How To Rebuild Your Small-Block Ford.pdf - Index of

How To Rebuild Your Small-Block Ford.pdf - Index of

How To Rebuild Your Small-Block Ford.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

get into expensive trouble. For instance,<br />

crankshaft throw, connecting-rod centerto-center<br />

length, piston compression<br />

height and deck-height clearance must be<br />

compatible with the block's deck height.<br />

For a given stroke crankshaft, a longer<br />

rod will cause a given piston to operate<br />

higher in its bore. Installing a shorter connecting<br />

rod causes the same piston to<br />

operate lower in the same bore with the<br />

same crankshaft. This also applies to piston<br />

compression height. As compression<br />

height is increased-the wrist-pin bore is<br />

moved down in relation to the piston topthe<br />

top <strong>of</strong> the piston will operate higher<br />

in the cylinder bore. Reducing compression<br />

height moves it down. The last item,<br />

deck-height clearance, is simply how far<br />

short a piston at TDC is from coming<br />

even with a block's deck or gasket surface.<br />

This clearance is necessary to prevent a<br />

piston from hitting the cylinder head.<br />

The question now becomes, "<strong>How</strong> does<br />

all this relate to swapping parts"<br />

The sum <strong>of</strong> the crankshaft throw,<br />

connecting-rod length, piston compression<br />

height and deck-height clearance must<br />

not exceed a block's deck height, otherwise<br />

serious engine damage will result.<br />

This is particularly true if it is exceeded<br />

by more than the specified deck-height<br />

clearance. In this case the piston will<br />

come higher than the deck surface and<br />

impact against the cylinder head. On the<br />

other hand, if this sum is less, you'll have<br />

a very underpowered engine because its<br />

compression ratio will be low.<br />

There are also other limitations to consider<br />

when swapping bottom-end components.<br />

A 302 crankshaft cannot be<br />

installed in a 221 even though the numbers<br />

add up right: the bottom <strong>of</strong> the 221<br />

pistons will hit the connecting rods. 221<br />

pistons are the only ones that can possibly<br />

work because <strong>of</strong> the 221s bore size.<br />

Oddly enough a similar situation exists<br />

with the 289 even though the 302 and<br />

289 bores and piston compression heights<br />

are the same. 289 piston skirts will hit a<br />

302s crankshaft counterbalances because<br />

289 piston skirts are longer than a 302s.<br />

Consequently, 302 rods and pistons must<br />

be used when installing a 302 crank in a<br />

289 block. This interchange <strong>of</strong> parts<br />

makes a 302 out <strong>of</strong> a 289. Since 1978,<br />

<strong>Ford</strong> service pistons for the 289-2V and<br />

'68-'72 302s are interchangeable.<br />

One final and vital factor you must<br />

consider when changing bottom-end<br />

components is balance. Pistons, connecting<br />

rods, crankshaft and crankshaft<br />

damper and flywheel are matched for<br />

proper engine balance. Consequently, to<br />

ensure you'll end up with a balanced<br />

engine, particularly if the crankshaft and<br />

rods are changed, the complete assembly<br />

should be checked for balance. Many<br />

engine machine shops are equipped to do<br />

this.<br />

CYLINDER HEADS<br />

Cylinder-head interchangeability gets<br />

very confusing, but not because the heads<br />

are so different-except for the Boss 302<br />

heads which are radically different from<br />

all the others. Detail changes made to the<br />

heads over the years prevent interchanging<br />

heads in many instances. Another factor<br />

contributing to the cylinder-head-complexity<br />

problem is government emission<br />

standards and the design changes which<br />

have been made to meet these standards.<br />

All small-block heads will bolt on all smallblock<br />

engines, but this does not mean<br />

they'll all work. Some will and some won't.<br />

Cylinder-head Basics-<strong>To</strong> interchange<br />

cylinder heads you'll have to understand<br />

some cylinder-head basics. Let's start<br />

with compression ratio and how it is figured.<br />

As a cylinder's piston travels from<br />

BDC to TDC it sweeps through or displaces<br />

a volume called swept volume<br />

(S.V.) With the piston at TDC, the volume<br />

above it is called clearance volunze (C.V.).<br />

Clearance volume includes the combustion-chamber<br />

volume in the cylinder head,<br />

volume created by the head gasket spacing<br />

the head above the block deck surface,<br />

additional volume created by piston deckheight<br />

clearance and the shape <strong>of</strong> the piston<br />

top. A concave or dished piston adds<br />

to the clearance volume. A convex or popup<br />

piston will reduce it. Of these four<br />

factors, cylinder-head combustion-charnber<br />

volume is the biggest contributor to<br />

an engine's clearance volume.<br />

A cylinder's compression ratio is directly<br />

proportional to its clearance volume<br />

and its swept volume or displacement:<br />

Compression Ratio<br />

- Swept Volume +<br />

Clearance Volume<br />

CRANKSHAF<br />

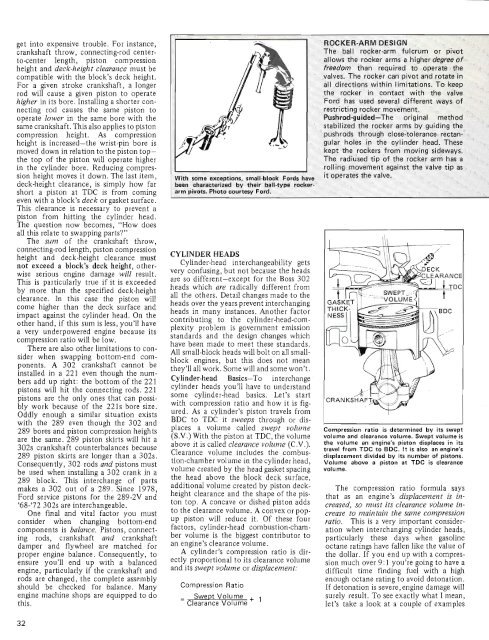

Compression ratio is determined by its swept<br />

volume and clearance volume. Swept volume is<br />

the volume an engine's piston displaces in its<br />

travel from TDC to BDC. It is also an engine's<br />

displacement divided by its number <strong>of</strong> pistons.<br />

Volume above a piston at TDC is clearanoe<br />

volume.<br />

The compression ratio formula says<br />

that as an engine's displacement is increased,<br />

so must its clearance volume increase<br />

to maintain the same compression<br />

ratio. This is a very important consideration<br />

when interchanging cylinder heads,<br />

particularly these days when gasoline<br />

octane ratings have fallen like the value <strong>of</strong><br />

the dollar. If you end up with a compression<br />

much over 9: 1 you're going to have a<br />

difficult time finding fuel with a high<br />

enough octane rating to avoid detonation.<br />

If detonation is severe, engine damage will<br />

surely result. <strong>To</strong> see exactly what I mean,<br />

let's take a look at a couple <strong>of</strong> examples