DST 135-315 Three-phase synchronous high-torque

DST 135-315 Three-phase synchronous high-torque

DST 135-315 Three-phase synchronous high-torque

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

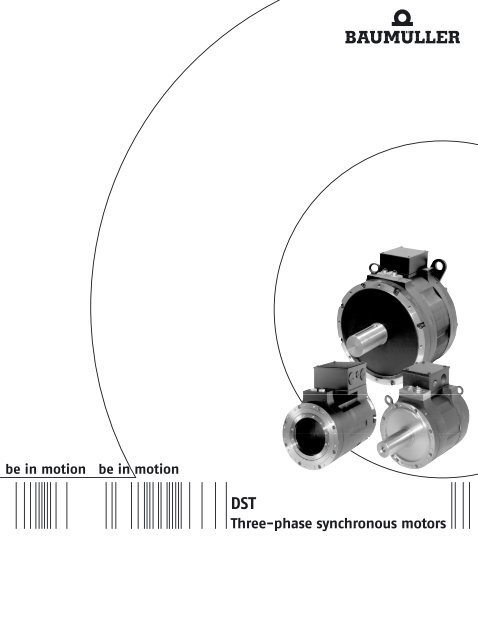

e in motion be in motion<br />

<strong>DST</strong><br />

<strong>Three</strong>-<strong>phase</strong> <strong>synchronous</strong> motors

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Table of Contents<br />

Synchronous Torque Motor <strong>DST</strong>............................................................................................................................2<br />

General technical data ........................................................................................................................................2<br />

Ratings definition.................................................................................................................................................3<br />

Winding isolation and temperature rise...............................................................................................................3<br />

Explanation of the motor data .............................................................................................................................3<br />

Type key..............................................................................................................................................................4<br />

Technical data.....................................................................................................................................................5<br />

<strong>DST</strong> <strong>135</strong> 54 W (IP 54 water-cooled) .................................................................................................................5<br />

<strong>DST</strong> 200 54 W (IP 54 water-cooled) .................................................................................................................6<br />

<strong>DST</strong> 260 54 W (IP 54 water-cooled) .................................................................................................................7<br />

<strong>DST</strong> <strong>315</strong> 54 W (IP 54 water-cooled) .................................................................................................................8<br />

Dimension drawing..............................................................................................................................................9<br />

<strong>DST</strong> <strong>135</strong> ............................................................................................................................................................9<br />

<strong>DST</strong> <strong>135</strong> – Hollow shaft version ( ∅hollow shaft 150mm )....................................................................................10<br />

<strong>DST</strong> 200 ..........................................................................................................................................................11<br />

<strong>DST</strong> 200– Hollow shaft version ( ∅hollow shaft 150mm ).....................................................................................12<br />

<strong>DST</strong> 260 ..........................................................................................................................................................13<br />

<strong>DST</strong> <strong>315</strong> ..........................................................................................................................................................14<br />

<strong>DST</strong> – kit..........................................................................................................................................................15<br />

Bearings and shaft load ....................................................................................................................................16<br />

Radial force diagrams .......................................................................................................................................17<br />

Main connection – Terminal box .......................................................................................................................20<br />

Thermal sensor .................................................................................................................................................21<br />

Cooling circuit requirements for water-cooled motors ......................................................................................21<br />

Details relating to the amounts of coolant required ..........................................................................................22<br />

Encoder.............................................................................................................................................................23<br />

SINCOS SRS/SRM 50 (SICK|STEGMANN) (Option).....................................................................................23<br />

ECN 1313 EQN 1325 (Heidenhain) ...............................................................................................................24<br />

Resolver (on request) ......................................................................................................................................25<br />

Dimension drawing of encoder connectors .....................................................................................................26<br />

Encoder cables .................................................................................................................................................27<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 1

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Synchronous Torque Motor <strong>DST</strong><br />

General technical data<br />

The <strong>torque</strong> motors of the <strong>DST</strong> series are permanently excited, <strong>high</strong><br />

pole, water-cooled <strong>synchronous</strong> motors.<br />

The <strong>high</strong> <strong>torque</strong> densities in the low and medium speed ranges<br />

make this energy-efficient motor series ideal for use as a direct drive<br />

in general mechanical engineering applications.<br />

The drives have a <strong>high</strong> overload capability and display true running<br />

characteristics and are therefore ideal for sophisticated and dynamic<br />

applications.<br />

The integrated water-cooling system paves the way for optimal<br />

dissipation of losses with a <strong>high</strong> protection type. A fan is not required<br />

with these motors thus leading to a significant reduction in noise<br />

emissions.<br />

Moreover, these durable, compact motors are also largely<br />

maintenance-free, which is an extra benefit to ensure efficient<br />

operation.<br />

Version IM B14, B3 Frame size <strong>135</strong> / 200 (other versions available on request)<br />

IM B34, B3 Frame size 200 / 260/ <strong>315</strong> (other versions available on<br />

request)<br />

Type of protection IP54<br />

Connection Main connection U V W (terminal box)<br />

Control connection 12-pin connector<br />

Thermal sensor in the main connection<br />

Cooling method IC 3W7 water-cooled<br />

Coolant input temperature 10°C to 35°C For details of how ambient temperature/humidity can affect<br />

the accumulation of condensed water (and how this<br />

phenomenon can be avoided), see page 21.<br />

Thermal sensor linear thermal sensor for evaluation in the controller<br />

Temperature rise Δϑ ≤ 105K<br />

<strong>DST</strong><strong>135</strong>/ 200/ <strong>315</strong> Insulation class F acc. to EN 60034<br />

Δϑ ≤ 125K<br />

<strong>DST</strong>260 Insulation class H acc. to EN 60034<br />

Ambient temperature 0....+ 40°C<br />

Storage -30°C...+85°C for temperatures lower than 3 °C the cooling-water must be<br />

drained<br />

Terminal box B-side; top other positions on request<br />

Water connections A-side; top other positions on request<br />

Balance quality A according to DIN EN60034-14 (VDE 0530-Part14):2004-09<br />

Vibration resistance radial 3g / axial 1g 10 – 55 Hz acc. to EN 60068-2-6<br />

Shaft end cylindrical according to DIN 748 without key<br />

centering with internal thread acc. to DIN 332 form D<br />

Also available with key DIN 6885 (option) (observe <strong>torque</strong>)<br />

Surface black matt RAL 9005<br />

Actual speed encoder Sincos Encoder<br />

Resolver (option)<br />

other encoders on request<br />

Mounted via belt in the case of the hollow-shaft version<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

2 Baumüller Nürnberg GmbH

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Ratings definition<br />

The ratings (<strong>torque</strong>s) listed in the table apply to continuous operation (S1) with nominal speed provided that the<br />

requirements that apply for the cooling circuit in liquid-cooled motors are observed (cf. P. 21)!<br />

