Service Manual Number 11 Removal Installation And Adjustments

Service Manual Number 11 Removal Installation And Adjustments

Service Manual Number 11 Removal Installation And Adjustments

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

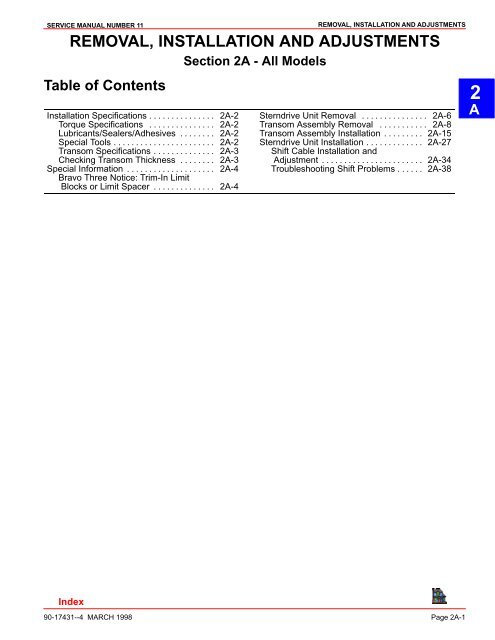

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTSREMOVAL, INSTALLATION AND ADJUSTMENTSSection 2A - All ModelsTable of Contents<strong>Installation</strong> Specifications . . . . . . . . . . . . . . . 2A-2Torque Specifications . . . . . . . . . . . . . . . 2A-2Lubricants/Sealers/Adhesives . . . . . . . . 2A-2Special Tools . . . . . . . . . . . . . . . . . . . . . . . 2A-2Transom Specifications . . . . . . . . . . . . . . 2A-3Checking Transom Thickness . . . . . . . . 2A-3Special Information . . . . . . . . . . . . . . . . . . . . 2A-4Bravo Three Notice: Trim-In LimitBlocks or Limit Spacer . . . . . . . . . . . . . . 2A-4Sterndrive Unit <strong>Removal</strong> . . . . . . . . . . . . . . . 2A-6Transom Assembly <strong>Removal</strong> . . . . . . . . . . . 2A-8Transom Assembly <strong>Installation</strong> . . . . . . . . . 2A-15Sterndrive Unit <strong>Installation</strong> . . . . . . . . . . . . . 2A-27Shift Cable <strong>Installation</strong> andAdjustment . . . . . . . . . . . . . . . . . . . . . . . 2A-34Troubleshooting Shift Problems . . . . . . 2A-382A90-17431--4 MARCH 1998 Page 2A-1

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong><strong>Installation</strong> SpecificationsTorque SpecificationsNOTE: Securely tighten all fasteners not listed below.DESCRIPTIONTORQUElb. in. lb. ft. N⋅mExhaust Pipe to Gimbal Housing Screws 23 31Propeller Nut 1 55 75Tighten Nut Until ItDrive Unit Shift Cable LocknutBottoms Out Against Flat Washer, thenLoosen 1 TurnSteering Cable Coupler Nut 35 48Steering system Pivot Bolts 50 68Transom Assembly Attaching Screws andNuts23 31Power Steering Hydraulic Hose Fittings 23 31Sterndrive Unit to Bell Housing AttachingNuts50 681 : Amount specified is MINIMUM.Lubricants/Sealers/AdhesivesSpecial ToolsDESCRIPTIONPART NUMBERQuicksilver 2-4-C Marine Lubricant withTeflon92-825407A12Quicksilver Special Lubricant 101 92-13872A1Perfect Seal 92-34227-1Liquid Neoprene 92-257<strong>11</strong>--2Quicksilver Anti-Corrosion Grease 92-78376A6Quicksilver Engine Coupler Spline Grease 92-816391A4DESCRIPTIONPART NUMBERShift Cable Adjustment Tool 91-12427Engine Alignment Tool Assembly 91-805475A1Page 2A-2 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>Transom SpecificationsREMOVAL, INSTALLATION AND ADJUSTMENTSaaecdbbf22170a - Transom Thickness - 2 - 2-1/4 in. (51mm-57mm)b - Transom Surfaces - Parallel to within 1/8 in. (3 mm)c - Area Covered by Inner Transom Plate - Flat to within1/8 in. (3.2 mm)d - Area Covered by Gimbal Housing Assembly - Flat to within 1/16 in. (1.6 mm)e - Transom Angle - 13 to 16f - Keel (If Equipped) - Remove keel 4 ft. (1.2 m) forward from transomChecking Transom ThicknessEnsure transom surface thickness and flatness conform to minimums specified in “<strong>Installation</strong>Specifications” listed previously.abc7000475479a - Measuring Thicknessb - Measuring Flatnessc - Suitable Mandrel To Check For Uniform Transom ThicknessNOTE: Transom must be between 2” (51 mm) and 2-1/4” (57 mm) a distance of 8” (203 mm)to either side of the vertical centerline.90-17431--4 MARCH 1998 Page 2A-3

