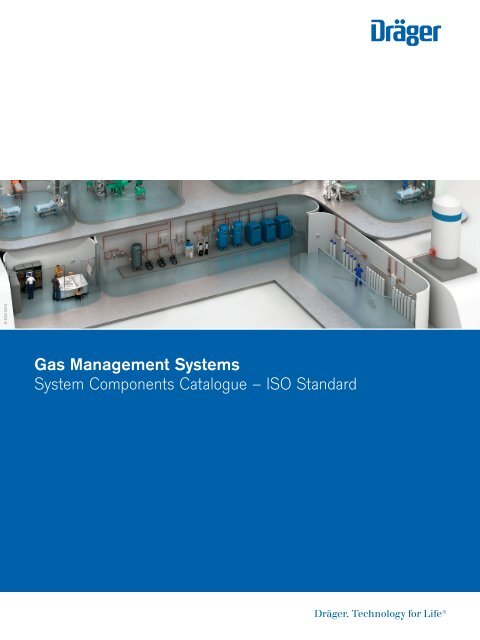

Gas Management Systems System Components Catalogue – ISO Standard

With over 50 years of experience in the planning and manufacturing of medical gas management systems, Dräger is one of the market and technology leaders in Germany as well as in the international market. Our systems, installed and maintained by Dräger installation specialists and DrägerService technicians, offer premium reliability and safety, above-average durability, and meet the highest quality standards. Medical gases (oxygen, compressed air, nitrous oxide, and carbon dioxide) and vacuum must be safely and reliably available at all times. We deliver tailor-made system solutions, so that your hospital always has the correct gas available in the correct quantities and quality. From planning consultation to assembly and subsequent after-sales service, we provide complete services from one source regardless of whether it is a new development, an enlargement or a renovation. Not all articles are available worldwide.

With over 50 years of experience in the planning and manufacturing of medical

gas management systems, Dräger is one of the market and technology leaders

in Germany as well as in the international market.

Our systems, installed and maintained by Dräger installation specialists and

DrägerService technicians, offer premium reliability and safety, above-average

durability, and meet the highest quality standards.

Medical gases (oxygen, compressed air, nitrous oxide, and carbon dioxide) and

vacuum must be safely and reliably available at all times. We deliver tailor-made

system solutions, so that your hospital always has the correct gas available in the

correct quantities and quality. From planning consultation to assembly and

subsequent after-sales service, we provide complete services from one source

regardless of whether it is a new development, an enlargement or a renovation.

Not all articles are available worldwide.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

D-533-2014<br />

<strong>Gas</strong> <strong>Management</strong> <strong><strong>System</strong>s</strong><br />

<strong>System</strong> <strong>Components</strong> <strong>Catalogue</strong> <strong>–</strong> <strong>ISO</strong> <strong>Standard</strong>

02 | GAS MANAGEMENT SYSTEMS

INTRODUCTION | GAS MANAGEMENT SYSTEMS | 03<br />

<strong>Gas</strong> <strong>Management</strong> <strong><strong>System</strong>s</strong><br />

With over 50 years of experience in the planning and manufacturing of medical<br />

gas management systems, Dräger is one of the market and technology leaders<br />

in Germany as well as in the international market.<br />

Our systems, installed and maintained by Dräger installation specialists and<br />

DrägerService technicians, offer premium reliability and safety, above-average<br />

durability, and meet the highest quality standards.<br />

Medical gases (oxygen, compressed air, nitrous oxide, and carbon dioxide) and<br />

vacuum must be safely and reliably available at all times. We deliver tailor-made<br />

system solutions, so that your hospital always has the correct gas available in the<br />

correct quantities and quality. From planning consultation to assembly and<br />

subsequent after-sales service, we provide complete services from one source<br />

regardless of whether it is a new development, an enlargement or a renovation.<br />

Not all articles are available worldwide.

04 | GAS MANAGEMENT SYSTEMS | CONTENT<br />

CONTENT<br />

GAS MANAGEMENT SYSTEMS Overview 06<br />

GAS CONTROL SYSTEMS Introduction 08<br />

GCS Family 09<br />

RS Family 14<br />

High pressure assemblies 15<br />

Line pressure assemblies 21<br />

V.I.E. assemblies and accessories 22<br />

Labels and signs 23<br />

COMPRESSED AIR SYSTEMS Introduction 24<br />

Configuration of a medical compressed air plant 25<br />

Piston Compressors DWSC series 26<br />

Screw Compressors DWLC/DWLS series 30<br />

Piston Compressors DWSRM series 34<br />

Piston Compressors DWSBM series 36<br />

Piston Compressors DWSRD series 38<br />

Control Panels 40<br />

Air Receivers 41<br />

EcoPharm Tower and accessories 42<br />

Refrigeration Dryer 45<br />

Air Filter Stations/Pressure Reducing Stations and accessories 49<br />

Compact Compressed Air Plants DWPP 55<br />

Medical Air Guard 57<br />

VACUUM SYSTEMS Introduction 58<br />

Vacuum Pumps 60<br />

Control Panels 62<br />

Vacuum Tank 64<br />

Accessories for vacuum systems 65<br />

Vacuum Packaged Plants 66<br />

DISTRIBUTION SYSTEMS Introduction 68<br />

Copper Pipes 69<br />

Solder- and Adapter Fittings 71<br />

Soldering Material 73

CONTENT | GAS MANAGEMENT SYSTEMS | 05<br />

CONTENT<br />

Fixing Material 75<br />

Pipeline Labelling 78<br />

HT Pipes 79<br />

Pipeline Valves and Control Units 80<br />

Contact Manometers 81<br />

AREA CONTROL UNITS Introduction 82<br />

ACU Valve Box 83<br />

ACU Equipment 84<br />

ACU VoluCount 86<br />

Switch Gauge 87<br />

TERMINAL UNITS Introduction 88<br />

Terminal Units 89<br />

<strong>Standard</strong>-independent base parts 90<br />

DIN <strong>Gas</strong> Terminal Units 91<br />

Probe for DIN Terminal Units 94<br />

Air-Motor Terminal Units 95<br />

Anaesthetic <strong>Gas</strong> Scavenging Terminal Units 95<br />

International <strong>Standard</strong>s <strong>Gas</strong> Terminal Units 96<br />

Energy Duct <strong>System</strong> 99<br />

Hose <strong>System</strong> 100<br />

ALARM SYSTEMS Introduction 102<br />

Alarm <strong><strong>System</strong>s</strong> 103<br />

Alarm <strong>Management</strong> <strong>System</strong> 104<br />

Emergency and Operation Signals 109<br />

RAIL SYSTEMS 110<br />

INDEX 112

06 | GAS MANAGEMENT SYSTEMS | OVERVIEW<br />

<strong>Gas</strong> <strong>Management</strong> <strong><strong>System</strong>s</strong><br />

Dräger <strong>Gas</strong> <strong>Management</strong> <strong><strong>System</strong>s</strong> (GMS) are designed to manage<br />

the hospital’s gas supply needs. Dräger offers complete gas supply<br />

systems which include all necessary components and distribution<br />

pipelines.<br />

Planning and designing <strong>Gas</strong> <strong>Management</strong><br />

<strong><strong>System</strong>s</strong> for either complete hospitals or<br />

individual areas like a new IC or OR area is<br />

a challenging task. Different international<br />

standards and guidelines provide different<br />

information, require different system<br />

configurations and different approaches to<br />

all the challenges occurring.<br />

Dräger is at your side when it comes to<br />

solving these challenges and optimizing the<br />

system design for the benefit of the hospital.<br />

We have more than 50 years experience in<br />

designing, building and testing <strong>Gas</strong><br />

<strong>Management</strong> <strong><strong>System</strong>s</strong>.<br />

As every project is different and the systems<br />

tailor-made for the hospital, it is difficult to<br />

provide generic planning details. Therefore<br />

we kindly ask you to contact your local<br />

Dräger representative for individual planning<br />

support.<br />

Intelligent solutions<br />

from a single source<br />

MT-0018-2006<br />

<strong>Gas</strong> Terminal Units<br />

GAS TERMINAL UNITS<br />

The locations and quantities of gas terminal<br />

units are essential parts of the planning of<br />

every <strong>Gas</strong> <strong>Management</strong> <strong>System</strong>. Depending<br />

on the clinical procedures and applications,<br />

different gases are required in different hospital<br />

areas and the amount of units provided<br />

needs to match processes and devices used<br />

there. Dräger builds world-renowned gas terminal<br />

units since over 40 years and is offering<br />

outlets according to DIN, British <strong>Standard</strong> and<br />

other international types.<br />

Of course, all this also applies to one of the<br />

central areas in the modern hospital. Medical<br />

gases (oxygen, compressed air, nitrous oxide,<br />

and carbon dioxide) and vacuum must be<br />

safely and reliably available at all times. We<br />

deliver tailor-made system solutions, so that<br />

your hospital always has the correct gas<br />

available in the correct quantities and quality.<br />

From planning consultation to assembly and<br />

subsequent 24-hour service, we provide<br />

complete services from one source regardless<br />

of whether it is a new development, an<br />

enlargement or a renovation. With over 50<br />

years of experience in the planning and<br />

manufacturing of medical gas management<br />

systems, Dräger is one of the market and<br />

technology leaders in Germany as well as in<br />

the international market.<br />

Our systems, respectively set up and<br />

maintained by Dräger installation specialists<br />

and DrägerService technicians, offer premium<br />

reliability and safety, above-average durability,<br />

and meet the highest quality standards.<br />

D-1217-2009<br />

Alarm <strong>Management</strong><br />

ALARM MANAGEMENT SYSTEM<br />

A complex system like a medical <strong>Gas</strong><br />

<strong>Management</strong> <strong>System</strong> requires good operational<br />

management and provides a host of information.<br />

Dräger Alarm <strong>Management</strong> <strong><strong>System</strong>s</strong><br />

consolidate all this information like operational<br />

and emergency alarms. Analogue operational<br />

data (e.g. pressure and flow) can also easily<br />

be integrated. All information can be displayed<br />

where ever required with LED, text or touch<br />

display monitors and connected to integrated<br />

building management systems.<br />

D-16746-2010<br />

Distribution systems<br />

DISTRIBUTION SYSTEM<br />

Medical grade copper tubes according to EN<br />

13348 with defined cleanliness and thorough<br />

testing regime in combination with high quality<br />

installation (e.g. inert gas shielding during<br />

welding) form the backbone of the infrastructure<br />

which ensures that all gases are<br />

available at the required points of use. Proper<br />

system calculation according to Dräger<br />

Design Guidelines and international standards<br />

and comprehensive testing and installation<br />

ensure quality and performance of the overall<br />

system.

