METHOD STATEMENT Boiler Clean out - Vital Energi

METHOD STATEMENT Boiler Clean out - Vital Energi

METHOD STATEMENT Boiler Clean out - Vital Energi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

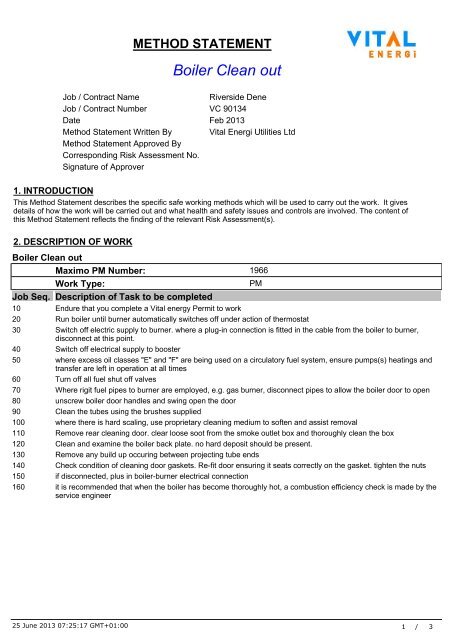

<strong>METHOD</strong> <strong>STATEMENT</strong><br />

<strong>Boiler</strong> <strong>Clean</strong> <strong>out</strong><br />

Job / Contract Name<br />

Riverside Dene<br />

Job / Contract Number VC 90134<br />

Date Feb 2013<br />

Method Statement Written By <strong>Vital</strong> <strong>Energi</strong> Utilities Ltd<br />

Method Statement Approved By<br />

Corresponding Risk Assessment No.<br />

Signature of Approver<br />

1. INTRODUCTION<br />

This Method Statement describes the specific safe working methods which will be used to carry <strong>out</strong> the work. It gives<br />

details of how the work will be carried <strong>out</strong> and what health and safety issues and controls are involved. The content of<br />

this Method Statement reflects the finding of the relevant Risk Assessment(s).<br />

2. DESCRIPTION OF WORK<br />

<strong>Boiler</strong> <strong>Clean</strong> <strong>out</strong><br />

Maximo PM Number: 1966<br />

Work Type:<br />

PM<br />

Job Seq. Description of Task to be completed<br />

10 Endure that you complete a <strong>Vital</strong> energy Permit to work<br />

20 Run boiler until burner automatically switches off under action of thermostat<br />

30 Switch off electric supply to burner. where a plug-in connection is fitted in the cable from the boiler to burner,<br />

disconnect at this point.<br />

40 Switch off electrical supply to booster<br />

50 where excess oil classes "E" and "F" are being used on a circulatory fuel system, ensure pumps(s) heatings and<br />

transfer are left in operation at all times<br />

60 Turn off all fuel shut off valves<br />

70 Where rigit fuel pipes to burner are employed, e.g. gas burner, disconnect pipes to allow the boiler door to open<br />

80 unscrew boiler door handles and swing open the door<br />

90 <strong>Clean</strong> the tubes using the brushes supplied<br />

100 where there is hard scaling, use proprietary cleaning medium to soften and assist removal<br />

110 Remove rear cleaning door. clear loose soot from the smoke <strong>out</strong>let box and thoroughly clean the box<br />

120 <strong>Clean</strong> and examine the boiler back plate. no hard deposit should be present.<br />

130 Remove any build up occuring between projecting tube ends<br />

140 Check condition of cleaning door gaskets. Re-fit door ensuring it seats correctly on the gasket. tighten the nuts<br />

150 if disconnected, plus in boiler-burner electrical connection<br />

160 it is recommended that when the boiler has become thoroughly hot, a combustion efficiency check is made by the<br />

service engineer<br />

25 June 2013 07:25:17 GMT+01:00 1 / 3

3. LOCATION / ASSET OF WORK<br />

Location<br />

Asset<br />

EC-B1<br />

4. Access Arrangements<br />

Give details of any special access or egress arrangements that will be used.<br />

5. Licence<br />

If a licence is required for this work, give details of licence required, who holds it and where a copy of this licence is<br />

stored e.g. Asbestos, C.O.R.G.I. Registration.<br />

25 June 2013 07:25:17 GMT+01:00 2 / 3

25 June 2013 07:25:17 GMT+01:00 3 / 3