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>Special InformationBravo Three Notice: Trim-In Limit Blocks or Limit SpacerNOTE: Some earlier Bravo Three models will be equipped with Trim-In Limit Blocks, latermodel Bravo One, Two and Three will have a Trim-In Limit Spacer. Refer to Section 4A forinformation on <strong>Removal</strong>, <strong>Installation</strong> or Adjustment of Trim-In Limit Blocks.It has been brought to our attention that some boats (predominantly deep-Vee heavy boats)will roll up on their side under certain, specific, operating conditions. The roll can be eitherto port or starboard and may be experienced while moving straight ahead, or while makinga turn. The roll occurs most frequently at or near maximum speed, with the drive unittrimmed at or near full IN. While the boat will not roll completely over, the roll may be sufficientto unseat the operator or passengers, and thereby create an unsafe situation.The roll is caused by stern lift. Stern lift can be created by excessive drive unit trim IN. Underthese extreme stern lift/bow down conditions instability can be created which may cause theboat to roll. Weight distribution to the stern can reduce stern lift and, in some circumstances,eliminate the condition. Weight distribution in the bow, port or starboard, may worsen thecondition.The Trim-in limit devices reduce stern lift by preventing the drive unit from reaching the lastfew degrees of full trim under. While this device should reduce the rolling tendency, they maynot eliminate the tendency entirely. The need for these trim-in limit blocks or spacer, and theeffectiveness of them, can only be determined through boat testing and is ultimately the responsibilityof the boat manufacturer.WARNINGIt is recommended that only qualified personnel remove or adjust the Trim-In LimitBlocks or adjust the Trim-In Limit Spacer. Boat must be water tested after removingor adjusting the device to ensure that the modified trim IN range does not cause theboat to exhibit an undesirable boat handling characteristic if the drive unit istrimmed IN at higher speeds. Increased trim IN range may cause handling problemson some boats which could result in personal injury.Page 2A-4 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTSIMPORTANT: On Bravo One, Two and Three Models, the “Trim-In Limit Spacer” (Ifequipped), must be properly positioned before installing the trim cylinder anchor pinin the following steps.NOTE: When removing the sterndrive unit, make a note of the position of the Spacer forreference when reinstalling the drive unit.1. If equipped, ensure that the Trim-In Limit Spacer is positioned as shown for the appropriateBravo model.aBravo One and Two (Positioned Forward)75157a75158Bravo Three (Positioned Aft)a - Trim-In Limit SpacerIMPORTANT: The position of the Trim-In Limit Spacer on the Bravo Three sterndriveunit should only be changed after the boat has been properly tested. Contact the boatmanufacturer if you are not sure of the original position for a particular boat application.90-17431--4 MARCH 1998 Page 2A-5

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>Sterndrive Unit <strong>Removal</strong>1. Shift remote control into neutral.2. Trim the drive unit to the full “up” position.CAUTIONAvoid speedometer hose fitting damage. Disconnect the speedometer hose fittingfrom the drive shaft housing before removing the sterndrive unit.3. Disconnect the speedometer hose fitting from the drive shaft housing.220254. Trim the drive unit to the full “down” position and remove the power trim cylinder fromthe aft end of the drive shaft housing.cdba22029a - End Capb - Nutc - Small I.D. Washerd - Rubber BushingPage 2A-6 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS5. Remove the locknuts holding the sterndrive onto the bell housing, then remove thesterndrive unit. Make sure the shift cable linkage jaws open and release the shift cableend.ba22031a - Locknuts and Washersb - Ground Plate (Continuity Washer Not Used Here)dc22025c - Shift Linkage Jaws (Open)d - Shift Cable End (Released from Jaws)90-17431--4 MARCH 1998 Page 2A-7

