Chemical Anchor Technical Handbook

Chemical Anchor Technical Handbook

Chemical Anchor Technical Handbook

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Product Details<br />

CF900 TROPIC <strong>Technical</strong> Information<br />

<strong>Chemical</strong> <strong>Anchor</strong>ing<br />

Product Overview<br />

<strong>Chemical</strong> <strong>Anchor</strong>ing<br />

Theory<br />

Contents<br />

Applications<br />

1. Areas of<br />

Application<br />

2. Benefits<br />

3. Properties<br />

Usage Instructions<br />

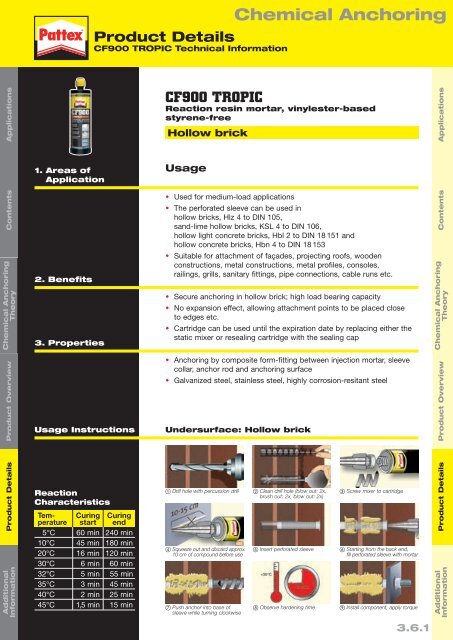

CF900 TROPIC<br />

Reaction resin mortar, vinylester-based<br />

styrene-free<br />

Hollow brick<br />

Usage<br />

• Used for medium-load applications<br />

• The perforated sleeve can be used in<br />

hollow bricks, Hlz 4 to DIN 105,<br />

sand-lime hollow bricks, KSL 4 to DIN 106,<br />

hollow light concrete bricks, Hbl 2 to DIN 18 151 and<br />

hollow concrete bricks, Hbn 4 to DIN 18 153<br />

• Suitable for attachment of façades, projecting roofs, wooden<br />

constructions, metal constructions, metal profiles, consoles,<br />

railings, grills, sanitary fittings, pipe connections, cable runs etc.<br />

• Secure anchoring in hollow brick; high load bearing capacity<br />

• No expansion effect, allowing attachment points to be placed close<br />

to edges etc.<br />

• Cartridge can be used until the expiration date by replacing either the<br />

static mixer or resealing cartridge with the sealing cap<br />

• <strong>Anchor</strong>ing by composite form-fitting between injection mortar, sleeve<br />

collar, anchor rod and anchoring surface<br />

• Galvanized steel, stainless steel, highly corrosion-resitant steel<br />

Undersurface: Hollow brick<br />

Product Overview<br />

<strong>Chemical</strong> <strong>Anchor</strong>ing<br />

Contents Applications<br />

Theory<br />

Product Details<br />

Additional<br />

Information<br />

Reaction<br />

Characteristics<br />

Temperature<br />

Curing<br />

start<br />

Curing<br />

end<br />

5°C 60 min 240 min<br />

10°C 45 min 180 min<br />

20°C 16 min 120 min<br />

30°C 6 min 60 min<br />

32°C 5 min 55 min<br />

35°C 3 min 45 min<br />

40°C 2 min 25 min<br />

45°C 1,5 min 15 min<br />

Drill hole with percussion drill Clean drill hole (blow out: 2x,<br />

brush out: 2x, blow out: 2x)<br />

Squeeze out and discard approx.<br />

10 cm of compound before use<br />

Push anchor into base of<br />

sleeve while turning clockwise<br />

Insert perforated sleeve<br />

Observe hardening time<br />

Screw mixer to cartridge<br />

Starting from the back end,<br />

fill perforated sleeve with mortar<br />

Install component, apply torque<br />

Product Details<br />

Additional<br />

Information<br />

3.6.1