Winding isolation and temperature rise<br />

The <strong>DST</strong><strong>135</strong>/200/<strong>315</strong> motors feature insulation class F in accordance with EN 60034 and have been designed for a<br />

permissible winding temperature of 105 K at a water intake temperature of up to 35°C. The <strong>DST</strong>260 features insulation<br />

class H in accordance with EN 60034 and has been designed for a permissible winding temperature of 125 K at a water<br />

intake temperature of up to 35°C.<br />

The insulation is resistant against gases and vapors of combustible materials and it meets the requirements expected of a<br />

moisture-proof and tropical insulation.<br />

Special insulation is necessary if concentrated acid vapors occur, if the permanent relative air humidity is more than 80%<br />

and as protection against termite and mould fungus attacks.<br />

In the case of converters with a DC link voltage > 500 V, the cables between the converter and the motor must not be<br />

longer than 20 meters. For longer cables, additional measures (e.g. motor filters) must be provided. The maximum<br />

permissible terminal voltage is 1000 V.<br />

Explanation of the motor data<br />

nN Nominal speed [min -1 ]<br />

PN Nominal power [kW] with MN and nN (see ratings definition)<br />

MN Nominal <strong>torque</strong> [Nm]<br />

IN Nominal r.m.s. current [A]<br />

UN Nominal voltage [V]<br />

KE / COLD Voltage constant (e.m.f.) at [V per 100 min -1 ]<br />

cos ϕ Power factor<br />

IdN Magnetizing current in field weakening operation [A]<br />

ηN Efficiency<br />

fN Nominal frequency [Hz]<br />

Mo,max Maximum standstill <strong>torque</strong> [Nm]<br />

Io,max Standstill current [A] with Mo,max<br />

m Weight of motor [kg]<br />

Inertia [kgm²]<br />

Jmot<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 3

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Type key<br />

<strong>DST</strong> <strong>135</strong> M 54 W 75 -5<br />

DC link<br />

voltage: 5 540 V<br />

X Special<br />

Nominal speed: e.g.<br />

75 =<br />

750 min -1<br />

Cooling method: W Water cooling<br />

Type of protection: 54= IP54<br />

00= IP00 Bausatz<br />

Length: K<br />

M<br />

L<br />

B<br />

X<br />

Frame size: <strong>135</strong><br />

200<br />

260<br />

<strong>315</strong><br />

Motor type: <strong>DST</strong> <strong>Three</strong>-<strong>phase</strong><br />

Synchronous<br />

Torque<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

4 Baumüller Nürnberg GmbH

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Technical data<br />

<strong>DST</strong> <strong>135</strong> 54 W (IP 54 water-cooled)<br />

Mains voltage 3 AC 400 V for converters with uncontrolled supply<br />

nN Typ PN PN MN MN IN UN KE / COLD cos<br />

ϕ<br />

- A - Hz A Nm lbf ft<br />

min -1 kW hp Nm lbf ft A V V/100min -<br />

1<br />

IdN ηN fN Io,max Mo,max Mo,max<br />

350 <strong>DST</strong><strong>135</strong>K54W35-5 5,8 7,78 158 117 12,5 350 82,9 0,95 0 0,82 58,3 28 345 254<br />

<strong>DST</strong><strong>135</strong>M54W35-5 8,8 11,8 240 177 18 355 85,7 0,94 0 0,835 58,3 41 510 376<br />

<strong>DST</strong><strong>135</strong>L54W35-5 11,9 16 324 239 24,5 350 85,3 0,94 0 0,841 58,3 55 680 502<br />

<strong>DST</strong><strong>135</strong>B54W35-5 14,7 19,7 402 296 29,5 355 88,6 0,96 2 0,845 58,3 65 845 623<br />

550 <strong>DST</strong><strong>135</strong>K54W55-5 9,1 12,2 158 117 18,5 350 55,9 0,94 0 0,866 91,7 42 345 254<br />

<strong>DST</strong><strong>135</strong>M54W55-5 13,7 18,4 238 176 27,5 350 56,2 0,94 0 0,878 91,7 62 510 376<br />

<strong>DST</strong><strong>135</strong>L54W55-5 18,5 24,8 321 237 36,5 355 56,8 0,94 0 0,882 91,7 82 680 502<br />

<strong>DST</strong><strong>135</strong>B54W55-5 23,0 30,8 400 295 45 355 57,6 0,94 0 0,886 91,7 100 845 623<br />

750 <strong>DST</strong><strong>135</strong>K54W75-5 12,3 16,5 157 116 24,5 345 41,4 0,94 0 0,887 125 57 345 254<br />

<strong>DST</strong><strong>135</strong>M54W75-5 18,5 24,8 235 173 35,5 355 42,8 0,94 0 0,897 125 82 510 376<br />

<strong>DST</strong><strong>135</strong>L54W75-5 25,0 33,5 319 235 49 355 42,6 0,94 0 0,901 125 109 680 502<br />

<strong>DST</strong><strong>135</strong>B54W75-5 30,5 40,9 389 287 58 350 44,3 0,96 6 0,902 125 130 845 623<br />

1000 <strong>DST</strong><strong>135</strong>K54W100-5 16,0 21,5 153 113 31,3 350 32,5 0,95 1 0,89 166,6 73 345 254<br />

<strong>DST</strong><strong>135</strong>M54W100-5 23,5 31,5 224 165 43 350 34,8 0,98 8 0,907 166,6 100 510 376<br />

<strong>DST</strong><strong>135</strong>L54W100-5 32,0 42,9 306 226 62 350 32 0,94 0 0,912 166,6 145 680 502<br />

<strong>DST</strong><strong>135</strong>B54W100-5 37,8 50,7 361 266 71 345 35,5 0,99 19 0,91 166,6 170 845 623<br />

nN Typ Jmot Jmot Jmot Jmot m m m m<br />

min -1 [kgm²] lb ft² [kgm²] lb ft² [kg] lb [kg] lb<br />

solid<br />

hollow<br />

solid<br />

hollow<br />

shaft<br />

shaft<br />

shaft<br />

shaft<br />

350 <strong>DST</strong><strong>135</strong>K54W35-5 0,14 3,32 0,16 3,80 97 214 74 163<br />

<strong>DST</strong><strong>135</strong>M54W35-5 0,18 4,27 0,19 4,51 117 258 90 198<br />

<strong>DST</strong><strong>135</strong>L54W35-5 0,23 5,46 0,21 4,98 124 273 104 229<br />

<strong>DST</strong><strong>135</strong>B54W35-5 0,28 6,64 0,24 5,70 156 344 116 256<br />

550 <strong>DST</strong><strong>135</strong>K54W55-5 0,14 3,32 0,16 3,80 97 214 74 163<br />

<strong>DST</strong><strong>135</strong>M54W55-5 0,18 4,27 0,19 4,51 117 258 90 198<br />

<strong>DST</strong><strong>135</strong>L54W55-5 0,23 5,46 0,21 4,98 124 273 104 229<br />

<strong>DST</strong><strong>135</strong>B54W55-5 0,28 6,64 0,24 5,70 156 344 116 256<br />

750 <strong>DST</strong><strong>135</strong>K54W75-5 0,14 3,32 0,16 3,80 97 214 74 163<br />

<strong>DST</strong><strong>135</strong>M54W75-5 0,18 4,27 0,19 4,51 117 258 90 198<br />

<strong>DST</strong><strong>135</strong>L54W75-5 0,23 5,46 0,21 4,98 124 273 104 229<br />

<strong>DST</strong><strong>135</strong>B54W75-5 0,28 6,64 0,24 5,70 156 344 116 256<br />

1000 <strong>DST</strong><strong>135</strong>K54W100-5 0,14 3,32 0,16 3,80 97 214 74 163<br />

<strong>DST</strong><strong>135</strong>M54W100-5 0,18 4,27 0,19 4,51 117 258 90 198<br />

<strong>DST</strong><strong>135</strong>L54W100-5 0,23 5,46 0,21 4,98 124 273 104 229<br />

<strong>DST</strong><strong>135</strong>B54W100-5 0,28 6,64 0,24 5,70 156 344 116 256<br />

Legend<br />

American units<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 5

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

<strong>DST</strong> 200 54 W (IP 54 water-cooled)<br />

Mains voltage 3 AC 400 V for converters with uncontrolled supply<br />

nN Typ PN PN MN MN IN UN KE / COLD cos<br />

ϕ<br />

kW hp Nm lbf ft A V V/100min -<br />

- A - Hz A Nm lbf ft<br />

min -<br />

1<br />

IdN ηN fN Io,max Mo,max Mo,max<br />

150 <strong>DST</strong>200K54W15-5 6,1 8,18 388 286 13,7 355 183,9 0,92 0 0,784 37,5 35 890 656<br />