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>Transom Assembly <strong>Removal</strong>NOTE: When removing the transom assembly, it is not necessary to disconnect the powersteering hoses from the power steering control valve.1. Completely disconnect the power steering assembly.a. Disconnect the clevis pin from the steering lever.badcdc50352a - Clevisb - Steering Leverc - Cotter Pind - Clevis Pinb. Remove the cotter pin, clevis pin and lock plate (on earlier style control valve) to disconnectthe steering cable.bdacfe22023Earlier Style Control Valvea - Cable Endb - Clevisc - Cotter Pind - Clevis Pine - Lock Plate (Earlier Style Only)f - Coupler NutPage 2A-8 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTSbdcae71901Later Style Control Valvea - Cable Endb - Clevisc - Cotter Pind - Clevis Pine - Coupler Nutc. Remove the pivot bolt.d. Remove the power steering control valve and lay it on top of the engine.ab22023Earlier Style Control Valveab71901Later Style Control Valvea - Pivot Boltb - Control Valve90-17431--4 MARCH 1998 Page 2A-9

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>2. Disconnect the trim sender wires.3. Disconnect MerCathode wires from controller (if so equipped).From Engine HarnessaFrom Gimbal Housing24841Models With Bullet Connectors on Trim Sender Wiresa - Bullet Connectorsga b c d e f22032Models With Trim Sender Wire Connections At The MerCathode Controllera - ORANGE Lead - From Electrode on Transom Assemblyb - RED/PURPLE Lead - Connected (Other End) to Positive (+) Battery Terminalc - BLACK Lead - From Engine Harnessd - Trim Position Sender Leade - BROWN Lead - From Electrode on Transom Assemblyf - Trim Position Sender Leadg - BROWN/WHITE Lead - From Engine Harness4. Disconnect gear lube monitor warning horn wires, if so equipped.5. Remove engine (refer to appropriate engine service manual).6. Disconnect trim limit switch wires.7. Remove power trim pump hydraulic hoses and disconnect trim limit switch wires. Caphoses and plug pump fitting holes.cba - Sta-strapb - Trim Limit Switch Wiresc - Hydraulic Hosesa22031Page 2A-10 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS8. Follow step “a” for models with thru-prop exhaust and step “b” for models with thru-transomexhaust.a. Thru-prop exhaust models: remove exhaust pipe.b. Thru-transom exhaust models: it is not necessary to remove the block-off plateunless the gasket/mating surface is leaking or the exhaust system is to be modified(i.e. installing thru-prop exhaust; installing “Silent Choice” system, etc.).abba22028a - Exhaust Pipeb - Bolts (4)9. Remove the continuity wire from the steering lever.bca - Steering Leverb - Screwc - Continuity Wirea2202890-17431--4 MARCH 1998 Page 2A-<strong>11</strong>

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>10. Disconnect the speedometer hoses.abc22028Earlier Modelsa - Speedometer Hose (From Instrument Panel)b - Speedometer Hose (From Drive Unit)c - Mounting Clampa70015Later Modelsa - Speedometer Fitting<strong>11</strong>. Remove seawater intake hose, seawater pickup outlet, and gasket.daccb50275a - Seawater Intake Hoseb - Seawater Pickup Outletc - Bolts and Star Washersd - Gasket (Not Visible)Page 2A-12 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>12. On Diesel Models with Water Bypass Fitting - Remove fitting.REMOVAL, INSTALLATION AND ADJUSTMENTSba72045a - Water Bypass Fittingb - Installed Angle13. Models with Gear Lube Monitor:a. Disconnect gear lube monitor warning horn wires from engine harness.b. Remove gear lube monitor hose, hose clamp, and routing bracket.caba - Gear Lube Monitor Hoseb - Hose Clampc - Routing Bracket5036490-17431--4 MARCH 1998 Page 2A-13

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>14. Separate the inner transom plate from the gimbal housing assembly.aba50364Earlier Modela - Locknuts and Washersb - Bolts and Square WashersaaLater Modela - Locknuts and Washers73902Page 2A-14 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>Transom Assembly <strong>Installation</strong>REMOVAL, INSTALLATION AND ADJUSTMENTSCAUTIONAvoid leaks around the carriage head bolts. Rubber seal MUST BE installed on carriagehead bolts (if so equipped). Make sure that the rubber seal does not squeezeout beyond the bolt head when installing and tightening the bolt.ab22028a - Carriage Head Boltb - Rubber SealIMPORTANT: Torque bolts and nut (or studs and nuts if so equipped) evenly to 20-25lb. ft. (27-34 N·m). Tighten the center nuts first then work outward.CAUTIONAvoid continuity wire failure. Position the steering lever ground wire as shown orthe wire may fatigue and break.a - Steering Leverb - Transom Platec - Continuity Wireacb220281. Install the transom assembly. Tighten the attaching bolt and nut (earlier models) or studsand nuts (later models) evenly (starting from the center and working outward). Torqueto 20-25 lb. ft. (27-34 N·m).90-17431--4 MARCH 1998 Page 2A-15

