How To Rebuild Your Small-Block Ford.pdf - Index of

How To Rebuild Your Small-Block Ford.pdf - Index of

How To Rebuild Your Small-Block Ford.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

You'll find the crankshaft casting number on<br />

the side <strong>of</strong> the front throw. 2M indicates this<br />

is a 302 crankshaft.<br />

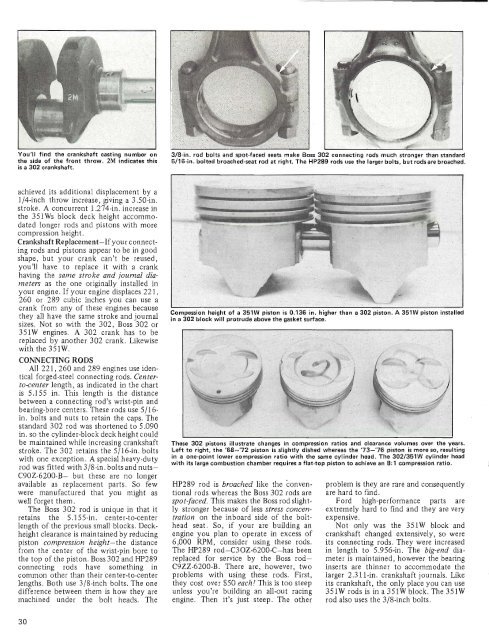

318-in. rod bolts and spot-faced seats make Boss 302 connecting rods much stronger than standard<br />

5116-in. bolted broached-seat rod at right. The HP289 rods use the larger bolts, but rodsare broached.<br />

achieved its additional displacement by a<br />

114-inch throw increase, giving a 3 .SO-in.<br />

stroke. A concurrent 1.274-in. increase in<br />

the 351Ws block deck height accommodated<br />

longer rods and pistons with more<br />

compression height.<br />

Crankshaft Replacement-If your connecting<br />

rods and pistons appear to be in good<br />

shape, but your crank can't be reused,<br />

you'll have to replace it with a crank<br />

having the same stroke and journal diameters<br />

as the one originally installed in<br />

your engine. If your engine displaces 221,<br />

260 or 289 cubic inches you can use a<br />

crank from any <strong>of</strong> these engines because<br />

Compession height <strong>of</strong> a 351W piston is 0.136 in. higher than a 302 piston. A 351W piston installed<br />

they have the same stroke and journal in a 302 block will protrude above the gasket surface.<br />

sizes. Not so with the 302. Boss 302 or<br />

351W engines. A 302 crank has to be<br />

replaced by another 302 crank. Likewise<br />

with the 351W.<br />

CONNECTING RODS<br />

All 221,260 and 289 engines use identical<br />

forged-steel connecting rods. Centerto-center<br />

length, as indicated in the chart<br />

is 5.1 55 in. This length is the distance<br />

between a connecting rod's wrist-pin and<br />

bearing-bore centers. These rods use 511 6-<br />

in. bolts and nuts to retain the caps. The<br />

standard 302 rod was shortened to 5.090<br />

in. so the cylinder-block deck height could<br />

be maintained while increasing crankshaft<br />

stroke. The 302 retains the 5116-in. bolts<br />

with one exception. A special heavy-duty<br />

rod was fitted with 318-in. bolts and nuts-<br />

C90Z-6200-B- but these are no longer<br />

available as replacement parts. So few<br />

were manufactured that you might as<br />

well forget them.<br />

The Boss 302 rod is unique in that it<br />

retains the 5.155-in. center-to-center<br />

length <strong>of</strong> the previous small blocks. Deckheight<br />

clearance is maintained by reducing<br />

piston compression height-the distance<br />

from the center <strong>of</strong> the wrist-pin bore to<br />

the top <strong>of</strong> the piston. Boss 302 and HP289<br />

connecting rods have something in<br />

common other than their center-to-center<br />

lengths. Both use 318-inch bolts. The one<br />

difference between them is how they are<br />

machined under the bolt heads. The<br />

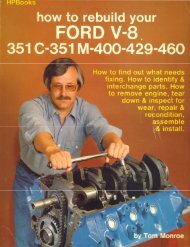

These 302 pistons illustrate changes in compression ratios and clearance volumes over the years.<br />

Left to right, the '68-'72 piston is slightly dished whereas the '73-'76 piston is more so, resulting<br />

in a one-point lower compression ratio with the same cylinder head. The 3021351W cylinder head<br />

with its large combustion chamber requires a flat-top piston to achieve an 8:1 compression ratio.<br />

HP289 rod is broached like the conventional<br />

rods whereas the Boss 302 rods are<br />

spot-faced. This makes the Boss rod slightly<br />

stronger because <strong>of</strong> less stress concentration<br />

on the inboard side <strong>of</strong> the bolthead<br />

seat. So, if your are building an<br />

engine you plan to operate in excess <strong>of</strong><br />

6,000 RPM, consider using these rods.<br />

The HP289 rod-C30Z-6200-C-has been<br />

replaced for service by the Boss rod-<br />

C9ZZ-6200-B. There are, however, two<br />

problems with using these rods. First,<br />

they cost over $50 each! This is too steep<br />

unless you're building an all-out racing<br />

engine. Then it's just steep. The other<br />

problem is they are rare and consequently<br />

are hard to find.<br />

<strong>Ford</strong> hgh-performance parts are<br />

extremely hard to find and they are very<br />

expensive.<br />

Not only was the 351W block and<br />

crankshaft changed extensively, so were<br />

its connecting rods. They were increased<br />

in length to 5.956-in. The big-end diameter<br />

is maintained, however the bearing<br />

inserts are thinner to accommodate the<br />

larger 2.3 1 1-in. crankshaft journals. Like<br />

its crankshaft, the only place you can use<br />

351W rods is in a 351W block. The 351W<br />

rod also uses the 318-inch bolts.