<strong>DST</strong>200M54W15-5 12,4 16,6 790 583 28 350 184,4 0,91 0 0,805 37,5 69 1740 1283<br />

<strong>DST</strong>200L54W15-5- 18,5 24,8 1180 870 41 350 185,1 0,91 0 0,815 37,5 102 2600 1918<br />

<strong>DST</strong>200B54W15-5 25,0 33,5 1585 1169 54 360 190,5 0,91 0 0,822 37,5 132 3450 2545<br />

300 <strong>DST</strong>200K54W30-5 12,0 16,1 382 282 25,5 345 98 0,9 0 0,868 75 66 890 656<br />

<strong>DST</strong>200M54W30-5 24,5 32,9 780 575 51 350 100 0,9 0 0,883 75 126 1740 1283<br />

<strong>DST</strong>200L54W30-5 36,5 48,9 1162 857 75 355 101,5 0,89 0 0,889 75 186 2600 1918<br />

<strong>DST</strong>200B54W30-5 48,5 65 1544 1139 98 360 103,2 0,89 0 0,895 75 243 3450 2545<br />

450 <strong>DST</strong>200K54W45-5 17,7 23,7 375 277 36,5 345 67,4 0,9 0 0,898 112,5 96 890 656<br />

<strong>DST</strong>200M54W45-5 36,0 48,3 760 561 73 350 68,1 0,89 0 0,91 112,5 186 1740 1283<br />

<strong>DST</strong>200L54W45-5 53,0 71,1 1124 829 113 330 65,7 0,89 0 0,914 112,5 288 2600 1918<br />

<strong>DST</strong>200B54W45-5 71,0 95,2 1506 1111 138 360 70,7 0,89 0 0,92 112,5 353 3450 2545<br />

nN Typ Jmot Jmot Jmot Jmot m m m m<br />

[kgm²] lb ft² [kgm²] lb ft² [kg] lb [kg] lb<br />

min -<br />

1<br />

solid<br />

shaft<br />

hollow<br />

shaft<br />

solid<br />

shaft<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

6 Baumüller Nürnberg GmbH<br />

1<br />

hollow<br />

shaft<br />

150 <strong>DST</strong>200K54W15-5 0,40 9,49 0,44 10,44 199 439 175 386<br />

<strong>DST</strong>200M54W15-5 0,70 16,61 0,74 17,56 270 595 235 518<br />

<strong>DST</strong>200L54W15-5- 1,00 23,73 1,00 23,73 343 756 300 661<br />

<strong>DST</strong>200B54W15-5 1,30 30,85 1,30 30,85 413 911 360 794<br />

300 <strong>DST</strong>200K54W30-5 0,40 9,49 0,44 10,44 199 439 175 386<br />

<strong>DST</strong>200M54W30-5 0,70 16,61 0,74 17,56 270 595 235 518<br />

<strong>DST</strong>200L54W30-5 1,00 23,73 1,00 23,73 343 756 300 661<br />

<strong>DST</strong>200B54W30-5 1,30 30,85 1,30 30,85 413 911 360 794<br />

450 <strong>DST</strong>200K54W45-5 0,40 9,49 0,44 10,44 199 439 175 386<br />

<strong>DST</strong>200M54W45-5 0,70 16,61 0,74 17,56 270 595 235 518<br />

<strong>DST</strong>200L54W45-5 1,00 23,73 1,00 23,73 343 756 300 661<br />

<strong>DST</strong>200B54W45-5 1,30 30,85 1,30 30,85 413 911 360 794<br />

Legend<br />

American units

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

<strong>DST</strong> 260 54 W (IP 54 water-cooled)<br />

Mains voltage 3 AC 400 V for converters with uncontrolled supply<br />

nN Typ PN PN MN MN IN UN KE / COLD cos ϕ IdN ηN fN Io,max Mo,max Mo,max<br />

min -<br />

kW hp Nm lbf ft A V V/100min<br />

1<br />

-<br />

- A - Hz A Nm lbf ft<br />

1<br />

150 <strong>DST</strong>260K54W15-5 20,8 27,9 1325 977 48 360 194,6 0,86 7 0,81 50 106 2450 1807<br />

<strong>DST</strong>260M54W15-5 34,5 46,3 2200 1623 78 355 190 0,84 6 0,86 50 208 4400 3245<br />

<strong>DST</strong>260L54W15-5 48,5 65 3088 2278 108 355 193,4 0,84 11 0,87 50 288 6200 4573<br />

<strong>DST</strong>260B54W15-5 62,5 83,8 3980 2935 138 360 194 0,84 11 0,864 50 370 8000 5900<br />

<strong>DST</strong>260X54W15-5 76 102 4840 3570 165 360 199 0,85 20 0,87 50 440 9750 7191<br />

300 <strong>DST</strong>260K54W30-5 40 53,6 1275 940 87 355 105 0,86 17 0,87 100 196 2450 1807<br />

<strong>DST</strong>260M54W30-5 66 88,5 2100 1549 140 355 103,5 0,848 19 0,9 100 385 4400 3245<br />

<strong>DST</strong>260L54W30-5 94 126 2990 2205 200 355 102,4 0,85 27 0,9 100 545 6200 4573<br />

<strong>DST</strong>260B54W30-5 117 157 3725 2747 240 350 108,2 0,88 56 0,91 100 665 8000 5900<br />

<strong>DST</strong>260X54W30-5 147 197 4680 3452 307 355 103,7 0,85 44 0,92 100 845 9750 7191<br />

450 <strong>DST</strong>260K54W45-5 59 79,1 1250 922 129 360 68,2 0,83 11 0,884 150 302 2450 1807<br />

<strong>DST</strong>260M54W45-5 97 130 2060 1519 206 355 68,8 0,837 20 0,92 150 580 4400 3245<br />

<strong>DST</strong>260L54W45-5 <strong>135</strong> 181 2865 2113 278 355 72 0,87 53 0,91 150 775 6200 4573<br />

<strong>DST</strong>260B54W45-5 170 228 3600 2655 350 360 69,2 0,84 23 0,93 150 1040 8000 5900<br />

nN Typ Jmot Jmot m m<br />

[kgm²] lb ft² [kg] lb<br />

min -<br />

1<br />

solid<br />

shaft<br />

solid<br />

shaft<br />

150 <strong>DST</strong>260K54W15-5 1,4 33,22 364 802<br />

<strong>DST</strong>260M54W15-5 2,1 49,83 477 1052<br />

<strong>DST</strong>260L54W15-5 2,9 68,82 588 1296<br />

<strong>DST</strong>260B54W15-5 3,6 85,43 699 1541<br />

<strong>DST</strong>260X54W15-5 4,4 104,41 811 1788<br />

300 <strong>DST</strong>260K54W30-5 1,4 33,22 364 802<br />

<strong>DST</strong>260M54W30-5 2,1 49,83 477 1052<br />

<strong>DST</strong>260L54W30-5 2,9 68,82 588 1296<br />

<strong>DST</strong>260B54W30-5 3,6 85,43 699 1541<br />

<strong>DST</strong>260X54W30-5 4,4 104,41 811 1788<br />

450 <strong>DST</strong>260K54W45-5 1,4 33,22 364 802<br />

<strong>DST</strong>260M54W45-5 2,1 49,83 477 1052<br />

<strong>DST</strong>260L54W45-5 2,9 68,82 588 1296<br />

<strong>DST</strong>260B54W45-5 3,6 85,43 699 1541<br />

Legend<br />

American units<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 7

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

<strong>DST</strong> <strong>315</strong> 54 W (IP 54 water-cooled)<br />

Mains voltage 3 AC 400 V for converters with uncontrolled supply<br />

nN Typ PN PN MN MN IN UN KE / COLD cos<br />

ϕ<br />

kW hp Nm lbf ft A V V/100min -<br />

- A - Hz A Nm lbf ft<br />

min -<br />

1<br />

IdN ηN fN Io,max Mo,max Mo,max<br />

100 <strong>DST</strong><strong>315</strong>K54W10-5 17 22,8 1628 1201 34,5 360 308 0,93 0 0,854 33,3 87 3750 2766<br />