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>afgebbhaicad50277Earlier Modela - Locknuts and Flat Washers (Securing Carriage Head Bolts)b - 4-1/4 in (108mm) Long Bolts, LockWashers, and Square Flat Washersc - Power Trim Hosesd - MerCathode Wirese - Continuity Wiref - Trim Limit and Trim Position Sender Wiresg - Grounding Bolth - Speedometer Hose (Earlier Models)i - Shift Cableagefdahbca73902Later Modela - Locknuts and Flat Washersb - Power Trim Hosesc - MerCathode Wiresd - Continuity Wiree - Trim Limit and Trim Position Sender Wiresf - Grounding Boltg - Speedometer Connectionh - Shift CablePage 2A-16 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS2. Models with Gear Lube Monitor - Install 90° hose fitting and position as shown. Torqueto 70-90 lb. in. (8-10 N·m).a-90° Hose Fittinga72046IMPORTANT: Hose must not come in contact with steering system components or theengine coupler and drive shaft.3. Install water inlet fitting with gasket. Connect gear lube monitor hose (if equipped) to 90°fitting and secure with hose clamp. Torque bolts and star washers to 45 lb. in. (5 N⋅m).acdb71998a - Hose to Gear Lube Monitorb - Hose Clampc - Water Inlet Fittingd - Bolts and Star Washers4. On Some Models with Gear Lube Monitor: The gear lube hose may be routed towardthe port side of the engine. If so, secure the hose at the top side of the water fitting usingthe hose clip as shown. Torque bolts and star washers to 45 lb. in. (5 N⋅m).dcaba - Gear Lube Monitor Hoseb - Hose Clampc - Hose Clipd - Water Hose Fittinge - Bolts and Star-Washerse7204790-17431--4 MARCH 1998 Page 2A-17

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>5. On D7.3L Diesel Models with Water Bypass Fitting - Apply Perfect Seal to threadsand install fitting. Tighten securely and position as shown.aa - Water Bypass Fitting6. On D7.3L Models - Install hose reducer as shown.72045ab72054a - Hose Reducerb - Water Inlet Fitting7. Connect water hoses to appropriate fittings and tighten hose clamps securely.baa - Seawater Hose (To Engine Seawater Pump)b - Seawater Pickup Hose72052Page 2A-18 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>8. Connect the speedometer hose.REMOVAL, INSTALLATION AND ADJUSTMENTSbacd22028 70015Earlier Modelsa - Speedometer Hose (From Instrument Panel)b - Speedometer Hose (From Drive Unit)c - Mount Clampd - Speedometer FittingLater ModelsIMPORTANT: Exhaust pipe or block-off plate, and gimbal housing mating surface,must be clean and free of nicks and scratches, and O-ring must be properly seatedin groove, or water may leak into boat.ba22030a - Mating Surfaceb - O-Ring90-17431--4 MARCH 1998 Page 2A-19

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>9. Thru-prop exhaust models: Install exhaust pipe. Torque bolts to 20-25 lb. ft. (27-34N·m).Typical V6 and V8 Gasoline Enginesa - Exhaust Pipeb - Boltsb22028ab72057a71945Typical Diesel Enginea - Exhaust Pipeb - BoltsPage 2A-20 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS10. Thru-transom exhaust models: Install exhaust block-off plate, if removed. Torquebolts to 20-25 lb. ft. (27-34 N·m).cba22030a - Block-off Plateb - Boltsc - No Bolt in This Hole on Earlier ModelsIMPORTANT: Make hydraulic hose connections as quick as possible to prevent oilfrom leaking out of the system.CAUTIONInstalling trim pump hoses improperly can damage the hose fittings and causeleaks or loose lines. Do not cross thread or overtighten the hose fittings.<strong>11</strong>. Connect the power trim pump hydraulic hoses. Torque both hose fittings to 100-150 lb.in. (<strong>11</strong>-16 N·m).aba-“Down” Pressure Hydraulic Line (Grey)b-“Up” Pressure Hydraulic Line (Black)2203190-17431--4 MARCH 1998 Page 2A-21