OVERVIEW | GAS MANAGEMENT SYSTEMS | 07<br />

AREA CONTROL UNITS<br />

All clinical areas need to be controlled individually<br />

by Area Control Units. This includes<br />

pressure gauges for each gas and alarms for<br />

pressure deviations as well as lock-off valves<br />

and emergency inlet points.<br />

D-507-2014<br />

MT-7526-2004<br />

Reliable monitoring throughout the entire system<br />

MT-5164-2004<br />

MT-5206-2004<br />

D-1216-2009<br />

Vacuum pumps<br />

Compressed air system<br />

Cylinder Manifold for oxygen<br />

VACUUM SYSTEM<br />

Vacuum is indispensable for surgical application<br />

(wound field aspiration) as well as bronchus<br />

suctioning in anaesthesia and intensive<br />

care treatment. Dräger vacuum systems with<br />

triplex or quadruplex pumps fulfill the <strong>ISO</strong><br />

7396-1 and match all requirements in terms of<br />

safety and efficiency.<br />

COMPRESSED AIR SYSTEM<br />

Medical air systems for breathing purpose<br />

(4/5 bar) as well as for surgical tool air (7/8<br />

bar) must fulfill the <strong>ISO</strong> 7396-1, breathing air<br />

must also comply with the European Pharmacopoiea.<br />

Dräger medical air systems combine<br />

proven design, safe operations, and efficient<br />

reliability.<br />

CYLINDER MANIFOLDS<br />

Oxygen, Nitrous Oxyde and Carbon Dioxide<br />

can be supplied by 3-fold cylinder manifolds<br />

or by a liquid oxygen tank (V.I.E.) and a 2-fold<br />

cylinder manifold with a Dräger <strong>Gas</strong> Control<br />

Station as the core of the system.

08 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

GAS CONTROL SYSTEMS<br />

D-16865-2009<br />

D-32427-2011<br />

D-9367-2009<br />

<strong>–</strong> Suitable gases: O 2 , N 2 O, CO 2 , Air,<br />

N 2 , Xe, He and Ar<br />

<strong>–</strong> Flow rates of 35, 80 oder 120 m³/h<br />

<strong>–</strong> GCS Basic with pressure gauge<br />

monitoring<br />

<strong>–</strong> GCS Control with electronic<br />

control unit<br />

<strong>–</strong> Integrated Alarm <strong>Management</strong><br />

<strong>–</strong> Interface to external alarm systems<br />

(e.g. BMS)<br />

<strong>–</strong> In accordance with<br />

DIN EN <strong>ISO</strong> 7396-1<br />

<strong>–</strong> Upgradable platform concept<br />

The <strong>Gas</strong> Control Station (GCS) from Dräger is a complete cylinder manifold<br />

system with solutions for various medical gases, flow rates, control and alarm<br />

functions and equipment.<br />

The <strong>Gas</strong> Control Station (GCS) from Dräger<br />

is a complete facility system with solutions for<br />

various medical gases, flow rates, control and<br />

alarm functions and equipment.<br />

All GCS versions are pneumatically controlled.<br />

Thus even during a possible power failure, the<br />

gas supply remains ensured. The GCS Basic<br />

is equipped for monitoring the system pressures<br />

with contact manometers and the<br />

switch-over valve position can be queried via<br />

the potential free contacts.<br />

The GCS Control is equipped with an electronic<br />

control unit that monitors, analyzes and<br />

displays the active supply side, the system<br />

pressures, the current flow and even the room<br />

temperature in a lighted display and in plain<br />

text.

GAS CONTROL SYSTEMS | GAS MANAGEMENT SYSTEMS | 09<br />

GCS FAMILY<br />

7<br />

8<br />

2<br />

3<br />

5<br />

1<br />

4<br />

D-9368-2009<br />

6<br />

<strong>Gas</strong> Control Station<br />

GAS CONTROL STATIONS <strong>–</strong> CONTROL<br />

Required components<br />

1 <strong>Gas</strong> Control Station GCS<br />

2 High-pressure valve with sinter filter<br />

3 High-pressure collecting pipe<br />

4 High-pressure connecting bend<br />

5 Exhaust valve<br />

6 Cylinder holders<br />

7 Liquid gas tank or reserve manifold connection<br />

8 Distributor block<br />

D-16851-2009<br />

Example of an oxygen supply facility

10 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

GCS FAMILY<br />

GAS CONTROL STATIONS <strong>–</strong> CONTROL<br />

<strong>Gas</strong> Control Stations are for regulation and control of the centralised medical<br />

gas supply from cylinder manifolds or vacuum-insulated evaporators (V.I.E.) in<br />

hospitals.<br />

The GCS Control versions contain an electronic control unit that monitors all<br />

system parameters.<br />

D-444-2014<br />

<strong>Gas</strong> Control Station GCS 1200 Control<br />

<strong>Gas</strong> Control Station GCS 1200 Control<br />

Nominal flow rate<br />

120 Nm³/h<br />

Inlet pressure<br />

max. 200 bar<br />

Operating pressure<br />

4 <strong>–</strong> 5 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

<strong>Gas</strong> Control Station GCS 800 Control<br />

Nominal flow rate<br />

80 Nm³/h<br />

Inlet pressure<br />

max. 200 bar<br />

Operating pressure<br />

4 <strong>–</strong> 5 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42156<br />

G42159<br />

<strong>Gas</strong> Control Station GCS 500 Control<br />

Nominal flow rate<br />

35 Nm³/h<br />

Inlet pressure<br />

max. 200 bar<br />

Operating pressure<br />

4 <strong>–</strong> 5 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42162<br />

ONE-STAGE GAS CONTROL STATION FOR LOOP SYSTEMS<br />

<strong>Gas</strong> Control Station GCS 1200 Control<br />

<strong>Gas</strong> Control Station GCS 1201 Control<br />

Nominal flow rate<br />

120 Nm³/h<br />

Inlet pressure<br />

max. 200 bar<br />

Operating pressure<br />

max. 17 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42164<br />

UPGRADE KITS AND ACCESSORIES<br />

GCS Upgrade 1200<br />

Upgrade-Set to upgrade a GCS 800 to the nominal capacity<br />

of a GCS 1200.<br />

G42570<br />

GCS Alarm <strong>System</strong> Interface<br />

Alarm <strong>System</strong> Interface module (ASI) for the integration of a<br />

<strong>Gas</strong> Control Station into the Dräger Alarm <strong>Management</strong> <strong>System</strong>.<br />

G42153<br />

D-531-2014<br />

Relay Module GCS/ACU<br />

Relay Module GCS/ACU<br />

Relays module for the provision of up to 6 potential-free<br />

relay outputs for pressure high-, or low alarms.<br />

G41742

GAS CONTROL SYSTEMS | GAS MANAGEMENT SYSTEMS | 11<br />

GCS FAMILY<br />

GAS CONTROL STATIONS <strong>–</strong> BASIC<br />

<strong>Gas</strong> Control Stations are for regulation and control of the centralised medical<br />

gas supply from cylinder batteries or vacuum-insulated evaporators (V.I.E.) in<br />

hospitals. The GCS Basic versions monitors the system pressure with pressure<br />

