How To Rebuild Your Small-Block Ford.pdf - Index of

How To Rebuild Your Small-Block Ford.pdf - Index of

How To Rebuild Your Small-Block Ford.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

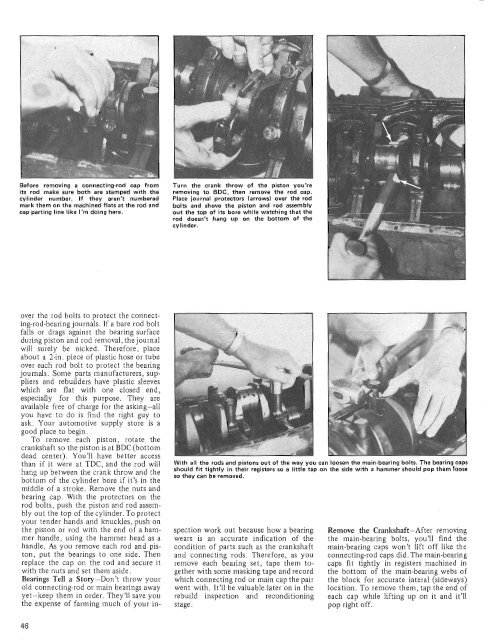

Before removing a connecting-rod cap from<br />

its rod make sure both are stamped with the<br />

Turn the crank throw <strong>of</strong> the piston you're<br />

removing to BDC. then remove the rod cap.<br />

cylinder number. If they aren't numbered Place joirnal protectors (arrows) over the rod<br />

mark them on the machined flats at the rod and bolts and shove the piston and rod assembly<br />

cap parting line like I'm doing here.<br />

out the top <strong>of</strong> its bore while watching that the<br />

rod doesn't hang up on the bottom <strong>of</strong> the<br />

cylinder.<br />

r<br />

especially for this purpose. They are<br />

available free <strong>of</strong> charge for the asking-all<br />

you have to do is find the right guy to -<br />

ask. <strong>Your</strong> automotive supply .--<br />

store is a<br />

good place to begin.<br />

<strong>To</strong> remove each piston, rotate the<br />

crankshaft so the piston is at BDC (bottom<br />

dead than if center). it were You'll at TDc, have and better the rod access will<br />

hang up between the crank throw and the<br />

bottom <strong>of</strong> the cylinder bore if it's in the<br />

middle <strong>of</strong> a stroke. Remove the nuts and<br />

bearing cap. With the protectors on the<br />

rod bolts, push the piston and rod assembly<br />

out the top <strong>of</strong> the cylinder. <strong>To</strong> protect<br />

your tender hands and knuckles, push on<br />

the piston or rod with the end <strong>of</strong> a hammer<br />

handle, using the hammer head as a<br />

handle. As you remove each rod and piston,<br />

put the bearings to one side. Then<br />

replace the cap on the rod and secure it<br />

with. the nuts and set them aside.<br />

Bearings Tell a Story-Don't throw your<br />

old connecting-rod or main bearings away<br />

yet-keep them in order. They'll save you<br />

the expense <strong>of</strong> farming much <strong>of</strong> your in-<br />

y<br />

With Iall the rods and pistons out <strong>of</strong> the way you can loosen the main-bearing bolts. The bearing caps<br />

should fit tightly in their registers so a little tap on the side with a hammer should pop them loose<br />

so they can be removed.<br />

spection work out because how a bearing<br />

wears is an accurate indication <strong>of</strong> the<br />

condition <strong>of</strong> parts such as the crankshaft<br />

and connecting rods. Therefore, as you<br />

remove each bearing set, tape them together<br />

with some masking tape and record<br />

which connecting rod or main cap the pair<br />

went with. It'll be valuable later on in the<br />

rebuild inspection and reconditioning<br />

stage.<br />

Remove the Crankshaft-After removing<br />

the main-bearing bolts, you'll find the<br />

main-bearing caps won't lift <strong>of</strong>f like the<br />

connecting-rod caps did. The main-bearing<br />

caps fit tightly in registers machined in<br />

the bottom <strong>of</strong> the main-bearing webs <strong>of</strong><br />

the block for accurate lateral (sideways)<br />

location. <strong>To</strong> remove them, tap the end <strong>of</strong><br />

each cap while lifting up on it and it'll<br />

pop right <strong>of</strong>f.