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>12. Install engine (refer to the appropriate engine service manual).13. Connect the power steering assembly to the transom.a. Lubricate bushings with Special Lubricant 101.aa2203371901Earlier Style Control Valvea - Special Lubricant 101Later Style Control Valveb. Slide the power steering cylinder bushings between the transom mounting brackets.Tighten the two pivot bolts by hand. At the same time, move the steering assemblyslightly to ensure proper pin engagement into the pivot bushings.c. Ensure that the washer tangs straddle the ridges on the inner transom plate.abbaa - Pivot Boltb - Washer Tang22033d. Torque the pivot bolts to 25 lb. ft. (34 N·m). Bend the washer tabs against the correspondingflats on both pivot bolt heads.e. Make sure the power steering control valve pivots freely.a22033a - Power Steering Control ValvePage 2A-22 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS14. Connect the power steering unit to the steering lever.a. Lubricate the clevis pins with Special Lubricant 101.b. Install the clevis pin in the clevis from the top.c. Secure the pin in the clevis with a cotter pin. Speed the cotter pin ends.15. Lubricate the steering cable end with a liberal amount of Special Lubricant 101 andinstall the cable through the guide.16. Connect the cable end to the clevis with the forward clevis pin. Spread the cotter pinends.17. Tighten the steering cable coupler nut. Torque to 35 lb. ft. (48 N·m).18. Earlier Style Control Valves: Install locking plate on the coupler nut and secure thecoupler nut with a screw and washer. Torque to 60-72 lb. in. (7-8 N·m).bafdfbaghecc50352Earlier Style Control Valvea - Rear Clevis Pinb - Clevisc - Cotter Pind - Steering Cable Ende - Cable Guidef - Forward Clevis Ping - Coupler Nuth - Locking Plate19. Later Style Control Valves: Using a suitable wrench hold the flat surfaces on the cableguide tube in the vertical position. Torque coupler nut to 35 lb. ft. (47 N·m). Be certainthe flat surfaces are still aligned vertically after torque is applied to coupler nut.aa - Flat Surface on Guide Tube7390190-17431--4 MARCH 1998 Page 2A-23

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>20. Later Style Control Valves: Torque the coupler nut to 35 lb. ft. (48 N·m).bafdea - Rear Clevis Pinb - Clevisc - Cotter Pind - Steering Cable Ende - Cable Guidef - Forward Clevis Ping - Coupler Nutgc7190121. Attach both hydraulic hose fittings.a. Earlier Style Control Valves: Torque the large fitting to 23 lb. ft. (31 N·m). Torquethe small fitting to 100 lb. in. (<strong>11</strong> N·m).aba - Small Fittingb - Large Fitting22023b. Later Style Control Valve: Torque both fittings to 23 lb. ft. (31 N·m). Route hosesas appropriate to avoid contact with the steering system components.ba73860Models With One Hose Routed Behind Power Steering Control Valvea - Rear Hose (Pressure Hose)b - Front Hose (Return Hose)Page 2A-24 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>aREMOVAL, INSTALLATION AND ADJUSTMENTSb74248Models With Both Hoses Routed Behind Power Steering Control Valve Toward StarboardSidea - Rear Hose (Pressure Hose)b - Front Hose (Return Hose)baModels With Both Hoses Routed Over Transom Platea - Rear Hose (Pressure Hose)b - Front Hose (Return Hose)7378622. Connect trim sender wires and MerCathodea. Earlier models with trim the sender wire connection at the MerCathode controller:Connect the electrical leads.ga b c d e f22032a - ORANGE Lead - From Electrode on Transom Assemblyb - RED/PURPLE Lead - Connected (Other End) to Positive (+) Battery Terminalc - BLACK Lead - From Engine Harnessd - Trim Position Sender Leade - BROWN Lead - From Electrode on Transom Assemblyf - Trim Position Sender Leadg - BROWN/WHITE Lead - From Engine Harnessb. Later Models with trim sender wire/engine harness connection: Connect thetrim sender leads from the gimbal housing to leads from the engine harness.ab24841a - Bullet Connectors - From Engine Harnessb - Bullet Connectors - From Transom Assembly90-17431--4 MARCH 1998 Page 2A-25