gauges and works without any need of electrical power supply.<br />

5 BAR OPERATING PRESSURE<br />

<strong>Gas</strong> Control Station GCS 1200 Basic 5 bar<br />

<strong>Gas</strong> Control Station GCS 1200 Basic 60/5 bar<br />

Nominal flow rate<br />

120 Nm³/h<br />

Inlet pressure<br />

200 bar/60 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42155<br />

G42182<br />

<strong>Gas</strong> Control Station GCS 1200 Basic<br />

<strong>Gas</strong> Control Station GCS 800 Basic 5 bar<br />

<strong>Gas</strong> Control Station GCS 800 Basic 60/5 bar<br />

Nominal flow rate<br />

80 Nm³/h<br />

Inlet pressure<br />

200 bar/60 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42158<br />

G42183<br />

<strong>Gas</strong> Control Station GCS 500 Basic 5 bar<br />

<strong>Gas</strong> Control Station GCS 500 Basic 60/5 bar<br />

Nominal flow rate<br />

35 Nm³/h<br />

Inlet pressure<br />

200 bar/60 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42161<br />

G42184<br />

4 BAR OPERATING PRESSURE<br />

<strong>Gas</strong> Control Station GCS 1200 Basic 4 bar<br />

<strong>Gas</strong> Control Station GCS 1200 Basic 60/4 bar<br />

Nominal flow rate<br />

120 Nm³/h<br />

Inlet pressure<br />

200 bar/60 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42342<br />

G42345<br />

<strong>Gas</strong> Control Station GCS 800 Basic 4 bar<br />

<strong>Gas</strong> Control Station GCS 800 Basic 60/4 bar<br />

Nominal flow rate<br />

80 Nm³/h<br />

Inlet pressure<br />

200 bar/60 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42341<br />

G42344<br />

<strong>Gas</strong> Control Station GCS 500 Basic 4 bar<br />

<strong>Gas</strong> Control Station GCS 500 Basic 60/4 bar<br />

Nominal flow rate<br />

35 Nm³/h<br />

Inlet pressure<br />

200 bar/60 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

G42340<br />

G42343<br />

UPGRADE KITS AND ACCESSORIES<br />

GCS Upgrade 1200<br />

G42570<br />

Upgrade-Set to upgrade a GCS 800 to the nominal capacity of a GCS 1200.<br />

GCS Upgrade Control<br />

Upgrade Set from Basic to Control.<br />

G42176

12 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

GCS FAMILY<br />

TECHNICAL DATA GAS CONTROL STATIONS <strong>–</strong> CONTROL<br />

Product GCS 1200 Control GCS 800 Control GCS 500 Control GCS 1201 Control<br />

Available versions<br />

(Order no.) G42156 G42159 G42162 G42164<br />

Nominal flow rate 120 Nm³/h 80 Nm³/h 35 Nm³/h 120 Nm³/h<br />

High inlet pressure 40 <strong>–</strong> 200 bar 40 <strong>–</strong> 200 bar 40 <strong>–</strong> 200 bar 40 <strong>–</strong> 200 bar<br />

Operating pressure 4 <strong>–</strong> 5 bar 4 <strong>–</strong> 5 bar 4 <strong>–</strong> 5 bar max. 17 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

HP connections<br />

G¾"<br />

Power supply<br />

100 <strong>–</strong> 240 V AC<br />

Alarm interface<br />

Dräger Alarm <strong>Management</strong> <strong>System</strong><br />

Operating temperature 0 <strong>–</strong> 50°C<br />

Dimensions (W×H×D)<br />

550 × 1020 × 195 mm<br />

Switching current<br />

5 mA to 1A<br />

Switching voltage<br />

1.5 to 50 V AC/DC<br />

TECHNICAL DATA GAS CONTROL STATIONS <strong>–</strong> BASIC<br />

Product GCS 1200 Basic GCS 800 Basic GCS 500 Basic<br />

Available versions<br />

(Order no.)<br />

GCS Basic G42155 G42158 G42161<br />

GCS Basic 60 bar G42182 G42183 G42184<br />

GCS Basic - 4 bar G42342 G42341 G42340<br />

GCS Basic 60 bar - 4 bar G42345 G42344 G42343<br />

Nominal flow rate 120 Nm³/h 80 Nm³/h 35 Nm³/h<br />

High inlet pressure 40 <strong>–</strong> 200 bar 40 <strong>–</strong> 200 bar 40 <strong>–</strong> 200 bar<br />

Operating pressure 4/5 bar 4/5 bar 4/5 bar<br />

V.I.E. pressure<br />

13.5 <strong>–</strong> 16.5 bar<br />

HP connections<br />

G¾"<br />

Operating temperature 0 <strong>–</strong> 50 °C<br />

Dimensions (W×H×D)<br />

550 × 1020 × 195 mm<br />

Switching current<br />

5 to 100 mA<br />

Switching voltage 1.5 to 24 V AC/DC 1.5 to 24 V AC/DC 1.5 to 25 V AC/DC

GAS CONTROL SYSTEMS | GAS MANAGEMENT SYSTEMS | 13<br />

GCS FAMILY<br />

ONE-SIDED RESERVE CYLINDER MANIFOLDS<br />

REDUCING UNITS RE1200/500<br />

One-stage reducing unit for the reduction and control of the source pressure<br />

of onesided cylinder manifold systems. Reducing Units are used for emergency/<br />

reserve manifolds feeding into the medium pressure section of <strong>Gas</strong> Control<br />

Stations or Reducing Stations.<br />

CONTROL VERSION FOR INLET PRESSURE 60 AND 200 BAR<br />

Reducing Unit RE 1200 Control<br />

Nominal flow rate<br />

Operating pressure<br />

120 Nm³/h<br />

14 ± 0.5 bar<br />

G42130<br />

Reducing Unit RE 1200 Control<br />

Reducing Unit RE 500 Control<br />

Nominal flow rate<br />

Operating pressure<br />

120 Nm³/h<br />

14 ± 0.5 bar<br />

G42132<br />

BASIC VERSION FOR INLET PRESSURE 200 BAR<br />

Reducing Unit RE 1200 Basic<br />

Nominal flow rate<br />

Operating pressure<br />

120 Nm³/h<br />

14 ± 0.5 bar<br />

G42131<br />

Reducing Unit RE 500 Basic<br />

Nominal flow rate<br />

Operating pressure<br />

35 Nm³/h<br />

14 ± 0.5 bar<br />

G42133<br />

BASIC VERSION FOR INLET PRESSURE MAX 60 BAR<br />

RE 1200 Basic<br />

Reducing Unit RE 1200 Basic <strong>–</strong> 60 bar<br />

Nominal flow rate<br />

120 Nm³/h<br />

Operating pressure<br />

14 ± 0.5 bar<br />

G42185<br />

Reducing Unit RE 500 Basic <strong>–</strong> 60 bar<br />

Nominal flow rate<br />

35 Nm³/h<br />

Operating pressure<br />

14 ± 0.5 bar<br />

G42186<br />

RE 500 Control<br />

RE 500 Basic

14 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

RS FAMILY<br />

TWO-SIDED CYLINDER MANIFOLD SYSTEM<br />

REDUCING STATION RS20<br />

Reducing station for 2-sided cylinder manifold systems with fully automatic<br />

switchover of cylinder manifold sides.<br />

APPLICABLE GASES: OXYGEN<br />

Reducing Station RS 20-O 2<br />

Nominal flow rate<br />

Inlet pressure<br />

Operating pressure<br />

20 Nm³/h<br />

max. 200 bar<br />

5 bar<br />

G40990<br />

Cylinder Manifold RS 20<br />

Redundant second stage pressure reducer for RS20<br />

EN-Set O 2<br />

G41349<br />

APPLICABLE GASES: AIR/N 2 O/CO 2<br />

Reducing Station RS 20-NB<br />

Nominal flow rate<br />

Inlet pressure<br />

Operating pressure<br />

20 Nm³/h<br />

max. 200 bar<br />

5 bar<br />

G40991<br />

Redundant second stage pressure reducer for RS20<br />

EN-Set NB<br />

G41350<br />

CONTROL UNITS<br />

Consisting of:<br />

<strong>–</strong> NIST emergency inlet point<br />

<strong>–</strong> Switching gauge<br />

<strong>–</strong> Safty valve<br />

EN-Set<br />

Control Unit O 2 G41636<br />

Control Unit AIR<br />

G41635<br />

Control Unit N 2 O<br />

G41637<br />

Control Unit CO 2<br />

G41638<br />

Control Unit

GAS CONTROL SYSTEMS | GAS MANAGEMENT SYSTEMS | 15<br />

HIGH PRESSURE ASSEMBLIES<br />

COMMON MOUNTINGS<br />

HP VALVES<br />

HP Valves for shutting off and release of high pressure fittings<br />

HP Valve with Sinter Metal Filter<br />

Spare Sinter Metal Filter insert<br />

O-Ring for HP Sinter Metal Filter<br />

Operating pressure<br />

Connection thread<br />

max. 200 bar<br />

G¾<br />

G40603<br />

T04550<br />

V03854<br />

HP Valve with HP Sinter Metal Filter for shutting off and protection against<br />

contamination for cylinder manifolds.<br />

HP Valves<br />

HP Relief Valve<br />

High pressure relief valve for connection to end of collecting pipe, with soldered<br />

socket to release gases to open air. Flameproof by BAM, oil- and grease free<br />

acc. UVV-Sauerstoff (German safety regulations for oxygen), made of brass with<br />

gasket, for operating pressure of max. 200 bar.<br />

HP Relief Valve O 2 , N 2 O, CO 2<br />

Weight<br />

0.7 kg<br />

V06770<br />

HP Intermediate Valve<br />

High pressure intermediate valve DN 5, to be fitted between connecting bend<br />

and collecting pipe 1-fold, made of brass with gasket, for operating pressure<br />

of max. 200 bar. Flameproof by BAM (Federal Institute for Material Research<br />

and Testing), oil and grease free acc. UVV-Sauerstoff (German safety<br />

regulations for oxygen).<br />

HP Intermediate Valve<br />

Weight<br />

0.7 kg<br />

V07688<br />

HP Relief Valve<br />

HP Shut-off Valve<br />

High pressure shut-off valve DN 10, to be fitted between pressure reducer<br />

station and sinter metal, to shut-off sides of cylinder manifolds, made of brass<br />

with gaskets, for operating pressure of max. 200 bar. Flameproof by BAM,<br />

oil- and grease free acc. UVV-Sauerstoff (German safety regulations for oxygen).<br />

