Bravo Transom Assembly Specifications

Bravo Transom Assembly Specifications

Bravo Transom Assembly Specifications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

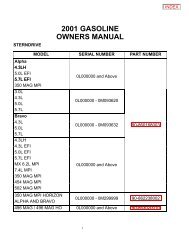

SERVICE MANUAL NUMBER 11<br />

Cleaning and Inspection<br />

Installation<br />

SERVICE PROCEDURES REQUIRING MINOR DISASSEMBLY<br />

1. Inspect exhaust bellows for internal charring, cracks, cuts or hardening.<br />

2. Clean old adhesive from bellows mounting flange on gimbal housing and on bell housing<br />

with lacquer thinner.<br />

3. Clean old adhesive from mounting surface of exhaust bellows if using old bellows.<br />

4. Roughen exhaust bellows mating surfaces with sandpaper and wipe clean with lacquer<br />

thinner.<br />

WARNING<br />

Be sure to follow label directions when using bellows adhesive.<br />

1. Apply bellows adhesive to mounting surfaces on inside of bellows. Allow adhesive to dry<br />

until no longer tacky, (approximately 10 min.).<br />

CAUTION<br />

Bellows clamps may corrode if grounding clips are not installed.<br />

2. Position grounding clips on bellows.<br />

b<br />

a<br />

a<br />

c<br />

22079<br />

a - Apply Bellows Adhesive<br />

b - Grounding Clips<br />

c - Part Number - all replacement bellows should be P/N 18654. Do not use earlier model bellows.<br />

3. Install exhaust bellows on gimbal housing. Torque to 35 lb. in. (4 N·m).<br />

b<br />

a<br />

a - Exhaust Bellows<br />

b - Hose Clamp<br />

75964<br />

90-17431--4 MARCH 1998 Page 4A-29