Quietpact 40G Diagnostic Repair Manual Model 4700 - Generac Parts

Quietpact 40G Diagnostic Repair Manual Model 4700 - Generac Parts

Quietpact 40G Diagnostic Repair Manual Model 4700 - Generac Parts

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Section 7<br />

DIAGNOSTIC TESTS<br />

Introduction<br />

The “<strong>Diagnostic</strong> Tests” in this chapter may be performed<br />

in conjunction with the “Flow Charts” of<br />

Section 6. Test numbers in this chapter correspond to<br />

the numbered tests in the “Flow Charts”.<br />

Tests 1 through 17 are procedures Involving problems<br />

with the generator’s AC output voltage and frequency<br />

(Problems 1 through 4 in the “Flow Charts”).<br />

Tests 18 through 40 are procedures involving problems<br />

with engine operation (Problems 5 through 9 in the<br />

“Troubleshooting Flow Charts”).<br />

You may wish to read Section 4, “Measuring<br />

Electricity”.<br />

NOTE: Test procedures in this <strong>Manual</strong> are not<br />

necessarily the only acceptable methods for diagnosing<br />

the condition of components and circuits.<br />

All possible methods that might be used for system<br />

diagnosis have not been evaluated. If you<br />

use any diagnostic method other than the method<br />

presented in this <strong>Manual</strong>, you must ensure<br />

that nether neither your safety nor the product’s<br />

safety will be endangered by the procedure or<br />

method you have selected.<br />

Test 1 – Check No-Load Voltage and<br />

Frequency<br />

DISCUSSION:<br />

The first step in analyzing any problem with the AC<br />

generator is to determine the unit’s AC output voltage<br />

and frequency. Once that has been done, you will<br />

know how to proceed with specific diagnostic tests.<br />

PROCEDURE:<br />

1. Set a volt-ohm-milliammeter (VOM) to read AC voltage. Connect<br />

the meter test leads across customer connection leads T1<br />

(Red) and T2 (White).<br />

2. Disconnect or turn OFF all electrical loads. Initial checks and<br />

adjustments are accomplished at no-load.<br />

3. Start the engine, let it stabilize and warm up.<br />

4. Read the AC voltage.<br />

5. Connect an AC frequency meter across AC output leads T1<br />

(Black) and T2 (White). Repeat the above procedure.<br />

RESULTS:<br />

For units rated 60 Hertz, no-load voltage and frequency<br />

should be approximately 122-126 VAC and 61-63<br />

Hertz respectively.<br />

1. If AC voltage and frequency are BOTH correspondingly high or<br />

low, go to Test 2.<br />

2. If AC frequency is good but low or residual voltage is indicated,<br />

go to Test 3.<br />

3. If AC output voltage and frequency are both “zero”, go to Test 12.<br />

4. If the no-load voltage and frequency are within the stated limits,<br />

go to Test 13.<br />

NOTE: The term “low voltage” refers to any voltage<br />

reading that is lower than the unit’s rated voltage.<br />

The term “residual voltage” refers to the output<br />

voltage supplied as a result of Rotor residual magnetism<br />

(approximately 5-12 VAC).<br />

Test 2 – Check Engine Governor<br />

DISCUSSION:<br />

Rotor operating speed and AC output frequency are<br />

proportional. The generator will deliver a frequency of<br />

60 Hertz at 3600 Rotor rpm or 62 Hertz at 3720<br />

Rotor rpm.<br />

The Voltage Regulator should be adjusted to deliver<br />

120 VAC (line-to-neutral) at a frequency of 60 Hertz or<br />

124 VAC (line-to-neutral at 62 Hertz. It is apparent<br />

that, if governed speed is high or low, AC frequency<br />

and voltage will be correspondingly high or low.<br />

Governed speed at no-load is usually set slightly<br />

above the rated speed of 60 Hertz (to 62 Hertz), to<br />

prevent excessive rpm, frequency and voltage droop<br />

under heavy electrical loading.<br />

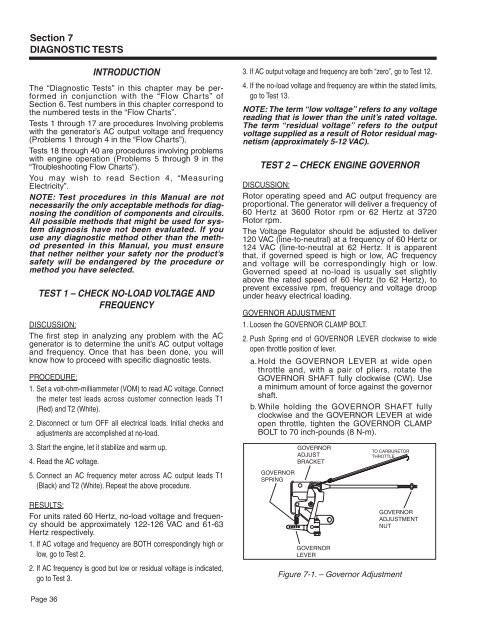

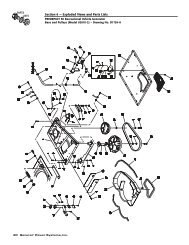

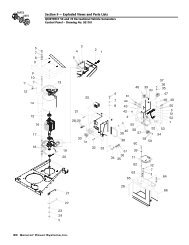

Governor Adjustment<br />

1. Loosen the GOVERNOR CLAMP BOLT.<br />

2. Push Spring end of GOVERNOR LEVER clockwise to wide<br />

open throttle position of lever.<br />

a. Hold the GOVERNOR LEVER at wide open<br />

throttle and, with a pair of pliers, rotate the<br />

GOVERNOR SHAFT fully clockwise (CW). Use<br />

a minimum amount of force against the governor<br />

shaft.<br />

b. While holding the GOVERNOR SHAFT fully<br />

clockwise and the GOVERNOR LEVER at wide<br />

open throttle, tighten the GOVERNOR CLAMP<br />

BOLT to 70 inch-pounds (8 N-m).<br />

GOVERNOR<br />

SPRING<br />

GOVERNOR<br />

ADjUST<br />

BRACkET<br />

GOVERNOR<br />

LEVER<br />

TO CARBURETOR<br />

THROTTLE<br />

GOVERNOR<br />

ADjUSTMENT<br />

NUT<br />

Figure 7-1. – Governor Adjustment<br />

Page 36