HP Shut-Off Valve DN 10<br />

Weight<br />

0.99 kg<br />

V09041<br />

HP Intermediate Valve<br />

HP Shut-off Valve<br />

HP Sinter Metal Filter<br />

High pressure sinter metal filter DN 10 for protection of pressure reducer<br />

station against pollution, especially for cylinder manifolds with one cylinder,<br />

for operating pressure of 250 bar, filter pores 50 μm, oil- and grease free<br />

acc. UVV-Sauerstoff (German safety regulations for oxygen).<br />

HP Sinter Metal Filter<br />

Weight<br />

1.3 kg<br />

Spare Sinter Metal Filter insert (for V038550)<br />

V03850<br />

T04550<br />

HP Shut-Off Valve and HP Sinter Metal Filter as separate units for shutting off<br />

and protection against pollution for the high pressure pipes.<br />

HP Sinter Metal Filter

16 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

HIGH PRESSURE ASSEMBLIES<br />

COMMON MOUNTINGS<br />

HP COLLECTING PIPES<br />

High pressure collecting pipes for the connection of cylinders with the Dräger<br />

<strong>Gas</strong> Control Stations and RS 20.<br />

HP Collecting Pipe 1-fold<br />

HP Collecting Pipe 1-fold with integrated non-return valve<br />

Collecting Pipe 1-fold/NRV<br />

Operating pressure<br />

max. 200 bar<br />

V06766<br />

HP Collecting Pipes 2-fold/3-fold with integrated non-return valves<br />

Collecting Pipe 2-fold-left/NRV<br />

G40774<br />

Collecting Pipe 2-fold-right/NRV<br />

G40775<br />

Collecting Pipe 3-fold-left/NRV<br />

G40776<br />

Collecting Pipe 3-fold-right/NRV<br />

G40777<br />

Operating pressure<br />

max. 200 bar<br />

HP Collecting Pipe 2-fold<br />

HP Collecting Pipe 3-fold

GAS CONTROL SYSTEMS | GAS MANAGEMENT SYSTEMS | 17<br />

HIGH PRESSURE ASSEMBLIES<br />

COMMON MOUNTINGS<br />

HP T-Piece for the connection of contactors and gauges to the<br />

HP Collecting Pipe.<br />

HP T-Piece<br />

Operating pressure<br />

max. 200 bar<br />

V03005<br />

High pressure bend for the arrangement of a cylinder manifold side<br />

at a right angle.<br />

Pipe Bend 480 × 120 mm<br />

Operating pressure<br />

max. 200 bar<br />

V03124<br />

HP T-Piece<br />

HP GAUGE SETS<br />

HP Pressure gauge to monitor the pressure of a cylinder manifold.<br />

HP Manometer Set 200 bar, left<br />

HP Manometer Set 200 bar, right<br />

HP Manometer Set 60 bar, left<br />

HP Manometer Set 60 bar, right<br />

G42280<br />

G42281<br />

G42282<br />

G42283<br />

HP Pipe Bend<br />

High pressure gauge sets to control the source pressure of one cylinder<br />

manifold side.<br />

Individual Cylinder Pressure Display 200 bar<br />

Individual Cylinder Pressure Display 60 bar<br />

G42291<br />

G42297<br />

High pressure gauge sets to control the source pressure of each<br />

cylinder of the cylinder manifold.<br />

HP Gauge Set<br />

Individual Cylinder Pressure Display

18 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

HIGH PRESSURE ASSEMBLIES<br />

COMMON MOUNTINGS<br />

HP CONNECTING BENDS<br />

HP Connecting bends to connect gas cylinder and collecting pipe rsp.<br />

intermediate or non-return valve.<br />

HP Connecting Bends<br />

Connecting Bend DIN 477-1<br />

Connecting Bend O 2 ,<br />

G¾ (Screwcap) DIN 477-1 Nr. 9<br />

Connecting Bend AIR,<br />

G⅝ DIN 477-1 Nr. 13<br />

Connecting Bend N 2 O,<br />

G⅜ (Screwcap) DIN 477-1 Nr. 11<br />

Connecting Bend CO 2 ,<br />

W 21.8 × 1/14'' (Screwcap) DIN 477-1 Nr. 6<br />

G42426<br />

G42423<br />

G42429<br />

G42432<br />

Connecting Bend NEN 3268<br />

Connecting Bend O 2 ,<br />

G⅝ NEN 3268 RI 2<br />

Connecting Bend AIR,<br />

W 28.806 × 1/14 (Screwcap) NEN 3268 RU 6<br />

Connecting Bend N 2 O,<br />

W 21.8 × 1/14'' (Screwcap) NEN 3268 RU 2<br />

Connecting Bend CO 2 ,<br />

W 21.8 × 1/14'' (Screwcap) NEN 3268 RU 2<br />

G42420<br />

G42419<br />

G42421<br />

G42422<br />

Connecting Bend PIN-Index<br />

Connecting Bend O 2 ,<br />

Pin-Index-<strong>System</strong> EN <strong>ISO</strong> 407 - 7.3.1<br />

Connecting Bend AIR,<br />

Pin-Index-<strong>System</strong> EN <strong>ISO</strong> 407 - 7.3.9<br />

Connecting Bend N 2 O,<br />

Pin-Index-<strong>System</strong> EN <strong>ISO</strong> 407 - 7.3.5<br />

Connecting Bend CO 2 ,<br />

Pin-Index-<strong>System</strong> EN <strong>ISO</strong> 407 - 7.3.8<br />

Connecting Bend Entonox <strong>ISO</strong> 407,<br />

Pin-Index-<strong>System</strong> EN <strong>ISO</strong> 407 - 7.2<br />

G42416<br />

G42415<br />

G42417<br />

G42418<br />

G42479<br />

Connecting Bend BS 341<br />

Connecting Bend O 2 ,<br />

G⅝ BS 341 Nr. 3<br />

Connecting Bend AIR,<br />

G⅝ BS 341 Nr. 3<br />

Connecting Bend N 2 O,<br />

11/16'' 20 TPI (Screwcap) BS 341 Nr. 13<br />

Connecting Bend CO 2 ,<br />

0.860'' × 14 TPl (Screwcap) BS 341 Nr. 8<br />

G42470<br />

G42467<br />

G42473<br />

G42476<br />

Connecting Bend US-CGA<br />

Connecting Bend O 2 ,<br />

.908-14 NGO-RH-INT (Screwcap) CGA 540 G42458<br />

Connecting Bend AIR,<br />

.830-14 NGO-RH-INT (Screwcap) CGA 346 G42455<br />

Connecting Bend N 2 O,<br />

.830-14 NGO-RH-INT (Screwcap) CGA 326 G42461<br />

Connecting Bend CO 2 ,<br />

.830-14 NGO-RH-INT (Screwcap) CGA 320 G42464

GAS CONTROL SYSTEMS | GAS MANAGEMENT SYSTEMS | 19<br />

HIGH PRESSURE ASSEMBLIES<br />

COMMON MOUNTINGS<br />

HP DOUBLE CONNECTING BENDS<br />

HP Double connecting bends for the connection between gas manifold and<br />

collecting pipe rsp. intermediate-, and non-return valve.<br />

HP Double Connecting Bends<br />

Double Connecting Bend DIN 477-1 Left Right<br />

Double Connecting Bend O 2 ,<br />

G¾ (Screwcap) DIN 477-1 Nr. 9 G42427 G42428<br />

Double Connecting Bend AIR,<br />

G⅝ DIN 477-1 Nr. 13 G42424 G42425<br />

Double Connecting Bend N 2 O,<br />

G⅜ (Screwcap) DIN 477-1 Nr. 11 G42430 G42431<br />

Double Connecting Bend CO 2 ,<br />

W 21.8 × 1/14'' (Screwcap) DIN 477-1 Nr. 6 G42433 G42434<br />

Double Connecting Bend PIN-Index Left Right<br />

Double Connecting Bend O 2 ,<br />

Pin-Index-<strong>System</strong> EN <strong>ISO</strong> 407 - 7.3.1 G42436 G42437<br />

Double Connecting Bend Entonox <strong>ISO</strong> 407,<br />

Pin-Index-<strong>System</strong> EN <strong>ISO</strong> 407 - 7.2 G42480 G42481<br />

Double Connecting Bend BS 341 Left Right<br />

Double Connecting Bend O 2 ,<br />

G⅝ BS 341 Nr. 3 G42471 G42472<br />

Double Connecting Bend AIR,<br />

G⅝ BS 341 Nr. 3 G42468 G42469<br />

Double Connecting Bend N 2 O,<br />

11/16'' 20 TPI (Screwcap) BS 341 Nr. 13 G42474 G42475<br />

Double Connecting Bend CO 2 ,<br />

0.860'' × 14 TPl (Screwcap) BS 341 Nr. 8 G42477 G42478<br />

Double Connecting Bend US-CGA Left Right<br />

Double Connecting Bend O 2 ,<br />

.908-14 NGO-RH-INT (Screwcap) CGA 540 G42459 G42460<br />

Double Connecting Bend AIR,<br />

.830-14 NGO-RH-INT (Screwcap) CGA 346 G42456 G42457<br />

Double Connecting Bend N 2 O,<br />

.830-14 NGO-RH-INT (Screwcap) CGA 326 G42462 G42463<br />

Double Connecting Bend CO 2 ,<br />

.830-14 NGO-RH-INT (Screwcap) CGA 320 G42465 G42466

20 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

HIGH PRESSURE ASSEMBLIES<br />

COMMON MOUNTINGS<br />

CYLINDER BRACKET<br />

Made of zinc-plated, angle steel and zinc plated fixing chains incl. fixing<br />

materials. Suitable for 40 ltr. steel cylinders (Ø 204 mm) and 50 ltr. steel<br />

cylinders (Ø 229 mm).<br />

Cylinder Bracket<br />

Cylinder Bracket 1-fold<br />

Weight, 1 cylinder<br />

Length<br />

1.40 kg<br />

310 L (mm)<br />

V11041<br />

Cylinder Bracket 2-fold<br />

Weight, 2 cylinders<br />

Length<br />

2.10 kg<br />

590 L (mm)<br />

V11042<br />

Cylinder Bracket 3-fold<br />

Weight, 3 cylinders<br />

Length<br />

2.90 kg<br />

870 L (mm)<br />

V11043<br />

Supplementary fixing chain<br />

SUPPLEMENTARY FIXING CHAIN<br />

When cylinders are arranged in double rows, this requires one supplementary<br />

fixing chain per cylinder in addition to the cylinder bracket. Chain zinc plated.<br />

