Environmental Aspects of Phosphate and Potash Mining United ...

Environmental Aspects of Phosphate and Potash Mining United ...

Environmental Aspects of Phosphate and Potash Mining United ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong><br />

ways, during loading <strong>and</strong> unloading operations, at<br />

conveyor transfer points <strong>and</strong> during the stacking <strong>of</strong><br />

stockpiles <strong>and</strong> reclamation operations. Exhaust gases<br />

<strong>and</strong> particulates are largely produced by the operation<br />

<strong>of</strong> transport.<br />

A variety <strong>of</strong> dust control techniques are used, as discussed<br />

in Section 3.1.<br />

Equipment emissions are reduced by the use <strong>of</strong><br />

exhaust filters, regular equipment maintenance programs<br />

<strong>and</strong> replacing old engines with new, more<br />

efficient <strong>and</strong> cleaner models.<br />

Watershed Protection<br />

Regulations in Florida to protect watersheds from disturbance<br />

have restricted the development <strong>of</strong><br />

floodplains, streams <strong>and</strong> rivers. Accordingly, phosphate<br />

rock mining operations must establish buffer<br />

zones <strong>and</strong> work around these features. However, on<br />

occasions crossings may have to be constructed<br />

across them to facilitate access to mining areas.<br />

Development <strong>of</strong> a new mining area at the IMC<br />

<strong>Phosphate</strong> Four Corners operation in central Florida<br />

required the construction <strong>of</strong> a river crossing. This was<br />

designed to allow vehicle <strong>and</strong> equipment access <strong>and</strong><br />

the passage <strong>of</strong> several large diameter slurry pipelines<br />

between the mining area <strong>and</strong> the beneficiation plant.<br />

The design has a number <strong>of</strong> features to mitigate<br />

potential environmental impacts.<br />

Culverts have been placed under the earthen vehicle<br />

crossing, allowing normal river flow to be maintained.<br />

Silt traps contain minor erosion sediments from the<br />

crossing.<br />

During heavy rain, the water level rises <strong>and</strong> passes<br />

over the crossing. Surfacing the vehicle roadway with<br />

coarse aggregate <strong>and</strong> the planting <strong>of</strong> grass on adjacent<br />

roadside areas has reduced the potential for<br />

erosion.<br />

The large-diameter ore slurry pipelines have been<br />

placed alongside the crossing roadway <strong>and</strong> elevated<br />

to allow water to pass underneath. In the event <strong>of</strong> failure,<br />

the pipes are double lined at the crossing,<br />

discharging to a containment pond at one end, while<br />

an automated monitoring system alerts management.<br />

Watershed protection is an integral part <strong>of</strong> the crossing<br />

design. The construction <strong>of</strong> a stable, non-eroding<br />

river crossing <strong>and</strong> the installation <strong>of</strong> a monitoring <strong>and</strong><br />

containment system in the event <strong>of</strong> a slurry pipeline<br />

failure prevent contamination <strong>of</strong> downstream areas.<br />

Transport <strong>of</strong> Ore <strong>and</strong> Concentrate by Slurry<br />

Pipeline<br />

The transport <strong>of</strong> ore <strong>and</strong> concentrates as a slurry (a<br />

mixture <strong>of</strong> water <strong>and</strong> ore particles in suspension) has<br />

benefits such as less road transport congestion,<br />

reduced vehicle exhaust emissions <strong>and</strong> the elimination<br />

<strong>of</strong> sources <strong>of</strong> dust emission. Slurry pipelines are<br />

used at a number <strong>of</strong> operations worldwide.<br />

In Florida, the phosphate mining operations <strong>of</strong> companies<br />

such as Cargill Fertilizer Inc. <strong>and</strong> IMC<br />

<strong>Phosphate</strong> use high-pressure water jets to convert the<br />

ore excavated by the draglines into a slurry which can<br />

be pumped to the beneficiation plants through large<br />

diameter pipelines.<br />

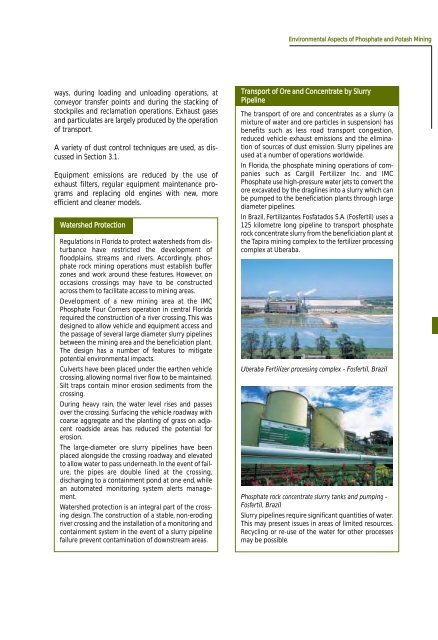

In Brazil, Fertilizantes Fosfatados S.A. (Fosfertil) uses a<br />

125 kilometre long pipeline to transport phosphate<br />

rock concentrate slurry from the beneficiation plant at<br />

the Tapira mining complex to the fertilizer processing<br />

complex at Uberaba.<br />

Uberaba Fertilizer processing complex - Fosfertil, Brazil<br />

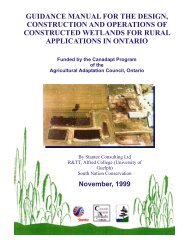

<strong>Phosphate</strong> rock concentrate slurry tanks <strong>and</strong> pumping -<br />

Fosfertil, Brazil<br />

Slurry pipelines require significant quantities <strong>of</strong> water.<br />

This may present issues in areas <strong>of</strong> limited resources.<br />

Recycling or re-use <strong>of</strong> the water for other processes<br />

may be possible.