<strong>DST</strong><strong>315</strong>M54W10-5 29 38,9 2772 2045 60 350 300 0,93 0 0,864 33,3 147 6200 4573<br />

<strong>DST</strong><strong>315</strong>L54W10-5 41 55 3944 2909 83 350 305 0,93 0 0,869 33,3 202 8630 6365<br />

<strong>DST</strong><strong>315</strong>B54W10-5 53 71,1 5064 3735 106 355 309 0,93 0 0,873 33,3 256 11080 8172<br />

<strong>DST</strong><strong>315</strong>X54W10-5 64 85,8 6130 4521 132 345 300 0,93 0 0,876 33,3 322 <strong>135</strong>00 9957<br />

200 <strong>DST</strong><strong>315</strong>K54W20-5 33,5 44,9 1600 1180 65 355 161 0,93 0 0,909 66,7 167 3750 2766<br />

<strong>DST</strong><strong>315</strong>M54W20-5 57 76,4 2725 2010 111 350 161 0,92 0 0,915 66,7 275 6200 4573<br />

<strong>DST</strong><strong>315</strong>L54W20-5 80 107 3820 2817 156 350 161 0,92 0 0,918 66,7 384 8630 6365<br />

<strong>DST</strong><strong>315</strong>B54W20-5 103 138 4920 3629 196 360 163 0,92 0 0,921 66,7 484 11080 8172<br />

<strong>DST</strong><strong>315</strong>X54W20-5 124 166 5920 4366 223 360 174 0,97 36 0,923 66,7 554 <strong>135</strong>00 9957<br />

300 <strong>DST</strong><strong>315</strong>K54W30-5 49 65,7 1560 1151 92 350 111 0,96 9 0,925 100 240 3750 2766<br />

<strong>DST</strong><strong>315</strong>M54W30-5 82 110 2609 1924 150 350 115 0,97 25 0,93 100 385 6200 4573<br />

<strong>DST</strong><strong>315</strong>L54W30-5 118 158 3690 2722 216 360 116 0,92 0 0,933 100 554 8630 6365<br />

<strong>DST</strong><strong>315</strong>B54W30-5 145 194 4620 3408 253 360 122 0,99 60 0,935 100 645 11080 8172<br />

<strong>DST</strong><strong>315</strong>X54W30-5 175 235 5570 4108 303 360 124 0,99 82 0,935 100 780 <strong>135</strong>00 9957<br />

nN Typ Jmot Jmot m m<br />

[kgm²] lb ft² [kg] lb<br />

min -<br />

1<br />

solid<br />

shaft<br />

solid<br />

shaft<br />

100 <strong>DST</strong><strong>315</strong>K54W10-5 3,60 85,43 503 1109<br />

<strong>DST</strong><strong>315</strong>M54W10-5 5,60 132,89 670 1477<br />

<strong>DST</strong><strong>315</strong>L54W10-5 7,60 180,35 775 1709<br />

<strong>DST</strong><strong>315</strong>B54W10-5 9,60 227,81 940 2072<br />

<strong>DST</strong><strong>315</strong>X54W10-5 11,60 275,27 1072 2363<br />

200 <strong>DST</strong><strong>315</strong>K54W20-5 3,60 85,43 503 1109<br />

<strong>DST</strong><strong>315</strong>M54W20-5 5,60 132,89 670 1477<br />

<strong>DST</strong><strong>315</strong>L54W20-5 7,60 180,35 775 1709<br />

<strong>DST</strong><strong>315</strong>B54W20-5 9,60 227,81 940 2072<br />

<strong>DST</strong><strong>315</strong>X54W20-5 11,60 275,27 1072 2363<br />

300 <strong>DST</strong><strong>315</strong>K54W30-5 3,60 85,43 503 1109<br />

<strong>DST</strong><strong>315</strong>M54W30-5 5,60 132,89 670 1477<br />

<strong>DST</strong><strong>315</strong>L54W30-5 7,60 180,35 775 1709<br />

<strong>DST</strong><strong>315</strong>B54W30-5 9,60 227,81 940 2072<br />

<strong>DST</strong><strong>315</strong>X54W30-5 11,60 275,27 1072 2363<br />

Legend<br />

American units<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

8 Baumüller Nürnberg GmbH<br />

1

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Dimension drawing<br />

<strong>DST</strong> <strong>135</strong><br />

Version IM B14 Standard<br />

Zentrierung /<br />

Centering<br />

Type <strong>DST</strong> k k2 q<br />

<strong>DST</strong> <strong>135</strong> K 431 482 304<br />

<strong>DST</strong> <strong>135</strong> M 481 532 354<br />

<strong>DST</strong> <strong>135</strong> L 531 582 404<br />

<strong>DST</strong> <strong>135</strong> B 581 632 454<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 9

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Dimension drawing<br />

<strong>DST</strong> <strong>135</strong> – Hollow shaft version ( ∅hollow shaft 150mm )<br />

Version IM B14<br />

Type <strong>DST</strong> k q<br />

<strong>DST</strong> <strong>135</strong> K 317 212<br />

<strong>DST</strong> <strong>135</strong> M 367 262<br />

<strong>DST</strong> <strong>135</strong> L 417 312<br />

<strong>DST</strong> <strong>135</strong> B 467 362<br />

tief / deep<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

10 Baumüller Nürnberg GmbH

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Dimension drawing<br />

<strong>DST</strong> 200<br />

Version IM B34 Standard<br />

Zentrierung /<br />

Centering<br />

Type <strong>DST</strong> k k2 q a1 p1 y s2 s3<br />

<strong>DST</strong> 200 K 480 530 360 224.5 510 145 Ø40.5 Ø25.5<br />

<strong>DST</strong> 200 M 580 630 425 324.5 535 215 Ø51 Ø25.5<br />

<strong>DST</strong> 200 L 680 730 525 424.5 535 215 Ø51 Ø25.5<br />

<strong>DST</strong> 200 B 780 830 625 524.5 535 215 Ø51 Ø25.5<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 11

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Dimension drawing<br />

<strong>DST</strong> 200– Hollow shaft version ( ∅hollow shaft 150mm )<br />

Version IM B14<br />

Type <strong>DST</strong> k k2 q p1 y s2 s3<br />

<strong>DST</strong> 200 K 275 324 190 510 145 Ø40,5 Ø25,5<br />

<strong>DST</strong> 200 M 375 424 255 535 215 Ø51 Ø25,5<br />

<strong>DST</strong> 200 L 475 524 355 535 215 Ø51 Ø25,5<br />

<strong>DST</strong> 200 B 575 624 455 535 215 Ø51 Ø25,5<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

12 Baumüller Nürnberg GmbH<br />

tief / deep

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Dimension drawing<br />

<strong>DST</strong> 260<br />

Version IM B34 Standard<br />

Zentrierung /<br />

Centering<br />

Type <strong>DST</strong> k k2 q a1 p1 y s2 s3<br />

<strong>DST</strong> 260 K 580 631 432 289 653 215 Ø51 Ø25,5<br />

<strong>DST</strong> 260 M 680 731 512 389 663 255 Ø64 Ø25,5<br />

<strong>DST</strong> 260 L 780 831 612 489 663 255 1) Ø64 Ø25,5<br />

<strong>DST</strong> 260 B 880 931 712 589 663 255 1) Ø64 Ø25,5<br />

<strong>DST</strong> 260 X 980 1031 812 689 663 255 1) Ø64 Ø25,5<br />

1) : at rated current > 269 A terminal box is larger (y = 365).<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 13

