mined out<br />

areas, or specially engineered storage impoundments.<br />

Siliceous material, s<strong>and</strong>, may require an additional<br />

froth flotation stage for separation. This is typically<br />

pumped to storage impoundments or mined-out<br />

areas for disposal.<br />

Beneficiation / concentration<br />

Size reduction<br />

Crushing<br />

Grinding<br />

Screening<br />

Hydrocyclones<br />

Concentration<br />

Washing<br />

Flotation<br />

Carbonate reduction<br />

Calcination<br />

Flotation<br />

Magnetic separation<br />

Heavy-media separation<br />

Acid washing<br />

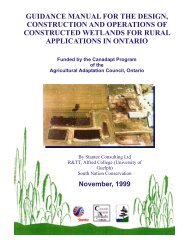

Dry screening - Copebras SA, Brazil<br />

Iron mineral removal<br />

Magnetic separation<br />

Dewatering<br />

Drying<br />

Centrifuges<br />

Belt filters<br />

Rotary ovens<br />

Fluidised bed dryers<br />

Storage<br />

Conveyors<br />

Sheds<br />

Tanks<br />

Cone crusher - Fosfertil, Brazil