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>c. If not already done, connect the MerCathode wires at MerCathode controller.a b c d22232a - ORANGE Lead - From Electrode on Transom Assemblyb - RED/PURPLE Lead - Connect (Other End) to Positive (+) Battery Terminalc - BLACK Lead - From Engine Harnessd - BROWN Lead - From Electrode on Transom Assembly23. Apply a thin coat of Liquid Neoprene to all electrical connections.24. Connect the trim limit switch wires.ba - Sta-Strapb - Trim Limit Switch Wiresa2203125. Models With Transom Mounted Gear Lube Monitor: Connect the gear lube monitorwarning horn wires to the wires from the engine harness.a. Gasoline engine models: Connect wires (TAN/BLUE and BLACK) to matchingwires from engine harness (with bullet connectors).b. Diesel engine models: Connect the TAN/BLUE wire to the BLACK/GREEN wirefrom the engine harness (with bullet connectors). Connect the BLACK wires (withbullet connector).baa - Bullet Connectorsb - Warning Horn Wires50027Page 2A-26 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>Sterndrive Unit <strong>Installation</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS1. Install and align the engine (refer to the appropriate engine service manual).NOTE: If the engine was removed and the shift cable was disconnected, reinstall and adjustthe shift cable before proceeding (see page 2A-34).2. Place the remote control shift lever in the neutral position.3. Lubricate the bell housing studs with 2-4-C Marine Lubricant with Teflon.aaa - Bell Housing Studs247254. Lubricate the U-joint shaft splines and the O-rings with Engine Coupler Spline Grease.ba22026a - U-Joint Shaft Splinesb - U-Joint Shaft O-rings90-17431--4 MARCH 1998 Page 2A-27

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>IMPORTANT: The edge of the U-joint bellows acts as a seal between the bell housingand the drive shaft housing. Ensure that the surface is not damaged.aa - Drive Shaft Bellows Edge247255. Inspect the drive shaft bellows for cracks, nicks, and cleanliness. Replace or clean thebellows as necessary.6. Lubricate the O-ring seals on the face of the drive shaft housing.aa - O-Ring Seals22031Page 2A-28 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS7. Pull out the shift linkage as far as it moves. The jaws will open. Lubricate the undersideof the lower lip of the shift linkage assembly with Special Lubricant 101.bacca - Shift Linkage Assemblyb - Jaws - Openc - Underside of Lower Lip22025IMPORTANT: As you are inserting the sterndrive unit into the bell housing, the entranceof the bell housing shift cable must be closely checked to ensure that the cableenters the “Jaws” of the shift linkage assembly in the drive unit.NOTE: As the shift cable enters the shift linkage assembly, it pushes the assembly back intothe drive shaft housing, and the jaw closes, securing the cable as shown in A, B, and C (below).2202590-17431--4 MARCH 1998 Page 2A-29

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>NOTE: If the shift cable does not line up to properly enter the shift linkage jaws, use yourhand to guide the cable into place while installing the sterndrive unit.ab22025a - Shift Linkage Jawsb - Shift Cable8. Install the sterndrive unit.a. Position the trim cylinders so that they point straight backwards (aft).b. Align the universal joint shaft with the bell housing bore. Make sure the studs on thebell housing align with the appropriate holes on the drive unit.c. Guide the U-joint shaft through the gimbal bearing and into the engine coupler. Makesure that the shift linkage jaws engage with the shift cable.d. If necessary, rotate the propeller shaft slightly to align the U-joint shaft splines withthe engine coupler splines, then slide the drive unit completely into the bell housing.e. Rotate the propeller shaft slightly to ensure that the drive unit is still in neutral onceinstalled.9. Fasten the sterndrive unit to the bell housing. Start from the center and torque the nutsto 50 lb. ft. (68 N·m).aba22031a - Locknuts (6) and Flat Washers(5)b - Ground Plat (Continuity Washer Not Used Here)Page 2A-30 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTSIMPORTANT: On Bravo One, Two, and Three Models, the “Trim-In Limit Spacer” (Ifequipped), must be properly positioned before installing the trim cylinder anchor pinin the following steps.NOTE: Ensure that the Trim-In Limit Spacer is reinstalled in the same position that it wasin prior to removal of the sterndrive unit. If you are not sure of it’s original position, contactthe boat manufacturer for their recommendation. Refer to Special Information at the frontof this section before reinstalling the Trim-In Limit Spacer.10. If equipped, ensure that the Trim-In -Limit Spacer is positioned as shown for the appropriateBravo model.aBravo One and Two (Positioned Forward)a - Trim-In Limit Spacer75157aBravo Three (Positioned Aft)a - Trim-In Limit Spacer75158IMPORTANT: The position of the Trim-In Limit Spacer on the Bravo Three sterndriveunit should only be changed after the boat has been properly tested. Contact the boatmanufacturer if you are not sure of the original position for a particular boat application.IMPORTANT: Use a soap and water solution to aid in installing the rubber bushings.90-17431--4 MARCH 1998 Page 2A-31

