How To Rebuild Your Small-Block Ford.pdf - Index of

How To Rebuild Your Small-Block Ford.pdf - Index of

How To Rebuild Your Small-Block Ford.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1 c.<br />

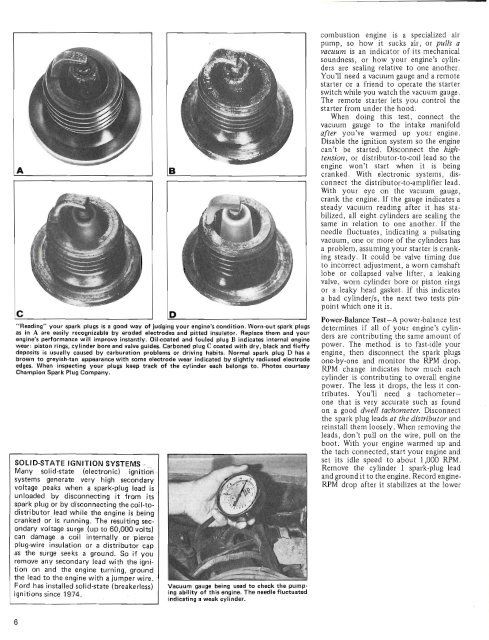

"Reading" your spark plugs is a good way. <strong>of</strong> judging your engine's condition. Worn-out spark plugs<br />

as in A are easily recognizable by eroded electrodes and pitted insulator. Replace them and your<br />

engine's performance will improve instantly. Oil-coated and fouled plug B indicates internal engine<br />

wear: piston rings, cylinder bore and valve guides. Carboned plug C coated with dry, black and fluffy<br />

deposits is usually caused by carburetion problems or driving habits. Normal spark plug D has a<br />

brown to greyish-tan appearance with some electrode wear indicated by slightly radiused electrode<br />

edges. When inspecting your plugs keep track <strong>of</strong> the cylinder each belongs to. Photos courtesy<br />

Champion Spark Plug Company.<br />

SOLID-STATE IGNfTlON SYSTEMS .<br />

Many solid-state (electronic) ignition<br />

systems generate very high secondary<br />

voltage peaks when a spark-plug lead is<br />

unloaded by disconnecting it from its<br />

spark plug or by disconnecting the coil-todistributor<br />

lead while the engine is being<br />

cranked or is running. The resulting secondary<br />

voltage surge (up to 60,000 volts)<br />

can damage a coil internallv or ~ krce 1<br />

plug-wire insulation or a distributor cap<br />

as the surge seeks a ground. So if you<br />

remove any secondary lead with the ignition<br />

on and the engine turning, ground<br />

the lead to the engine with a jumper wire.<br />

<strong>Ford</strong> has installed solid-state (breakerless)<br />

ignitions since 1974.<br />

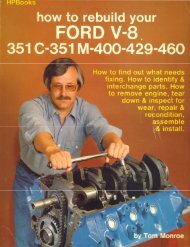

Vacuum gauge being used to check the pumping<br />

ability <strong>of</strong> this engine. The needle fluctuated<br />

indicating a weak cylinder.<br />

combustion engine is a specialized air<br />

pump, so how it sucks air, or pulls a<br />

vacuum is an indicator <strong>of</strong> its mechanical<br />

soundness, or how your engine's cylinders<br />

are sealing relative to one another.<br />

You'll need a vacuum gauge and a remote<br />

starter or a friend to operate the starter<br />

switch while you watch the vacuum gauge.<br />

The remote starter lets you control the<br />

starter from under the hood.<br />

When doing this test, connect the<br />

vacuum gauge to the intake manifold<br />

after you've warmed up your engine.<br />

Disable the ignition system so the engine<br />

can't be started. Disconnect the hightension,<br />

or distributor-to-coil lead so the<br />

engine won't start when it is being<br />

cranked. With electronic systems, disconnect<br />

the distributor-to-amplifier lead.<br />

With your eye on the vacuum gauge,<br />

crank the engine. If the gauge indicates a<br />

steady vacuum reading after it has stabilized,<br />

all eight cylinders are sealing the<br />

same in relation to one another. If the<br />

needle fluctuates, indicating a pulsating<br />

vacuum, one or more <strong>of</strong> the cylinders has<br />

a problem, assuming your starter is cranking<br />

steady. It could be valve timing due<br />

to incorrect adjustment, a worn camshaft<br />

lobe or collapsed valve lifter, a leaking<br />

valve, worn cylinder bore or piston rings<br />

or a leaky head gasket. If this indicates<br />

a bad cylinder/s, the next two tests pinpoint<br />

which one it is.<br />

Power-Balance Test-A power-balance test<br />

determines if all <strong>of</strong> your engine's cylinders<br />

are contributing the same amount <strong>of</strong><br />

power. The method is to fast-idle your<br />

engine, then disconnect the spark plugs<br />

one-by-one and monitor the RPM drop.<br />

RPM change indicates how much each<br />

cylinder is contributing to overall engine<br />

power. The less it drops, the less it contributes.<br />

You'll need a tachometerone<br />

that is very accurate such as found<br />

on a good dwell tachometer. Disconnect<br />

the spark plug leads at the distributor and<br />

reinstall them loosely. When removing the<br />

leads, don't pull on the wire, pull on the<br />

boot. With your engine warmed up and<br />

the tach connected, start your engine and<br />

set its idle speed to about 1,000 RPM.<br />

Remove the cylinder 1 spark-plug lead<br />

and ground it to the engine. Record engine-<br />

RPM drop after it stabilizes at the lower