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Dimension drawing<br />

<strong>DST</strong> <strong>315</strong><br />

Version IM B34 Standard<br />

Zentrierung /<br />

Centering<br />

Type <strong>DST</strong> k k2 q a1 p1 y s2 s3<br />

<strong>DST</strong> <strong>315</strong> K 600 650 452 301 770 215 Ø51 Ø25.5<br />

<strong>DST</strong> <strong>315</strong> M 700 750 510 401 790 295 Ø64 Ø25.5<br />

<strong>DST</strong> <strong>315</strong> L 800 850 610 501 790 295 Ø64 Ø25.5<br />

<strong>DST</strong> <strong>315</strong> B 900 950 710 601 790 295 Ø64 Ø25.5<br />

<strong>DST</strong> <strong>315</strong> X 1000 1050 810 701 790 295 Ø64 Ø25.5<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

14 Baumüller Nürnberg GmbH

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Dimension drawing<br />

<strong>Three</strong>-<strong>phase</strong> <strong>synchronous</strong> motor<br />

<strong>DST</strong> – kit<br />

Version IM B14 without self-support and without encoder<br />

Type <strong>DST</strong> ØDa k Ødw<br />

Øb1<br />

H7<br />

f1 Øe1 s1 w1 w2 p1 y s2 s3<br />

<strong>DST</strong> <strong>135</strong> K 274 200 150 268 7 252 M8 45° 45° 380 145 Ø40,5 Ø25,5<br />

<strong>DST</strong> <strong>135</strong> M 274 250 150 268 7 252 M8 45° 45° 380 145 Ø40,5 Ø25,5<br />

<strong>DST</strong> <strong>135</strong> L 274 300 150 268 7 252 M8 45° 45° 380 145 Ø40,5 Ø25,5<br />

<strong>DST</strong> <strong>135</strong> B 274 350 150 268 7 252 M8 45° 45° 380 145 Ø40,5 Ø25,5<br />

<strong>DST</strong> 200 K 400 230<br />

<strong>DST</strong> 200 M 400 330<br />

<strong>DST</strong> 200 L 400 430<br />

<strong>DST</strong> 200 B 400 530<br />

1) Ø – Hollow shaft available on request<br />

Rotor and stator connection following technical consultation.<br />

<strong>DST</strong> assembly kit 260 and <strong>315</strong> available on request.<br />

Wasseranschluss /<br />

Water connection<br />

1) 344 7 375 M12 40° 50° 510 145 Ø40,5 Ø25,5<br />

1) 344 7 375 M12 40° 50° 535 215 Ø51 Ø25,5<br />

1) 344 7 375 M12 40° 50° 535 215 Ø51 Ø25,5<br />

1) 344 7 375 M12 40° 50° 535 215 Ø51 Ø25,5<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 15

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Bearings and shaft load<br />

All machines are equipped with rolling-contact bearings. On the solid-shaft version, the non-locating bearing is intended for<br />

the drive end and the locating bearing for the non-drive end. On the hollow-shaft version, it is the other way around.<br />

Ball-bearing assignment for solid-shaft version Ball-bearing assignment for hollow-shaft version<br />

Frame size D-end ND-end Frame size D-end ND-end<br />

<strong>135</strong> 6217 2ZRC3 6217 2ZRC3 <strong>135</strong> 61838 61836<br />

200 6220 2ZRC3 6220 2ZRC3 200 61838 61836<br />

260 6226 2ZRC3 6220 2ZRC3<br />

<strong>315</strong> 6226 2ZRC3 6226 2ZRC3<br />

Determination of radial forces FR<br />

When using pulleys, the radial load is calculated according to the following formula:<br />

PN = Nominal power in kW<br />

F<br />

R<br />

7<br />

2⋅10<br />

⋅P<br />

k<br />

n⋅D<br />

N<br />

= [N]<br />

n = Nominal speed in rpm<br />

D = Pulley diameter in mm<br />

The belt tightening factor k is approximately:<br />

k = 1.8...2.5 for V-belt<br />

k = 2.2..3.5 for flat belt<br />

(Observe specifications of the belt manufacturer)<br />

To ensure safe and reliable <strong>torque</strong> transmission, it is necessary to utilize the entire bearing length of the key. Otherwise, the<br />

key may be subjected to an excessive compressive load per unit area, which in turn can result in the failure of the motor.<br />

The pulley must be mounted up to the shaft shoulder and only tightened to the following maximum tightening <strong>torque</strong>s.<br />

Gland M12 M16 M20 M24<br />

Tightening <strong>torque</strong> 33.0 Nm 80 Nm 160 Nm 255 Nm<br />

Permissible radial forces FR at the shaft end<br />

The ball bearings have been dimensioned for a calculated service life of approx. 20,000 operating hours 1) . The load values<br />

specified below must not be exceeded. The specified permissible radial forces FR are only valid for horizontal mounting of<br />

the motor without additional axial forces. If additional axial forces are involved, please consult the manufacturer.<br />

Axial load on the motor shaft<br />

When mounting clutches, pulleys, etc. onto the motor shaft, no axial forces must be applied! Therefore, use the internal<br />

thread of the shaft end as an assembly aid.<br />

1 ) Average operating temperature < 90°C<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

16 Baumüller Nürnberg GmbH

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Radial force diagrams<br />

Example<br />

n [ 1/min ]<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

A<br />

Kugellager<br />

0<br />

0<br />

0 1000 2000 3000 4000<br />

Fr [ N ]<br />

5000 6000 7000 8000<br />

Explanation of the example<br />

Welle<br />

Kugellager / Ball bearing Rollenlager / Roller bearing Welle / Shaft<br />

B<br />

Rollenlager<br />

Force acting on the end of the shaft end (for force acting on the middle of the shaft end Fr x 1.1)<br />

Shaft end with keyway<br />

Case A – Ball bearing:<br />

The radial force Fr of the application is used to determine the possible maximum speed of the bearing in the<br />

“Ball bearing” characteristic.<br />

Radial force 1100 N => maximum speed 3250 rpm<br />

The maximum transmittable <strong>torque</strong> is based on the “Shaft” characteristic.<br />

Radial force 1100 N => maximum transmittable <strong>torque</strong> 450 Nm<br />

Case B – Roller bearing:<br />

The radial force Fr of the application is used to determine the possible maximum speed of the bearing in the<br />

“Roller bearing” characteristic.<br />

Radial force 4300 N => maximum speed 1500 rpm<br />

The maximum transmittable <strong>torque</strong> is based on the “Shaft” characteristic.<br />

Radial force 4300 N => maximum transmittable <strong>torque</strong> 345 Nm<br />

The roller bearing requires a minimum radial force of 800 N to avoid bearing damage.<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 17<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

M [ Nm ]

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

n in [ 1/min ]<br />

n in [ 1/min ]<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

<strong>DST</strong> <strong>135</strong> - solid shaft<br />

0<br />

0<br />

0 2500 5000 7500<br />

Fr in [ N ]<br />

10000 12500 15000<br />

Kugellager Welle / Shaft<br />

<strong>DST</strong> 200 - solid shaft<br />

0<br />

0<br />

0 2500 5000 7500 10000 12500 15000<br />

Fr in [ N ]<br />

17500 20000 22500 25000 27500 30000<br />

Kugellager Welle / Shaft<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

18 Baumüller Nürnberg GmbH<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

M in [ Nm ]<br />

M in [ Nm ]