Supplementary fixing chain<br />

Weight<br />

0.50 kg<br />

V11038

GAS CONTROL SYSTEMS | GAS MANAGEMENT SYSTEMS | 21<br />

LINE PRESSURE ASSEMBLIES<br />

REDUCING STATION 2. STAGE<br />

REDUCING STATION RS80/2<br />

Pressure reducing station to reduce the main ring pressure to a constant<br />

operating pressue of 5 resp. 8 bar.<br />

Reducing Station RS 80/2<br />

APPLICABLE GASES: OXYGEN<br />

Reducing Station RS 80/2 O 2 <strong>–</strong> 5 bar<br />

Valve Set DN 20-O 2<br />

Valve Set for the equipment of the RS80/2 distributor block<br />

for further ports.<br />

G41280<br />

G41273<br />

APPLICABLE GASES: AIR/N 2 O<br />

Reducing Station RS 80/2 AIR <strong>–</strong> 5 bar<br />

Reducing Station RS 80/2 N 2 O <strong>–</strong> 5 bar<br />

Reducing Station RS 80/2 AIR <strong>–</strong> 8 bar<br />

G41282<br />

G41281<br />

G41283<br />

Valve Set DN 20-NB<br />

Valve Set for the equipment of the RS80/2 distributor block<br />

for further ports.<br />

G41279<br />

MT-4468-2005<br />

Distributor Block 3-fold<br />

COMMON MOUNTINGS<br />

DISTRIBUTOR BLOCK 3-FOLD<br />

Distributor block for the connection with the <strong>Gas</strong> Control Stations and<br />

Reducing Station to distribute the gas to the hospital areas, consisting<br />

of one ball valve and one gauge per port.<br />

Distributor Block 3-fold/Oxygen/non-flammable gases<br />

G40580<br />

SAFETY VALVE 80/5<br />

Safety Valve Set with non-return valve to limit pressure of pipeline systems<br />

with a nominal pressure of 4 -5 bar Relief capacity 80 Nm³/h.<br />

Safety Valve Set 80/5<br />

Pressure Limitation Valve<br />

G42368<br />

G42715<br />

Distributor Block 3-fold<br />

EMERGENCY INLET<br />

Inlet with NIST connector to keep up an emergency gas supply in case of repair<br />

and maintenance work at the main supply.<br />

For continuous gas supply during repair and maintenance work of main supply,<br />

consisting of a gas-type specific NIST connector, provided with metallic screw<br />

cap against pollution and integrated non-return valve, equipped with clamping<br />

ring connection for copper pipe 15 mm on the outlet side.<br />

Safety Valve Set 80/5<br />

Emergency Inlet<br />

Emergency Inlet O 2<br />

Emergency Inlet N 2 O<br />

Emergency Inlet CO 2<br />

Emergency Inlet AIR<br />

G41642<br />

G41643<br />

G41644<br />

G41645

22 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

V.I.E. ASSEMBLIES AND ACCESSORIES<br />

COMMON MOUNTINGS<br />

LIQUID GAS TANK CONNECTION<br />

Connection set for the feeding of gases from vacuum-insulated evaporators<br />

(V.I.E.) into the medium pressure system of the <strong>Gas</strong> Control Stations and<br />

1<br />

2<br />

3<br />

loop systems.<br />

Liquid gas tank connection (complete assembly)<br />

1<br />

1 V.I.E. Control Unit<br />

G41025<br />

V.I.E. control unit for direct V.I.E. feeding into loop system with downstream<br />

Reducing Stations (2nd stages RS 80/2) as well as two-sided cylinder manifold<br />

for reserve supply.<br />

Control Unit set consisting of<br />

<strong>–</strong> ball valve DN 25<br />

<strong>–</strong> gauge, nominal size 50, pressure range 0 <strong>–</strong> 25 bar<br />

<strong>–</strong> non-return valve DN 25<br />

<strong>–</strong> complete assembled with soldering unions<br />

for copper pipe connections 28 × 1.5.<br />

V.I.E. Control Unit<br />

2<br />

2 V.I.E. Connection Set<br />

G40594<br />

Connection set for the feeding of gases from cryogenic gassources (V.I.E.)<br />

into the medium pressure system of the <strong>Gas</strong> Control Stations. Free of oil<br />

and grease acc. UVV-Sauerstoff (German safety regulations for oxygen)<br />

resp. DIN EN <strong>ISO</strong> 7376-1, suitable for oxygen and non-burnable and<br />

non-corrosive gases. Material brass/copper.<br />

Connection set consisting of<br />

<strong>–</strong> 2 soldering unions for copper pipe connection 22 × 1 mm<br />

<strong>–</strong> 1 sinter metal filter with pores 50 μm<br />

<strong>–</strong> 1 non-return valve DN 20<br />

<strong>–</strong> 1 ball valve DN 20<br />

V.I.E. Connection Set<br />

3<br />

3 V.I.E. Pressure Reducer Set<br />

G40834<br />

For connection of <strong>Gas</strong> Control Stations and Reducing Stations with cryogenic<br />

gas pressures > 18 bar. Brass pressure reducer acc. to <strong>ISO</strong> 10524-2 in oil- and<br />

grease free version acc. to UVV-Sauerstoff, flameproof by BAM, for use of<br />

oxygen. Nominal Flow 120 Nm³/h.<br />

Pressure Reducer set consisting of<br />

<strong>–</strong> elastomer diaphragm<br />

<strong>–</strong> gauges for inlet and outlet pressure<br />

<strong>–</strong> soldered screw connections for copper pipe 22 × 1 mm<br />

<strong>–</strong> steel bracket for wall mounting, zinc plated.<br />

V.I.E. Pressure Reducer Set<br />

Switch Gauge 17/13<br />

G42316<br />

Switch gauge for monitoring decreasing and increasing line pressure of<br />

cryogenic gas source.<br />

Switching Points: High: 17 bar<br />

Low: 13 bar<br />

Nominal size 50<br />

Gauge Connection Set 22-G¼<br />

G41405

GAS CONTROL SYSTEMS | GAS MANAGEMENT SYSTEMS | 23<br />

LABELS AND SIGNS<br />

Lachgas<br />

Nitrous O xide<br />

2<br />

LABELS<br />

LABEL CYLINDER MANIFOLD<br />

Labels for room doors and the identification of cylinder manifolds.<br />

Labels<br />

Stickstoff<br />

Nitrogen<br />

N 2<br />

Ko hlensäure<br />

Carbon Dioxide<br />

CO 2<br />

Label "Oxygen Plant/Sauerstoffanlage"<br />

G41656<br />

Label "Nitrous Oxide/Lachgas"<br />

V03743<br />

Label "Nitrogen/Stickstoff"<br />

V03760<br />

Label "Carbon Dioxide/Kohlensäure" V03744<br />

Label "Voll/Full"<br />

V02691<br />

Label "Leer/Empty"<br />

V02692<br />

Label "In Operation/In Betrieb"<br />

V02693<br />

Label "Pressure <strong>Gas</strong> Plants/Druckgasanlagen"<br />

G40951<br />

Label "Entrance for unauthorized personnell strictly forbidden/<br />

Unbefugten Zutritt verboten "<br />

G40952<br />

Label "Danger of Explosion/Explosionsgefahr"<br />

G40953<br />

VOLL<br />

FULL<br />

In B etrieb<br />

In Operation<br />

Unbefugten ist der Zutritt<br />

strengstens v erboten<br />

Entrance for unauthorized<br />

perso nnel strictly prohibited<br />

LEER<br />

EMPTY<br />

Ex plos ions gefahr !<br />

R auchen,offenes Licht und F euer verboten<br />

Funkenbildung vermeiden<br />

Ex plosion hazard !<br />

Smoking, naked flame and fire prohibited.<br />

Avoid sparking.<br />

CYLINDER PRESSURE REDUCER<br />

CYLINDER PRESSURE REDUCER SETS DIN 477-1<br />

Cylinder pressure reducer sets to keep up an emergency gas supply in case of<br />

maintenance at the main supply.<br />

Technical description:<br />

Pressure reducer acc. DIN EN <strong>ISO</strong> 10524-2 in oil- and grease<br />

