Environmental Aspects of Phosphate and Potash Mining United ...

Environmental Aspects of Phosphate and Potash Mining United ...

Environmental Aspects of Phosphate and Potash Mining United ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong><br />

Beneficiation plants frequently implement measures<br />

to contain <strong>and</strong> recover process spillages, in order to<br />

minimize environmental effects <strong>and</strong> product loss.<br />

Water Consumption<br />

Beneficiation operations generally consume large<br />

quantities <strong>of</strong> fresh water for processes such as washing<br />

<strong>and</strong> flotation. The water is usually sourced from nearby<br />

surface <strong>and</strong> ground water supplies. In arid areas,<br />

local water supplies may be limited, requiring water to<br />

be piped considerable distances.<br />

Water piped in from distant sources may provide a<br />

suitable source for other users.<br />

Provision <strong>of</strong> Water Resources to Other Users<br />

In New Mexico, the Mississippi Chemical Corporation<br />

pipes water from a distant freshwater aquifer to their<br />

Carlsbad potash operation. Local groundwater in the<br />

vicinity <strong>of</strong> the operation is high in total dissolved<br />

solids <strong>and</strong> not suitable for human or livestock consumption.<br />

The freshwater pipeline has provided a<br />

water source available for local ranchers, reducing<br />

reliance on variable rainfall in this arid area.<br />

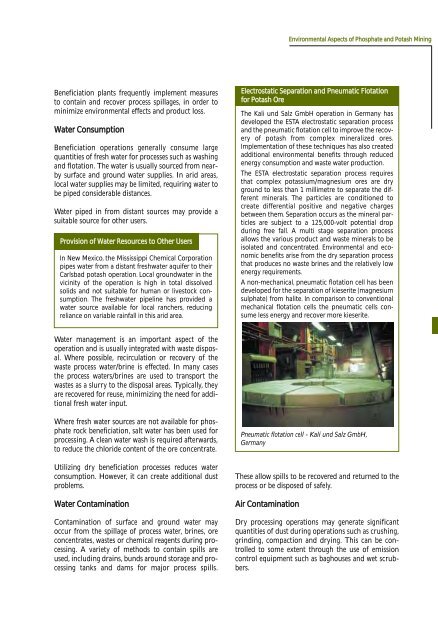

Electrostatic Separation <strong>and</strong> Pneumatic Flotation<br />

for <strong>Potash</strong> Ore<br />

The Kali und Salz GmbH operation in Germany has<br />

developed the ESTA electrostatic separation process<br />

<strong>and</strong> the pneumatic flotation cell to improve the recovery<br />

<strong>of</strong> potash from complex mineralized ores.<br />

Implementation <strong>of</strong> these techniques has also created<br />

additional environmental benefits through reduced<br />

energy consumption <strong>and</strong> waste water production.<br />

The ESTA electrostatic separation process requires<br />

that complex potassium/magnesium ores are dry<br />

ground to less than 1 millimetre to separate the different<br />

minerals. The particles are conditioned to<br />

create differential positive <strong>and</strong> negative charges<br />

between them. Separation occurs as the mineral particles<br />

are subject to a 125,000-volt potential drop<br />

during free fall. A multi stage separation process<br />

allows the various product <strong>and</strong> waste minerals to be<br />

isolated <strong>and</strong> concentrated. <strong>Environmental</strong> <strong>and</strong> economic<br />

benefits arise from the dry separation process<br />

that produces no waste brines <strong>and</strong> the relatively low<br />

energy requirements.<br />

A non-mechanical, pneumatic flotation cell has been<br />

developed for the separation <strong>of</strong> kieserite (magnesium<br />

sulphate) from halite. In comparison to conventional<br />

mechanical flotation cells the pneumatic cells consume<br />

less energy <strong>and</strong> recover more kieserite.<br />

Water management is an important aspect <strong>of</strong> the<br />

operation <strong>and</strong> is usually integrated with waste disposal.<br />

Where possible, recirculation or recovery <strong>of</strong> the<br />

waste process water/brine is effected. In many cases<br />

the process waters/brines are used to transport the<br />

wastes as a slurry to the disposal areas. Typically, they<br />

are recovered for reuse, minimizing the need for additional<br />

fresh water input.<br />

Where fresh water sources are not available for phosphate<br />

rock beneficiation, salt water has been used for<br />

processing. A clean water wash is required afterwards,<br />

to reduce the chloride content <strong>of</strong> the ore concentrate.<br />

Utilizing dry beneficiation processes reduces water<br />

consumption. However, it can create additional dust<br />

problems.<br />

Water Contamination<br />

Contamination <strong>of</strong> surface <strong>and</strong> ground water may<br />

occur from the spillage <strong>of</strong> process water, brines, ore<br />

concentrates, wastes or chemical reagents during processing.<br />

A variety <strong>of</strong> methods to contain spills are<br />

used, including drains, bunds around storage <strong>and</strong> processing<br />

tanks <strong>and</strong> dams for major process spills.<br />

Pneumatic flotation cell - Kali und Salz GmbH,<br />

Germany<br />

These allow spills to be recovered <strong>and</strong> returned to the<br />

process or be disposed <strong>of</strong> safely.<br />

Air Contamination<br />

Dry processing operations may generate significant<br />

quantities <strong>of</strong> dust during operations such as crushing,<br />

grinding, compaction <strong>and</strong> drying. This can be controlled<br />

to some extent through the use <strong>of</strong> emission<br />

control equipment such as baghouses <strong>and</strong> wet scrubbers.