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

n in [ 1/min ]<br />

n in [ 1/min ]<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

<strong>DST</strong> 260 - solid shaft<br />

0<br />

0<br />

0 2500 5000 7500 10000 12500 15000 17500 20000 22500 25000 27500 30000 32500 35000 37500 40000 42500 45000<br />

Fr in [ N ]<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

Kugellager Welle / Shaft<br />

<strong>DST</strong> <strong>315</strong> - solid shaft<br />

0<br />

0<br />

0 2500 5000 7500 10000 12500 15000 17500 20000 22500 25000<br />

Fr in [ N ]<br />

27500 30000 32500 35000 37500 40000 42500 45000<br />

Kugellager Welle / Shaft<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 19<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

M in [ Nm ]<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

M in [ Nm ]

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Main connection – Terminal box<br />

U<br />

L1<br />

Reserve<br />

V W<br />

L2 L3<br />

TM +<br />

gelb/ yellow<br />

TM -<br />

schw./black<br />

TM +<br />

gelb/ yellow<br />

TM -<br />

schw./black<br />

Electrical main connection<br />

Terminal marking<br />

Connection diagram<br />

U V W Power connection<br />

K + K - Thermal sensor<br />

The terminal box sizes can vary depending on the nominal motor current. The relationship between current and<br />

bore diameter for glands is illustrated in the following section and connecting bolt dimensions are specified.<br />

EMC glands should be used.<br />

Motor frame size Nominal current<br />

up to<br />

[A]<br />

Cable entry Number of<br />

main connection<br />

terminals<br />

Tightening <strong>torque</strong>s<br />

for<br />

terminals<br />

[Nm]<br />

<strong>135</strong> K…B<br />

200 K<br />

200 M…B<br />

70 1 x M 40 + 1 x M 25 3 x plug-in type -<br />

260 K<br />

<strong>315</strong> K<br />

115 2 x M 50 + 1 x M 25 3 x M 6 3<br />

200 M…B 175 2 x M 50 + 1 x M 25 3 x M 8 6<br />

260 M…X<br />

<strong>315</strong> K<br />

175 2 x M 63 + 1 x M 25 3 x M 8 6<br />

260 KM…X<br />

<strong>315</strong> M…X<br />

269 2 x M 63 + 1 x M 25 3 x M 10 10<br />

260 L…X<br />

<strong>315</strong> M…X<br />

353 2 x M 63 + 1 x M 25 3 x M 12 15.5<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

20 Baumüller Nürnberg GmbH

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Thermal sensor<br />

As standard, the motors are equipped with a thermal sensor in the stator winding. The data is evaluated in the motor<br />

controller. Additional PTCs or thermal sensors can be fitted on request. They are connected through the terminal box.<br />

Widerstand/Resistance (Ohm)<br />

2000<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

KTY84-130<br />

0<br />

-50 0 50 100 150 200<br />

Temperatur/Temperature (°C)<br />

The motor temperature is continuously monitored using the thermal sensor type KTY 84-130.<br />

The above shown resistance results when the sensor is supplied with a measuring current of 2 mA.<br />

Cooling circuit requirements for water-cooled motors<br />

Conditions Unit Value<br />

Maximum permissible system pressure bar 6<br />

Coolant temperature ° C 10 to 35<br />

- For Motor<br />

See diagram<br />

pH value (at 20° C) --- 6.5 to 9<br />

Overall hardness mmol/l 1.43 to 2.5<br />

Chloride - Cl -<br />

mg/l < 200<br />

Sulfate - SO4² -<br />

mg/l < 200<br />

Oil mg/l < 1<br />

Permissible particle size<br />

solid foreign bodies, particles (e.g., sand)<br />

mm < 0.1<br />

- Tmin for the coolant ≥ TAmbient (but max. coolant temperature of 35°C)<br />

- Depending on the relative humidity, the coolant temperature may be<br />

lower than the ambient temperature. The permissible coolant<br />

temperature (see diagram) depends on the relative humidity<br />

(during operation) and the ambient temperature.<br />

Values of 15% to 85% relative atmospheric humidity (non-condensing) are permissible.<br />

For example, ambient temperature 25°C → relative humidity 65%<br />

→ coolant input temperature ≥ 21°C (see diagram).<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 21

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

min. Kühlmitteltemperatur (°C)<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

Min. Kühlmitteltemperatur in Abhängigkeit von der Umgebungstemperatur und -feuchtigkeit<br />

85% rel. Feuchte<br />

75% rel. Feuchte<br />

55% rel. Feuchte<br />

65% rel. Feuchte<br />

45% rel. Feuchte<br />

35% rel. Feuchte<br />

25% rel. Feuchte<br />

10<br />

0 5 10 15 20 25 30 35 40<br />

Umgebungstemperatur (°C)<br />

- The coolant should take the form of clear, clean water that is free of suspended matter.<br />

Details relating to the amounts of coolant required<br />

<strong>DST</strong> frame size <strong>135</strong> 200 260 <strong>315</strong><br />

Flow rate [l/min]<br />

[minimum]<br />

6.5<br />

[5.0]<br />

10<br />

[8.0]<br />

15% rel. Feuchte<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

22 Baumüller Nürnberg GmbH<br />

13<br />

[11]<br />

Pressure drop [bar] / ± 15% 1.7 2.0 1.8 2.0<br />

Temperature rise [K]<br />

[maximum]<br />

7<br />

[9]<br />

8<br />

[10]<br />

11<br />

[13]<br />

15<br />

[13]<br />

11<br />

[13]<br />

Max. coolant pressure [bar] 6 6 6 6<br />

Connection (G internal thread) 2x 1/4“ 2x 3/8“ 2x 1/2“ 2x 1/2“<br />

The flow and pressure rate data consists of tentative values for the maximum shaft output of a frame size.<br />

Reduced values may also be permissible (following consultation), depending on the overall length and coolant<br />

input temperature.<br />

The feed valve can be controlled specifically in accordance with the motor temperature detected with the<br />

KTY84-130.

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Encoder<br />

SINCOS SRS/SRM 50 (SICK|STEGMANN) (Option)<br />

Number of sine, cosine periods per revolution<br />

SRS 50 / SRM 50<br />

1024<br />

Number of increments per revolution 32768<br />

Number of absolute resolved revolutions 1 4096<br />

Code type for the absolute value Binary<br />

Output frequency of sine, cosine signals (kHz) 0 ... 200<br />

Error limits when evaluating 1024 signals, integral nonlinearity<br />

(arc seconds)<br />

+/- 45<br />

Non-linearity within a sine, cosine period; differential nonlinearity<br />

(arc seconds)<br />

+/- 7<br />

Working speed up to which the absolute position can be<br />

formed (1/min)<br />

6000<br />

Maximum operating speed (1/min) 12000<br />

Output signals; 2 x 90° shifted sinusoidal signals (Vpp) 1<br />

Output signal serial RS 485,<br />

a<strong>synchronous</strong>,<br />

halfduplex<br />

Operating voltage range (V) 7 ... 12<br />

Operating current without load (mA) 80<br />

SRS/SRM 50 connection<br />

View to contact side of female connector<br />

Pin Signal<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

ref cos<br />

+ 485<br />

sin<br />

ref sin<br />

- 485<br />

cos<br />

Screening<br />

Gnd<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 23<br />

+ U

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

ECN 1313 EQN 1325 (Heidenhain)<br />

Number of sine, cosine periods per revolution<br />

ECN 1313 / EQN 1325<br />

2048<br />

System accuracy in arc seconds ± 20<br />

Number of absolute resolved revolutions 1 4096 ( 12 bit)<br />

Code type for the absolute value EnDat 2.1<br />

Sampling limit frequency or limit frequency (kHz) 0 ... 200<br />

Position values / revolution 8192 ( 13 bit)<br />

Working speed up to which the absolute position can be<br />

formed (1/min)<br />

12.000<br />

Operating speed (1/min) 12000<br />

Voltage supply (V) 5 V ± 5%<br />

Current consumption without load (mA) ≤ 150 ≤ 250<br />

ECN 1313 EQN 1325 connection<br />

9<br />

8<br />

10<br />

16<br />

7<br />

11<br />

15<br />

12<br />

17<br />

6<br />

1<br />

13<br />

14<br />

View to contact side of female connector<br />

5<br />

2<br />

4<br />

3<br />

Pin Signal<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

24 Baumüller Nürnberg GmbH<br />

Up<br />

0V<br />

Up<br />

Clock<br />

Clock inv.<br />

0V<br />

B+<br />

B-<br />

Data<br />

A+<br />

A-<br />

Data inv.