free version, flameproofed by BAM, with gauges for inlet and<br />

outlet pressure, class 2.5, gas type specific inlet connection,<br />

2 m connection hose DN 6.3, color neutral, with gas type specific NIST<br />

connector, incl. bracket for wall mounting.<br />

Cylinder Pressure Reducer Set O 2<br />

G41419<br />

Cylinder Pressure Reducer Set N 2 O<br />

G41420<br />

Cylinder Pressure Reducer Set AIR<br />

G41421<br />

Cylinder Pressure Reducer Set CO 2<br />

G41422<br />

Weight<br />

0.55 kg<br />

Cylinder valve thread O 2 G¾<br />

N 2 O G⅜<br />

AIR G⅝<br />

CO 2 W 21.8 × 1/14<br />

Max. flow of gas (P P 11 bar/P S 5 bar) 20 m³/h<br />

Inlet pressure (max.) O 2 /AIR 200 bar<br />

N 2 O/CO 2 60 bar<br />

Cylinder Pressure Reducer Set

24 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

COMPRESSED AIR SYSTEMS<br />

MT-8748-2006<br />

MT-5145-2004<br />

Whether for normal care, the ICU, the ER or the OR, medical gas supply is of<br />

major importance for almost every area of the hospital. Central compressed air<br />

systems ensure the continuous supply of medical compressed air of proper<br />

quality and pressure.<br />

D-105958-2013<br />

Dräger has been building central compressed<br />

air supply systems for hospitals, clinics, and<br />

medical practices for over fifty years. Today's<br />

systems meet all the current standards, in particular<br />

DIN EN <strong>ISO</strong> 7396-1, with air quality in<br />

accordance with the European Pharmacopoeia.<br />

After manufacture, every system is<br />

carefully inspected and labeled with a CE certificate<br />

on release. EcoPharm Tower systems,<br />

extremely effective compressed air purification<br />

systems with five filtering stages and an<br />

adsorption dryer, ensure the purity of the<br />

compressed air. These systems are equipped<br />

with three compressors and two compressed<br />

air receivers, filter systems, and pressure<br />

reducer stations. They are constructed in<br />

such a way to ensure the utmost reliability as<br />

well as to maintain and repair without having<br />

to interrupt normal operations.<br />

Medical Air Plants acc. to <strong>ISO</strong> 7396-1<br />

Main components of a Dräger Medical<br />

Air Plant are 3 or 4 compressors, an<br />

energy or control panel, 2 air receivers,<br />

2 EcoPharm-Towers 5-stage<br />

conditioning systems with filters and<br />

adsorption dryers and a pressure<br />

reducer station. The installation fully<br />

complies with the standard DIN EN <strong>ISO</strong><br />

7396-1 and the produced air is air for<br />

medical use according to the European<br />

Pharmacopoeia.<br />

The compressors build the three air<br />

sources of the plant. Taking various<br />

aspects into consideration e.g.<br />

economics, reliability, service, oil<br />

lubricated compressors are selected.<br />

The air receiver’s capacity size is<br />

related to the compressors output to<br />

comply with the hourly stop and start ratio<br />

laid down by the manufacturer and<br />

produce steady flow. The EcoPharm-<br />

Tower conditioning systems reduce the<br />

air humidity to an atmospheric dew point<br />

of -46°C to prevent condensate in the<br />

piping system and allow the filter system<br />

to achieve the air quality according to the<br />

European Pharmacopoeia.<br />

The pressure reducer stations related to<br />

flow provide constant line distribution<br />

pressure for breathing systems and<br />

surgical tools.

COMPRESSED AIR SYSTEMS | GAS MANAGEMENT SYSTEMS | 25<br />

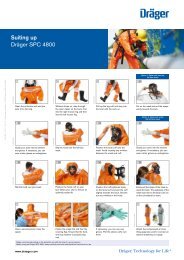

CONFIGURATION OF A MEDICAL COMPRESSED AIR PLANT<br />

D-9368-2009<br />

Configuration of a medical compressed air plant<br />

CONFIGURATION OF A MEDICAL COMPRESSED AIR PLANT<br />

ACC. TO DIN EN <strong>ISO</strong> 7396-1<br />

Medical compressed air plant with DWSC piston compressors<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

I<br />

J<br />

K<br />

L<br />

M<br />

Compressor<br />

Air receiver<br />

Condensate drain<br />

Dryer<br />

5-stage Filter/Purification Unit<br />

Pressure reducing station 5 bar<br />

Pressure reducing station 8 bar<br />

Distribution block<br />

Emergency/Maintenance/Sampling point*<br />

Oil-water-separator<br />

Energy panel/Control panel<br />

Medical AIR Guard (Option)<br />

Cyclone separator (Option for screw compressors)<br />

*For main ring systems in the central supply system a sample port with a<br />

shut-off valve shall be additionally provided immediately downstream of the<br />

conditioning system.

26 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

PISTON COMPRESSORS DWSC SERIES<br />

PISTON COMPRESSORS DWSC SERIES 50 HZ<br />

Piston compressor in compact, super sound-absorbing tower design to<br />

generate a max. operating pressure of 15 bar. Complete with all required<br />

cooling-, control-, and monitoring facilities, version for 50 Hz voltage supply.<br />

Per system 1 master control and 1 to 3 slave compressors are required.<br />

DWSC 3 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSC 3 (Focus) 50 Hz Slave<br />

Piston Compressor DWSC 3 (Focus) 50 Hz Master<br />

G31441<br />

G31341<br />

DWSC 4 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSC 4 (Focus) 50 Hz Slave<br />

Piston Compressor DWSC 4 (Focus) 50 Hz Master<br />

G31442<br />

G31342<br />

Piston compressor DWSC<br />

DWSC 6 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSC 6 (Focus) 50 Hz Slave<br />

Piston Compressor DWSC 6 (Focus) 50 Hz Master<br />

G31443<br />

G31343<br />

DWSC 8 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSC 8 (Focus) 50 Hz Slave<br />

Piston Compressor DWSC 8 (Focus) 50 Hz Master<br />

G31444<br />

G31344<br />

DWSC 10 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSC 10 (Focus) 50 Hz Slave<br />

Piston Compressor DWSC 10 (Focus) 50 Hz Master<br />

G31445<br />

G31345<br />

DWSC 15 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSC 15 (Focus) 50 Hz Slave<br />

Piston Compressor DWSC 15 (Focus) 50 Hz Master<br />

G31446<br />

G31346<br />

DWSC 8 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSC 20 (Focus) 50 Hz Slave<br />

Piston Compressor DWSC 20 (Focus) 50 Hz Master<br />

G31447<br />

G31347

COMPRESSED AIR SYSTEMS | GAS MANAGEMENT SYSTEMS | 27<br />

PISTON COMPRESSORS DWSC SERIES<br />

PISTON COMPRESSORS DWSC SERIES 60 HZ<br />

Piston compressor in compact, super sound-absorbing tower design to<br />

generate a max. operating pressure of 15 bar. Complete with all required<br />

cooling-, control-, and monitoring facilities, version for 60 Hz voltage supply.<br />

Per system 1 master control and 1 to 3 slave compressors are required.<br />

DWSC 3 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSC 3 (Focus) 60 Hz Slave<br />

Piston Compressor DWSC 3 (Focus) 60 Hz Master<br />

G31448<br />

G31348<br />

DWSC 4 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSC 4 (Focus) 60 Hz Slave<br />

Piston Compressor DWSC 4 (Focus) 60 Hz Master<br />

G31449<br />

G31349<br />

Piston compressor DWSC<br />

DWSC 6 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSC 6 (Focus) 60 Hz Slave<br />

Piston Compressor DWSC 6 (Focus) 60 Hz Master<br />

G31450<br />

G31350<br />

DWSC 8 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSC 8 (Focus) 60 Hz Slave<br />

Piston Compressor DWSC 8 (Focus) 60 Hz Master<br />

G31451<br />

G31351<br />

DWSC 10 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSC 10 (Focus) 60 Hz Slave<br />

Piston Compressor DWSC 10 (Focus) 60 Hz Master<br />

G31452<br />

G31352<br />

DWSC 15 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSC 15 (Focus) 60 Hz Slave<br />

Piston Compressor DWSC 15 (Focus) 60 Hz Master<br />

G31453<br />

G31353<br />

DWSC 8 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSC 20 (Focus) 60 Hz Slave<br />

Piston Compressor DWSC 20 (Focus) 60 Hz Master<br />

G31454<br />

G31354

28 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

PISTON COMPRESSORS DWSC SERIES<br />

TECHNICAL DATA PISTON COMPRESSOR DWSC TYPES 50 HZ<br />

Color<br />

Operating voltage<br />

Control voltage<br />

Dimensions (L×W×H)<br />

RAL 5012 (blue)<br />

400 V/50 Hz AC<br />

230 V/50 Hz AC<br />

1120 × 715 × 1570 mm³<br />

Description Order no. Free air delivery 1) Revs. No. of cylinders Motor Sound level 2) Weight<br />

l/min m³/h 1/min kW dB(A) kg<br />

DWSC 3 (Focus) 50 Hz Slave G31441 283 17.0 650 2 2.2 62 337<br />

DWSC 3 (Focus) 50 Hz Master G31341 283 17.0 650 2 2.2 62 337<br />

DWSC 4 (Focus) 50 Hz Slave G31442 394 23.6 920 2 3.0 65 343<br />

DWSC 4 (Focus) 50 Hz Master G31342 394 23.6 920 2 3.0 65 343<br />

DWSC 6 (Focus) 50 Hz Slave G31443 541 32.5 625 3 4.0 66 368<br />

DWSC 6 (Focus) 50 Hz Master G31343 541 32.5 625 3 4.0 66 368<br />

DWSC 8 (Focus) 50 Hz Slave G31444 693 41.6 830 3 5.5 70 390<br />

DWSC 8 (Focus) 50 Hz Master G31344 693 41.6 830 3 5.5 70 390<br />

DWSC 10 (Focus) 50 Hz Slave G31445 928 55.7 1130 3 7.5 71 397<br />

DWSC 10 (Focus) 50 Hz Master G31345 928 55.7 1130 3 7.5 71 397<br />

DWSC 15 (Focus) 50 Hz Slave G31446 1319 79.1 1130 4 11.0 72 463<br />

DWSC 15 (Focus) 50 Hz Master G31346 1319 79.1 1130 4 11.0 72 463<br />

DWSC 20 (Focus) 50 Hz Slave G31447 1615 96.9 1400 4 15.0 74 473<br />

DWSC 20 (Focus) 50 Hz Master G31347 1615 96.9 1400 4 15.0 74 473<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13

