Quietpact 40G Diagnostic Repair Manual Model 4700 - Generac Parts

Quietpact 40G Diagnostic Repair Manual Model 4700 - Generac Parts

Quietpact 40G Diagnostic Repair Manual Model 4700 - Generac Parts

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

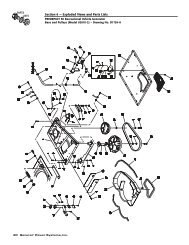

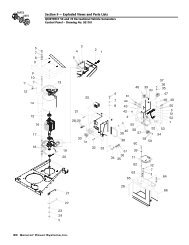

Section 2<br />

Major Generator Components<br />

Breather Assembly<br />

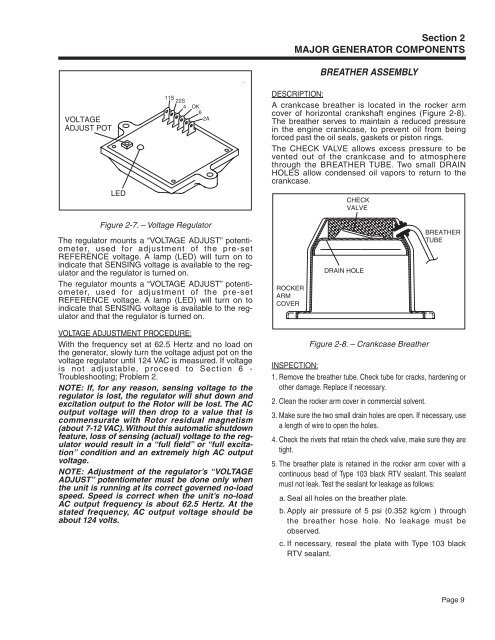

VOLTAGE<br />

ADjUST POT<br />

11S 22S<br />

4<br />

Ok<br />

6<br />

2A<br />

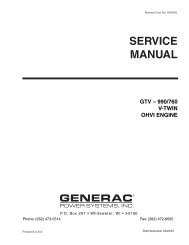

DESCRIPTION:<br />

A crankcase breather is located in the rocker arm<br />

cover of horizontal crankshaft engines (Figure 2-8).<br />

The breather serves to maintain a reduced pressure<br />

in the engine crankcase, to prevent oil from being<br />

forced past the oil seals, gaskets or piston rings.<br />

The CHECK VALVE allows excess pressure to be<br />

vented out of the crankcase and to atmosphere<br />

through the BREATHER TUBE. Two small DRAIN<br />

HOLES allow condensed oil vapors to return to the<br />

crankcase.<br />

LED<br />

CHECK<br />

VALVE<br />

Figure 2-7. – Voltage Regulator<br />

The regulator mounts a “VOLTAGE ADJUST” potentiometer,<br />

used for adjustment of the pre-set<br />

REFERENCE voltage. A lamp (LED) will turn on to<br />

indicate that SENSING voltage is available to the regulator<br />

and the regulator is turned on.<br />

The regulator mounts a “VOLTAGE ADJUST” potentiometer,<br />

used for adjustment of the pre-set<br />

REFERENCE voltage. A lamp (LED) will turn on to<br />

indicate that SENSING voltage is available to the regulator<br />

and that the regulator is turned on.<br />

ROCKER<br />

ARM<br />

COVER<br />

DRAIN HOLE<br />

BREATHER<br />

TUBE<br />

Voltage ADJUSTMENT PROCEDURE:<br />

With the frequency set at 62.5 Hertz and no load on<br />

the generator, slowly turn the voltage adjust pot on the<br />

voltage regulator until 124 VAC is measured. If voltage<br />

is not adjustable, proceed to Section 6 -<br />

Troubleshooting; Problem 2.<br />

NOTE: If, for any reason, sensing voltage to the<br />

regulator is lost, the regulator will shut down and<br />

excitation output to the Rotor will be lost. The AC<br />

output voltage will then drop to a value that is<br />

commensurate with Rotor residual magnetism<br />

(about 7-12 VAC). Without this automatic shutdown<br />

feature, loss of sensing (actual) voltage to the regulator<br />

would result in a “full field” or “full excitation”<br />

condition and an extremely high AC output<br />

voltage.<br />

NOTE: Adjustment of the regulator’s “VOLTAGE<br />

ADJUST” potentiometer must be done only when<br />

the unit is running at its correct governed no-load<br />

speed. Speed is correct when the unit’s no-load<br />

AC output frequency is about 62.5 Hertz. At the<br />

stated frequency, AC output voltage should be<br />

about 124 volts.<br />

Figure 2-8. – Crankcase Breather<br />

INSPECTION:<br />

1. Remove the breather tube. Check tube for cracks, hardening or<br />

other damage. Replace if necessary.<br />

2. Clean the rocker arm cover in commercial solvent.<br />

3. Make sure the two small drain holes are open. If necessary, use<br />

a length of wire to open the holes.<br />

4. Check the rivets that retain the check valve, make sure they are<br />

tight.<br />

5. The breather plate is retained in the rocker arm cover with a<br />

continuous bead of Type 103 black RTV sealant. This sealant<br />

must not leak. Test the sealant for leakage as follows:<br />

a. Seal all holes on the breather plate.<br />

b. Apply air pressure of 5 psi (0.352 kg/cm ) through<br />

the breather hose hole. No leakage must be<br />

observed.<br />

c. If necessary, reseal the plate with Type 103 black<br />

RTV sealant.<br />

Page 9