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong><strong>11</strong>. Insert the aft anchor pin through the hole in the drive shaft housing. Then, place a largeI.D. flat washer and rubber bushing on each end of the anchor pin. Be sure to install thebushings with the small diameter end facing outward.ba cca - Anchor Pinb - Large I.D. Washersc - Rubber Bushings2202912. Loosen the nuts which secure the trim cylinders to the forward anchor pins. Move thecylinder pivot ends outward and place them over the aft anchor pin.NOTE: The bushings on Later Bravo drive units are made from a different type of material.The later style is harder. The bushing can also be identified by a small indentation on theoutside face of the bushing. Do not mix the earlier style rubber bushings with the later style.aa - Earlier Style Bushingb - Later Style Bushingc - Indentation on Later stylebc7527<strong>11</strong>3. Place the rubber bushings (with the smaller diameter end facing inward) and the smallI.D. flat washers onto each end of the anchor pin. Install plastic stop nuts.14. Tighten the forward and aft anchor pin nuts until the nuts and washers bottom outagainst anchor pin shoulder.Page 2A-32 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS15. Attach the trim cylinder caps. Hand tighten only. If the caps will not catch the threads,recheck the tightness of the anchor pin nuts.ceabd22029a - Trim Cylinder Pivot Endsb - Rubber Bushingc - Small I.D. Flat Washerd - Locknute - Trim Cylinder Cap16. Attach the speedometer hose fitting to the sterndrive unit.a. Raise the drive unit to gain access to the area between the gimbal housing and thedrive unit and locate the opening in the forward end of the anti-ventilation plate.b. Insert the speedometer hose fitting into the opening.aba - Speedometer Hose Fittingb - Opening2202590-17431--4 MARCH 1998 Page 2A-33

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>c. With the fitting fully seated, turn the handle clockwise to a tightly seated position.aa - Fitting Installed (Handle Pointing Forward)Shift Cable <strong>Installation</strong> and Adjustment22025NOTE: Using Adjustment Tool (91-12427), shift cables can be adjusted without or with thesterndrive installed, using the following procedure.IMPORTANT: Front propeller on Bravo Three drive unit is always LH rotation and rearpropeller is always RH rotation. Shift cable end guide must move in direction A, whencontrol lever is placed in Forward gear position.ABRAVO THREEIMPORTANT: For Bravo One and Two: Drive unit propeller rotation is determined bythe shift cable installation in the remote control.• If shift cable end guide moves in direction “A,” when control lever is placed inForward, remote control is setup for RIGHT HAND (RH) propeller rotation.• If shift cable end guide moves in direction “B,” when control lever is placed inForward, remote control is setup for LEFT HAND (LH) propeller rotation.71656ABBRAVO ONE AND TWO22024IMPORTANT: When installing shift cables, be sure that cables are routed in such away as to avoid sharp bends and/or contact with moving parts. DO NOT fasten anyitems to shift cables.Page 2A-34 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS1. Install shift cable into remote control. Refer to remote control manufacturer’s instructions.2. Loosen stud and move it to dimension, as shown. Retighten stud.ba71657a - Studb - 3 Inches (Center of Pivot Bolt to Center of Stud)3. Install drive unit shift cable.abc71658a - Washers (2)b - Locknut-Tighten Until Contact, Then Loosen 1 Turnc - Cotter Pin-Insert from Top and Spread Both Ends4. Place adjustment tool over drive unit shift cable, as shown. Hold tool in place over thebarrel retainer with a piece of tape.716595. Locate center of remote control and control cable play (backlash).a. Shift remote control to neutral.b. Push in on control cable end with enough pressure to remove play, and mark position“a” on tube.c. Pull out on control cable end with enough pressure to remove play and mark position“b” on tube.90-17431--4 MARCH 1998 Page 2A-35