COMPRESSED AIR SYSTEMS | GAS MANAGEMENT SYSTEMS | 29<br />

PISTON COMPRESSORS DWSC SERIES<br />

TECHNICAL DATA PISTON COMPRESSOR DWSC TYPES 60 HZ<br />

Color<br />

Operating voltage<br />

Control voltage<br />

Dimensions (L×W×H)<br />

RAL 5012 (blue)<br />

380 V/60 Hz AC<br />

220 V/60 Hz AC<br />

1120 × 715 × 1570 mm³<br />

Description Order no. Free air delivery 1) Revs. No. of cylinders Motor Sound level 2) Weight<br />

l/min m³/h 1/min kW dB(A) kg<br />

DWSC 3 (Focus) 60 Hz Slave G31448 283 17.0 650 2 2.2 62 337<br />

DWSC 3 (Focus) 60 Hz Master G31348 283 17.0 650 2 2.2 62 337<br />

DWSC 4 (Focus) 60 Hz Slave G31449 394 23.6 920 2 3.0 65 343<br />

DWSC 4 (Focus) 60 Hz Master G31349 394 23.6 920 2 3.0 65 343<br />

DWSC 6 (Focus) 60 Hz Slave G31450 541 32.5 625 3 4.0 66 368<br />

DWSC 6 (Focus) 60 Hz Master G31350 541 32.5 625 3 4.0 66 368<br />

DWSC 8 (Focus) 60 Hz Slave G31451 693 41.6 830 3 5.5 70 390<br />

DWSC 8 (Focus) 60 Hz Master G31351 693 41.6 830 3 5.5 70 390<br />

DWSC 10 (Focus) 60 Hz Slave G31452 928 55.7 1130 3 7.5 71 397<br />

DWSC 10 (Focus) 60 Hz Master G31352 928 55.7 1130 3 7.5 71 397<br />

DWSC 15 (Focus) 60 Hz Slave G31453 1319 79.1 1130 4 11.0 72 463<br />

DWSC 15 (Focus) 60 Hz Master G31353 1319 79.1 1130 4 11.0 72 463<br />

DWSC 20 (Focus) 60 Hz Slave G31454 1615 96.9 1400 4 15.0 74 473<br />

DWSC 20 (Focus) 60 Hz Master G31354 1615 96.9 1400 4 15.0 74 473<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13

i<br />

30 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

SCREW COMPRESSORS DWLC/DWLS SERIES<br />

SCREW COMPRESSORS DWLC/DWLS SERIES 50 HZ<br />

C 9<br />

Screw compressors in compact, super sound-absorbing tower design to<br />

generate a max. operating pressure of 13 bar. Complete with all required<br />

cooling-, control-, and monitoring facilities, version for 50 Hz voltage supply.<br />

Per system 1 master control and 1 to 3 slave compressors are required.<br />

DWLC 7 <strong>–</strong> 50 Hz<br />

Screw Compressor DWLC 7 (Focus) 50 Hz Slave<br />

Screw Compressor DWLC 7 (Focus) 50 Hz Master<br />

G31455<br />

G31355<br />

DWLC 9 <strong>–</strong> 50 Hz<br />

Screw Compressor DWLC 9 (Focus) 50 Hz Slave<br />

Screw Compressor DWLC 9 (Focus) 50 Hz Master<br />

G31456<br />

G31356<br />

Screw compressor DWLC/DWLS<br />

DWLC 15 <strong>–</strong> 50 Hz<br />

Screw Compressor DWLC 15 (Focus) 50 Hz Slave<br />

Screw Compressor DWLC 15 (Focus) 50 Hz Master<br />

G31457<br />

G31357<br />

DWLC 20 <strong>–</strong> 50 Hz<br />

Screw Compressor DWLC 20 (Focus) 50 Hz Slave<br />

Screw Compressor DWLC 20 (Focus) 50 Hz Master<br />

G31458<br />

G31358<br />

DWLC 25 <strong>–</strong> 50 Hz<br />

Screw Compressor DWLC 25 (Focus) 50 Hz Slave<br />

Screw Compressor DWLC 25 (Focus) 50 Hz Master<br />

G31459<br />

G31359<br />

DWLC 30 <strong>–</strong> 50 Hz<br />

Screw Compressor DWLC 30 (Focus) 50 Hz Slave<br />

Screw Compressor DWLC 30 (Focus) 50 Hz Master<br />

G31460<br />

G31360<br />

DWLC 40 <strong>–</strong> 50 Hz<br />

Screw Compressor DWLS 40 (Focus) 50 Hz Slave<br />

Screw Compressor DWLS 40 (Focus) 50 Hz Master<br />

G31467<br />

G31367<br />

DWLC 50 <strong>–</strong> 50 Hz<br />

Screw Compressor DWLS 50 (Focus) 50 Hz Slave<br />

Screw Compressor DWLS 50 (Focus) 50 Hz Master<br />

G31468<br />

G31368

COMPRESSED AIR SYSTEMS | GAS MANAGEMENT SYSTEMS | 31<br />

SCREW COMPRESSORS DWLC/DWLS SERIES<br />

TECHNICAL DATA SCREW COMPRESSOR DWLC/DWLS TYPES 50 HZ<br />

Color<br />

Operating voltage<br />

Control voltage<br />

RAL 5012 (blue)<br />

400 V/50 Hz AC<br />

230 V/50 Hz AC<br />

Description Order no. Free air delivery 1) Motor/fan AIR outlet Fan thrust Cooling air Sound level 2) Weight<br />

demand<br />

m³/h (l/min) kW Pa Nm³/h dB(A) kg<br />

DWLC 7 (Focus) 50 Hz Slave G31455 39.12 (652) 5.5 G½ 50 1500 64 243.5<br />

DWLC 7 (Focus) 50 Hz Master G31355 39.12 (652) 5.5 G½ 50 1500 64 243.5<br />

DWLC 9 (Focus) 50 Hz Slave G31456 54 (900) 7.5 G½ 50 2000 68 219<br />

DWLC 9 (Focus) 50 Hz Master G31356 54 (900) 7.5 G½ 50 2000 68 219<br />

Dimensions (L×W×H)<br />

480 × 920 × 960 mm<br />

DWLC 15 (Focus) 50 Hz Slave G31457 79.8 (1330) 11.0 G1 50 1700 67 410<br />

DWLC 15 (Focus) 50 Hz Master G31357 79.8 (1330) 11.0 G1 50 1700 67 410<br />

DWLC 20 (Focus) 50 Hz Slave G31458 113.4 (1890) 15.0 G1 50 2500 65 438<br />

DWLC 20 (Focus) 50 Hz Master G31358 113.4 (1890) 15.0 G1 50 2500 65 438<br />

DWLC 25 (Focus) 50 Hz Slave G31459 139.2 (2320) 18.5 G1 50 3100 68 499<br />

DWLC 25 (Focus) 50 Hz Master G31359 139.2 (2320) 18.5 G1 50 3100 68 499<br />

DWLC 30 (Focus) 50 Hz Slave G31460 162.6 (2710) 22.0 G1 50 3450 69 461<br />

DWLC 30 (Focus) 50 Hz Master G31360 162.6 (2710) 22.0 G1 50 3450 69 461<br />

Dimensions (L×W×H)<br />

772 × 1056 × 1735 mm<br />

DWLS 40 (Focus) 50 Hz Slave G31467 229.2 (3820) 30.0 G1¼ 60 5500 76 784<br />

DWLS 40 (Focus) 50 Hz Master G31367 229.2 (3820) 30.0 G1¼ 60 5500 76 784<br />

DWLS 50 (Focus) 50 Hz Slave G31468 297 (4950) 37.0 G1¼ 60 6500 78 804<br />

DWLS 50 (Focus) 50 Hz Master G31368 297 (4950) 37.0 G1¼ 60 6500 78 804<br />

Dimensions (L×W×H)<br />

1615 × 990 × 1450 mm<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13

i<br />

32 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

SCREW COMPRESSORS DWLC/DWLS SERIES<br />

SCREW COMPRESSORS DWLC/DWLS SERIES 60 HZ<br />

C 9<br />

Screw compressors in compact, super sound-absorbing tower design to<br />

generate a max. operating pressure of 13 bar. Complete with all required<br />

cooling-, control-, and monitoring facilities, version for 60 Hz voltage supply.<br />