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Resolver (on request)<br />

Pole pair number 1<br />

Ratio 0.5<br />

Frequency 5 kHz<br />

Nominal input voltage 4V<br />

Active input power for no-load operation 112 mW<br />

Current consumption for no-load operation 40mA<br />

Max. output voltage for no-load operation<br />

Voltage constant<br />

2 V eff<br />

Rotor resistance 44 Ω ± 10%<br />

Stator resistance 28 Ω ± 10%<br />

Rotor impedance for no-load operation 70 + j 74 Ω ± 15%<br />

Rotor impedance at short-circuit 62 + j 66 Ω ± 15%<br />

Stator impedance for no-load operation with min. coupling 108 + j 206 Ω ± 15%<br />

Stator impedance at short-circuit and maximum coupling 97 + j 183 Ω ± 15%<br />

Phase shift 8°<br />

Zero voltage 15 mV<br />

Phase error referred to zero position 10’<br />

Resolver connection<br />

View to contact side of female connector<br />

Pin Signal<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 25<br />

cos -<br />

sin –<br />

sin +<br />

NOTE: We recommend that this only be used when low requirements are made with regard to the true running<br />

characteristics of the motor!<br />

cos +<br />

Ref +<br />

Ref -

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Dimension drawing of encoder connectors<br />

Female connector<br />

Male connector<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

26 Baumüller Nürnberg GmbH

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Encoder cables<br />

General<br />

A fully preassembled encoder cable is used for all encoder systems. The connection on the motor side takes<br />

the form of a 12-pin round signal connector in the case of a resolver and SRS/SRM 50 or a 17-pin round signal<br />

connector in the case of the ECN 1313/EQN 132. The connection on the controller side takes the form of a 15pin<br />

SUB-D connector.<br />

The encoder cables are available in 'trailing' or 'non-trailing' versions. The trailing cable is suitable for use in<br />

trailing chains, for example. In contrast to the 'non-trailing' cable, which has a PVC sheath, the cable sheath for<br />

the trailing version consists of tougher PU for use in environments containing acids and bases (coolants).<br />

Cables can be supplied cut to lengths of complete meters (1 m, 2 m, 10 m) up to a maximum of 10 m. If lengths<br />

in excess of 10 m are required, cables can be supplied cut at 5 m intervals (10 m, 15 m, etc.).<br />

Technical data<br />

1. Technical description – Non-trailing<br />

• LiYCY, 5x (2x0.14mm²) + 2 x 0.5mm² stranded copper, twisted pair<br />

• PVC sheath, gray<br />

• 1 st end: 12- or 17-pin round signal connector with 12 or 17 female contacts<br />

• 2 nd end: 15-pin SUB-D connector with male contacts and locking screws 4-40UNC<br />

• Baumüller labeling, black<br />

• Outer diameter 9.0 mm (+/-3 mm)<br />

• Bending radius: r ≥ 60 mm (fixed installation), r ≥ <strong>135</strong> mm (flexible use)<br />

• Nominal voltage: 250 VAC<br />

2. Technical description – Trailing<br />

• Li12YC11Y, 5x (2x0.14mm²) + 2 x 0.5mm² stranded copper, twisted pair<br />

• PU sheath, black<br />

• 1 st end: 12- or 17-pin round signal connector with 12 or 17 female contacts<br />

• 2 nd end: 15-pin SUB-D connector with male contacts and locking screws 4-40UNC<br />

• Baumüller labeling, white<br />

• Outer diameter 9.0 mm (+/-3 mm)<br />

• Bending radius: r ≥ 70 mm (fixed installation), r ≥ 100 mm (flexible use)<br />

• Nominal voltage: 300 VAC<br />

<strong>DST</strong> <strong>135</strong> - <strong>315</strong> 07/2007 Technical alterations reserved<br />

Baumüller Nürnberg GmbH 27

Synchronous Torque Motor <strong>DST</strong> <strong>135</strong> - <strong>315</strong><br />

Application notes<br />

• Operating temperature<br />

Trailing Non-trailing<br />

Limit temperature At the surface At the surface<br />

No/few movements - 40°C to + 80°C - 30°C to + 80°C<br />

Continuous movements - 30°C to + 80°C - 5°C to + 70°C<br />

• Cable laying at the motor<br />

The cables must not touch the motor surface.<br />

Technical alterations reserved 07/2007 <strong>DST</strong> <strong>135</strong> – <strong>315</strong><br />