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>d. Measure distance between marks “a” and “b.” Then, mark position “c” half-way betweenmarks “a” and “b.”bca71656IMPORTANT: Be sure to keep center mark “c” aligned with control cable end guideedge when making the following adjustment.6. Adjust control cable as follows:a. Temporarily install control cable end guide into shift lever and insert anchor pin.b. Adjust control cable barrel so that hole in barrel centers with vertical centerline ofstud. Ensure that backlash center mark is aligned with edge of control cable endguide.CAUTIONDO NOT attempt to install or remove control cable barrel from stud, without first removingend guide anchor pin from shift lever, and removing cable. Attempting tobend control cable to install or remove barrel, will place undue stress on cable endguide and shift lever, and damage to both could occur.c. Remove control cable end guide from shift lever, by removing anchor pin.bacde71660a - Control Cable End Guideb - Anchor Pinc - Backlash Centerd - Control Cable Barrele - StudPage 2A-36 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS7. Install control cable. Tighten locknut until it bottoms out. Spread both ends of cotter pin.bcdaa - Locknutb - Washers-Both Sides of Barrelc - Anchor Pind - Cotter Pin716618. Remove adjustment tool.9. Shift remote control lever into full forward position. Rear slot in tool should fit over shiftlever stud.RH ROTATION BRAVO ONE AND TWO, AND ALL BRAVO THREE MODELS: Rear slotin tool should fit over shift lever stud.LH ROTATION BRAVO ONE AND TWO MODELS: Forward slot in tool should fit over shiftlever stud.If slot does not fit over stud, loosen shift lever stud and slide stud up or down, until slot intool fits over stud. When adjustment is correct, retighten stud.dcabRH Rotation Bravo One <strong>And</strong> Two, <strong>And</strong> All Bravo Three Modelsd23345cabLH Rotation Bravo One <strong>And</strong> Two Modelsa-Adjustment Toolb-Barrel Retainerc-Shift Lever Studd-Shift Lever Adjustment Slot2334590-17431--4 MARCH 1998 Page 2A-37

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>10. Remove adjustment tool.<strong>11</strong>. Lubricate shift cable pivot points with 30W oil.Troubleshooting Shift ProblemsNOTE: The following information is provided to assist an installer in troubleshooting, if hardshifting or chucking/racheting is encountered when shifting into forward gear.1. When installing the control box in the side panel of the boat, make sure that the cableshave enough clearance to operate. This is necessary because the cables move up anddown when the shift handle is moved. If the control box is mounted too far back towardsany fiberglass structure, the cables will be interfered with, this will cause very hardshifting.NOTE: The control box housing can be rotated in 30° increments to improve cable routing.74688Proper Cable Bend74689Improper Cable Bend2. Make sure that when the shift cable from the control box is lead through the side gunnelof the hull, that it does not have any extremely sharp bends in it as this will cause thestiff shifting.Page 2A-38 90-17431--4 MARCH 1998

SERVICE MANUAL NUMBER <strong>11</strong>REMOVAL, INSTALLATION AND ADJUSTMENTS3. Before installing the shift cable into the control box, extend the stainless rod eye end ofthe cable and grease it with 2-4-C Marine Lubricant with Teflon. Move it back and forthto allow even distribution of the grease.220054. Do not strap or clamp the control cables to any other cables or rigid structure within threefeet of the control box.5. Be sure the cable is not permanently kinked.6. Make sure there is proper clearance for cable movement when the control box isinstalled in the side panel. The cables must have room to move up and down when thecontrol handle is shifted into either forward or reverse.7. Check to make sure that the engine was not set down on the intermediate shift cableduring installation, as this will crush the inner cable tubing and cause improper and / orstiff shifting.8. DO NOT fasten the shift cable with straps or clamps to any other cable within five feetof the shift plate.9. DO NOT fasten the shift cable to the transom with any type of plastic clips or fastenerswithin five feet of the shift plate.10. DO NOT overtighten the throttle or shift cable attaching nuts at the engine end. Barreland cable end must be free to rotate on the mounting stud.<strong>11</strong>. Check the intermediate shift cable routing from the transom assembly to the shift plateas follows:a. The cable should come through the transom, above the exhaust pipe and make aturn towards the starboard side of the boat between the exhaust pipe and the engineflywheel housing.b. The cable should then be routed under the starboard rear engine mount, and turntowards the transom.c. Then go up behind the power steering valve and loop over to the shift plate on theengine, where it is connected to the anchor points on the shift plate.Following this routing will prevent the engine coupler from damaging the cable.7490490-17431--4 MARCH 1998 Page 2A-39

REMOVAL, INSTALLATION AND ADJUSTMENTS SERVICE MANUAL NUMBER <strong>11</strong>THIS PAGE IS INTENTIONALLY BLANKPage 2A-40 90-17431--4 MARCH 1998