Liquid-Level Sensors - MTS Sensors

Liquid-Level Sensors - MTS Sensors

Liquid-Level Sensors - MTS Sensors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.0 INSTALLATION AND MOUNTING<br />

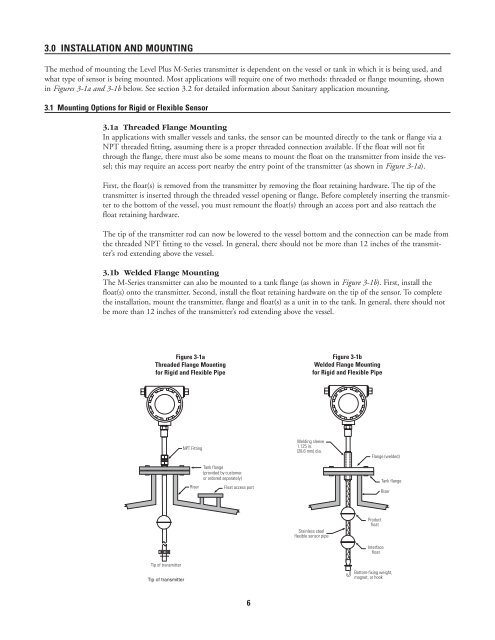

The method of mounting the <strong>Level</strong> Plus M-Series transmitter is dependent on the vessel or tank in which it is being used, and<br />

what type of sensor is being mounted. Most applications will require one of two methods: threaded or flange mounting, shown<br />

in Figures 3-1a and 3-1b below. See section 3.2 for detailed information about Sanitary application mounting.<br />

3.1 Mounting Options for Rigid or Flexible Sensor<br />

3.1a Threaded Flange Mounting<br />

In applications with smaller vessels and tanks, the sensor can be mounted directly to the tank or flange via a<br />

NPT threaded fitting, assuming there is a proper threaded connection available. If the float will not fit<br />

through the flange, there must also be some means to mount the float on the transmitter from inside the vessel;<br />

this may require an access port nearby the entry point of the transmitter (as shown in Figure 3-1a).<br />

First, the float(s) is removed from the transmitter by removing the float retaining hardware. The tip of the<br />

transmitter is inserted through the threaded vessel opening or flange. Before completely inserting the transmitter<br />

to the bottom of the vessel, you must remount the float(s) through an access port and also reattach the<br />

float retaining hardware.<br />

The tip of the transmitter rod can now be lowered to the vessel bottom and the connection can be made from<br />

the threaded NPT fitting to the vessel. In general, there should not be more than 12 inches of the transmitter’s<br />

rod extending above the vessel.<br />

3.1b Welded Flange Mounting<br />

The M-Series transmitter can also be mounted to a tank flange (as shown in Figure 3-1b). First, install the<br />

float(s) onto the transmitter. Second, install the float retaining hardware on the tip of the sensor. To complete<br />

the installation, mount the transmitter, flange and float(s) as a unit in to the tank. In general, there should not<br />

be more than 12 inches of the transmitter’s rod extending above the vessel.<br />

Figure 3-1a<br />

Threaded Flange Mounting<br />

for Rigid and Flexible Pipe<br />

Figure 3-1b<br />

Welded Flange Mounting<br />

for Rigid and Flexible Pipe<br />

NPT Fitting<br />

Riser<br />

Tank flange<br />

(provided by customer<br />

or ordered separately)<br />

Float access port<br />

Welding sleeve<br />

1.125 in.<br />

(28.6 mm) dia.<br />

Flange (welded)<br />

Tank flange<br />

Riser<br />

Stainless steel<br />

flexible sensor pipe<br />

Product<br />

float<br />

Interface<br />

float<br />

Tip of transmitter<br />

Tip of transmitter<br />

Bottom-fixing weight,<br />

magnet, or hook<br />

6