28 Baumüller Nürnberg GmbH

Headquarters<br />

Baumüller Nürnberg GmbH<br />

Ostendstraße 80-90, 90482 Nürnberg<br />

T: +49(0)911 5432-0, F: +49(0)911 5432-130<br />

www.baumueller.com<br />

Baumüller Anlagen-Systemtechnik<br />

GmbH & Co. KG<br />

Ostendstraße 84, 90482 Nürnberg<br />

T: +49(0)911 54408-0, F: +49(0)911 54408-769<br />

www.baumueller.com<br />

Baumüller Reparaturwerk GmbH & Co. KG<br />

Andernacher Straße 19, 90411 Nürnberg<br />

T: +49(0)911 9552-0, F: +49(0)911 9552-999<br />

www.baumueller.com<br />

Nürmont Installations GmbH & Co. KG<br />

Am Keuper 14, 90475 Nürnberg<br />

T: +49(0)9128 9255-0, F: +49(0)9128 9255-333<br />

www.nuermont.com<br />

Subsidiaries<br />

Australia<br />

Baumüller Australia Pty. Ltd.<br />

19 Baker Street, Botany NSW 2019, Sydney,<br />

T: +61 2 83350-100, F: +61 2 83350-169<br />

Austria<br />

Baumüller Austria Ges.mbH<br />

Im Bäckerfeld 17, 4060 Leonding<br />

T: +43(0)732 674414-0, F: +43(0)732 674414-32<br />

Brazil<br />

NC Service Indústria e Comércio Ltda.<br />

Av. Tamboré, 1217 Baruerí-SP, 06460-000<br />

T: +55(0)11 4195-0502, F: +55(0)11 4195-2479<br />

China<br />

Baumueller Automation Equipment<br />

Trading (Shanghai) Co. Ltd., Cailun Rd. 88,<br />

Pudong Zhangjiang, 201203 Shanghai,<br />

T: +86(0)21 5855 1533, F: +86(0)21 5855 9487<br />

China<br />

Beijing Yanghai Automation Technology Co., Ltd.<br />

Room 1008, No.7, Huaqing Business Building,<br />

Iluaqing Garden, Wudaokou, Haidian District,<br />

100083 Beijing,<br />

T: +86(0)10 8286 7980, F: +86(0)10 8286 7987<br />

China<br />

Sunary Automatic Technology Limited Company<br />

3rd Floor No.476, Chunxiao Rd., Zhangjiang<br />

High-Tech Park Pudong, Shanghai 201203,<br />

T: +86(0)21 5080 9898, F: +86(0)21 5308 7675<br />

Czech Republic, Slovakia<br />

VAE Prosys s.r.o.<br />

Varsavska 9a, 70900 Ostrava<br />

T: +420 596 616 555, F: +420 596 616 777<br />

Denmark<br />

Robotek EL & Teknik A/S<br />

Blokken 31, Postbox 30, 3460 Birkerød<br />

T: +45 4484 7360, F: +45 4484 4177<br />

Finland<br />

Kontram Oy<br />

Olarinluoma 12, P.O.Box 88, 02201 Espoo<br />

T: +358 9 8866 4500, F: +358 9 8866 4799<br />

France<br />

Baumüller France S.à.r.l.<br />

Zone de la Malnoue 39, Avenue de l´Europe,<br />

77184 Emerainville<br />

T: +33(0)1 6461 6622, F: +33(0)1 6461 6006<br />

France<br />

Baumüller France S.à.r.l. (Strasbourg)<br />

9 rue de la Durance, 67100 Strasbourg<br />

T: +33(0)3 8840 1251, F: +33(0)3 8840 0724<br />

Germany - Darmstadt<br />

Baumüller Nürnberg GmbH<br />

Waldstraße 1, 64347 Griesheim<br />

T: +49(0)6155 8430-00, F: +49(0)6155 8430-20<br />

Germany - Düsseldorf<br />

Baumüller Nürnberg GmbH<br />

Jacob-Kaiser-Str. 7, 47877 Willich-Münchheide<br />

T: +49(0)2154 487-0, F: +49(0)2154 487-59<br />

Germany - Dresden<br />

Baumüller Nürnberg GmbH<br />

Nordstraße 57, 01917 Kamenz<br />

T: +49(0)3578 3406-0, F: +49(0)3578 3406-50<br />

Germany - Freiberg<br />

Nürmont Installations GmbH & Co. KG<br />

Am Junger Löwe Schacht 11, 09599 Freiberg<br />

T: +49(0)3731 3084-0, F: +49(0)3731 3084-33<br />

Germany - Hannover<br />

Baumüller Nürnberg GmbH<br />

Bohlenweg 10, 30853 Langenhagen<br />

T: +49(0)511 771 968-0, F: +49(0)511 771 968-77<br />

Germany - München<br />

Baumüller Reparaturwerk GmbH & Co. KG<br />

Meglingerstraße 58, 81477 München<br />

T: +49(0)89 748 898-0, F: +49(0)89 748 898-55<br />

Germany - Nürnberg<br />

Baumüller Nürnberg GmbH<br />

Ostendstraße 80-90, 90482 Nürnberg<br />

T: +49(0)911 5432-501, F: +49(0)911 5432-510<br />

Germany - Stuttgart<br />

Baumüller Nürnberg GmbH<br />

Im Ghai 12, 73776 Altbach<br />

T: +49(0)7153 61036-0, F: +49(0)7153 61036-29<br />

Germany - Stuttgart<br />

Nürmont Installations GmbH & Co. KG<br />

Im Ghai 12, 73776 Altbach<br />

T: +49(0)7153 92798-0, F: +49(0)7153 92798-99<br />

Great Britain<br />

Baumüller (UK) Ltd.<br />

14 Redlands Centre, Coulsdon,<br />

Surrey CR5 2HT<br />

T: +44(0)208 763-2990, F: +44(0)208 763-2959<br />

India<br />

Baumüller KAT India Pvt. Ltd.<br />

4th Floor, Commerce Avenue, Mahaganesh<br />

Colony, Paud Road, 411038 Pune<br />

T: +91 20 254596 82, F: +91 20 254596 84<br />

Italy<br />

Baumüller Italia S.r.l.,<br />

Viale Italia 12, 20094 Corsico (Mi)<br />

T: +39 02 45100-181, F: +39 02 45100-426<br />

Netherlands<br />

Baumüller Benelux B.V.<br />

Platinastraat 141, 2718 SR Zoetermeer<br />

T: +31(0)79 3614-290, F: +31(0)79 3614-339<br />

Poland<br />

Mekelburger Polska<br />

Ul. Kóscielna 39 F/3, 60537 Poznán,<br />

T: +48(0)61 8481 520, F: +48(0)61 8481 520<br />

Russia, Kazakhstan<br />

Prosensor<br />

Zavadoskaj 1b/2, Moscow, 124365,<br />

T: +7 495 6428 476, F: +7 495 6428 477<br />

Slovenia<br />

Baumüller Dravinja d.o.o.<br />

Delavska cesta 10, 3210 Slovenske-Konjice<br />

T: +386 3 75723-00, F: +386 3 75723-32/33<br />

South Korea<br />

Bomac Systems<br />

712 Yucheon Factophia, 196 Anyang-7 dong,<br />

Mananku, Anyangsi, Kyungkido 430-017,<br />

T: +82 31 467-2030, F: +82 31 467-2033<br />

South Africa<br />

Motion Tronic cc<br />

Unit 18 Wareing Park, 3610 Pinetown<br />

T : +27 31 7011620, F : +27 86 6150597<br />

Spain<br />

Baumüller Ibérica S.A.<br />

c/ Crom, 35-37, 2°2 a ,<br />

08907 Hospitalet de Llobregat<br />

T: +34(0)93 2963 0985, F: +34(0)93 263 2059<br />

Switzerland<br />

Baumüller Suisse S.A.<br />

Rue Galilée 9, 1400 Yverdon-les Bains<br />

T: +41(0)24 420 77-70, F: +41(0)24 420 77-79<br />

Switzerland<br />

Baumüller Schweiz AG (Büro Ost)<br />

Oberwiesenstraße 75, 8500 Frauenfeld<br />

T: +41(0)52 723 28-00, F: +41(0)52 723 28-01<br />

Thailand<br />

Mr. Tom Sale and Service Co., Ltd.<br />

39/9 Moo 1, Tepkanjana Rd., Tambol Nadee<br />

Amphur Muang, 74000 Samutsakorn<br />

T: +66 34 854932-4, F: +66 34 854935<br />

Turkey<br />

Baumüller Motor Kontrol Sistem<br />

San. Ve Tic. Ltd. Sti<br />

Girne Mah., Kücükyali Is Merkezi, B Blok No. 12,<br />

Maltepe, 34852 Maltepe - Istanbul<br />

T: +90(0)216 519-9071, F: +90(0)216 519-9072<br />

USA<br />

Baumueller Inc.<br />

117 West Dudley Town Road,<br />

Bloomfield, CT 06002<br />

T: +1 860-243-0232, F: +1 860-286-3080<br />

USA<br />

Baumueller Inc.<br />

1858 S. Elmhurst Road, Mount Prospect,<br />

IL 60005,<br />

T: +1 847-956-7392, F: +1 847-956-7925<br />

USA<br />

Baumueller-Nuermont Corp.<br />

1858 S. Elmhurst Road, Mount Prospect,<br />

IL 60005,<br />

T: +1 847-956-7392, F: +1 847-956-7925<br />

USA<br />

Baumueller-Nuermont Corp.<br />

2650 Pleasantdale Road, Suite 15,<br />

Doraville, GA 30340<br />

T: +1 678-291-0535, F: +1 678-291-0537<br />

Venezuela, Colombia, Ecuador<br />

Nimbus International C.A.<br />

C.C. Parque Tuy, Local P-18,<br />

Ocumare del Tuy, 1209<br />

T: +58 239 225 1347, F: +58 239 225 7149<br />

Information subject to change

e<br />

3.136.e.12/07.10B<br />

07/07