Per system 1 master control and 1 to 3 slave compressors are required.<br />

DWLC 7 <strong>–</strong> 60 Hz<br />

Screw Compressor DWLC 7 (Focus) 60 Hz Slave<br />

Screw Compressor DWLC 7 (Focus) 60 Hz Master<br />

G31461<br />

G31361<br />

DWLC 9 <strong>–</strong> 60 Hz<br />

Screw Compressor DWLC 9 (Focus) 60 Hz Slave<br />

Screw Compressor DWLC 9 (Focus) 60 Hz Master<br />

G31462<br />

G31362<br />

Screw compressor DWLC/DWLS<br />

DWLC 15 <strong>–</strong> 60 Hz<br />

Screw Compressor DWLC 15 (Focus) 60 Hz Slave<br />

Screw Compressor DWLC 15 (Focus) 60 Hz Master<br />

G31463<br />

G31363<br />

DWLC 20 <strong>–</strong> 60 Hz<br />

Screw Compressor DWLC 20 (Focus) 50 Hz Slave<br />

Screw Compressor DWLC 20 (Focus) 50 Hz Master<br />

G31464<br />

G31364<br />

DWLC 25 <strong>–</strong> 60 Hz<br />

Screw Compressor DWLC 25 (Focus) 60 Hz Slave<br />

Screw Compressor DWLC 25 (Focus) 60 Hz Master<br />

G31465<br />

G31365<br />

DWLC 30 <strong>–</strong> 60 Hz<br />

Screw Compressor DWLC 30 (Focus) 60 Hz Slave<br />

Screw Compressor DWLC 30 (Focus) 60 Hz Master<br />

G31466<br />

G31366<br />

DWLC 40 <strong>–</strong> 60 Hz<br />

Screw Compressor DWLS 40 (Focus) 60 Hz Slave<br />

Screw Compressor DWLS 40 (Focus) 60 Hz Master<br />

G31469<br />

G31369<br />

DWLC 50 <strong>–</strong> 60 Hz<br />

Screw Compressor DWLS 50 (Focus) 60 Hz Slave<br />

Screw Compressor DWLS 50 (Focus) 60 Hz Master<br />

G31470<br />

G31370

COMPRESSED AIR SYSTEMS | GAS MANAGEMENT SYSTEMS | 33<br />

SCREW COMPRESSORS DWLC/DWLS SERIES<br />

TECHNICAL DATA SCREW COMPRESSOR DWLC/DWLS TYPES 60 HZ<br />

Color<br />

Operating voltage<br />

Control voltage<br />

RAL 5012 (blue)<br />

380 V/60 Hz AC<br />

220 V/60 Hz AC<br />

Description Order no. Free air delivery 1) Motor/fan AIR outlet Fan thrust Cooling air Sound level 2) Weight<br />

demand<br />

m³/h (l/min) kW Pa Nm³/h dB(A) kg<br />

DWLC 7 (Focus) 60 Hz Slave G31461 39.12 (652) 5.5 G½ 50 1500 64 243.5<br />

DWLC 7 (Focus) 60 Hz Master G31361 39.12 (652) 5.5 G½ 50 1500 64 243.5<br />

DWLC 9 (Focus) 60 Hz Slave G31462 54.0 (900) 7.5 G½ 50 2000 68 219<br />

DWLC 9 (Focus) 60 Hz Master G31362 54.0 (900) 7.5 G½ 50 2000 68 219<br />

Dimensions (L×W×H)<br />

480 × 920 × 960 mm<br />

DWLC 15 (Focus) 60 Hz Slave G31463 79.8 (1330) 11.0 G1 50 1700 67 410<br />

DWLC 15 (Focus) 60 Hz Master G31363 79.8 (1330) 11.0 G1 50 1700 67 410<br />

DWLC 20 (Focus) 60 Hz Slave G31464 113.4 (1890) 15.0 G1 50 2500 65 438<br />

DWLC 20 (Focus) 60 Hz Master G31364 113.4 (1890) 15.0 G1 50 2500 65 438<br />

DWLC 25 (Focus) 60 Hz Slave G31465 139.2 (2320) 18.5 G1 50 3100 68 499<br />

DWLC 25 (Focus) 60 Hz Master G31365 139.2 (2320) 18.5 G1 50 3100 68 499<br />

DWLC 30 (Focus) 60 Hz Slave G31466 162.6 (2710) 22.0 G1 50 3450 69 461<br />

DWLC 30 (Focus) 60 Hz Master G31366 162.6 (2710) 22.0 G1 50 3450 69 461<br />

Dimensions (L×W×H)<br />

772 × 1056 × 1735 mm<br />

DWLS 40 (Focus) 60 Hz Slave G31469 229.2 (3820) 30.0 G1¼ 60 5500 76 784<br />

DWLS 40 (Focus) 60 Hz Master G31369 229.2 (3820) 30.0 G1¼ 60 5500 76 784<br />

DWLS 50 (Focus) 60 Hz Slave G31470 297 (4950) 37.0 G1¼ 60 6500 78 804<br />

DWLS 50 (Focus) 60 Hz Master G31370 297 (4950) 37.0 G1¼ 60 6500 78 804<br />

Dimensions (L×W×H)<br />

1615 × 990 × 1450 mm<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13

34 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

PISTON COMPRESSORS DWSRM SERIES<br />

PISTON COMPRESSORS DWSRM SERIES 50 HZ<br />

Oil-lubricated piston compressors, two-stage, air-cooled, to generate a max.<br />

operating pressure of 15 bar, version for 50 Hz voltage supply.<br />

DWSRM 320 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRM 320, 50 Hz<br />

G30476<br />

DWSRM 450 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRM 450, 50 Hz<br />

G30477<br />

DWSRM 610 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRM 610, 50 Hz<br />

G30479<br />

Piston compressor DWSRM<br />

DWSRM 800 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRM 800, 50 Hz<br />

G30480<br />

DWSRM 1100 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRM 1100, 50 Hz<br />

G30481<br />

DWSRM 1640 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRM 1640, 50 Hz<br />

G30483<br />

DWSRM 2030 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRM 2030, 50 Hz<br />

G30484<br />

PISTON COMPRESSORS DWSRM SERIES 60 HZ<br />

Oil-lubricated piston compressors, two-stage, air-cooled, to generate a max.<br />

operating pressure of 15 bar, version for 60 Hz voltage supply.<br />

DWSRM 320 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRM 320, 60 Hz<br />

G30870<br />

DWSRM 450 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRM 450, 60 Hz<br />

G30871<br />

DWSRM 610 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRM 610, 60 Hz<br />

G30872<br />

DWSRM 800 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRM 800, 60 Hz<br />

G30873<br />

DWSRM 1100 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRM 1100, 60 Hz<br />

G30874<br />

DWSRM 1640 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRM 1640, 60 Hz<br />

G30875<br />

DWSRM 2030 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRM 2030, 60 Hz<br />

G30876

COMPRESSED AIR SYSTEMS | GAS MANAGEMENT SYSTEMS | 35<br />

PISTON COMPRESSORS DWSRM SERIES<br />

TECHNICAL DATA PISTON COMPRESSORS DWSRM TYPES 50 HZ<br />

Color<br />

Operating voltage<br />

Control voltage<br />

RAL 5012 (blue)<br />

400 V/50 Hz AC<br />

230 V/50 Hz AC<br />

Description Order no. Free air delivery 1) Revs. No. of cylinders Motor Sound level 2) Weight<br />

l/min m³/h 1/min kW dB(A) kg<br />

Compressor DWSRM 320 G30476 283 17.0 650 2 2.2 73 145<br />

Compressor DWSRM 450 G30477 394 23.6 920 2 3.0 74 155<br />

Dimensions (L×W×H)<br />

1300 × 700 × 890 mm<br />

Compressor DWSRM 610 G30479 541 32.5 625 3 4.0 75 195<br />

Compressor DWSRM 800 G30480 693 41.6 830 3 5.5 77 215<br />

Compressor DWSRM 1100 G30481 928 55.7 1130 3 7.5 79 220<br />

Dimensions (L×W×H)<br />

1300 × 740 × 890 mm<br />

Compressor DWSRM 1640 G30483 1319 79.1 1130 4 11.0 82 260<br />

Compressor DWSRM 2030 G30484 1615 96.9 1400 4 15.0 87 260<br />

Dimensions (L×W×H)<br />

1330 × 920 × 890 mm<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13<br />

TECHNICAL DATA PISTON COMPRESSORS DWSRM TYPES 60 HZ<br />

Color<br />

Operating voltage<br />

Control voltage<br />

RAL 5012 (blue)<br />

380 V/60 Hz AC<br />

220 V/60 Hz AC<br />

Description Order no. Free air delivery 1) Revs. No. of cylinders Motor Sound level 2) Weight<br />

l/min m³/h 1/min kW dB(A) kg<br />

Compressor DWSRM 320 G30870 283 17.0 650 2 2.2 73 145<br />

Compressor DWSRM 450 G30871 394 23.6 920 2 3.0 74 155<br />

Dimensions (L×W×H)<br />

1300 × 700 × 890 mm<br />

Compressor DWSRM 610 G30872 541 32.5 625 3 4.0 75 195<br />

Compressor DWSRM 800 G30873 693 41.6 830 3 5.5 77 215<br />

Compressor DWSRM 1100 G30874 928 55.7 1130 3 7.5 79 220<br />

Dimensions (L×W×H)<br />

1300 × 740 × 890 mm<br />

Compressor DWSRM 1640 G30875 1319 79.1 1130 4 11.0 82 260<br />

Compressor DWSRM 2030 G30876 1615 96.9 1400 4 15.0 87 260<br />

Dimensions (L×W×H)<br />

1330 × 920 × 890 mm<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13

36 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

PISTON COMPRESSORS DWSBM SERIES<br />

PISTON COMPRESSORS DWSBM SERIES 50 HZ<br />

Oil-lubricated piston compressors, two-stage, air-cooled, to generate a max.<br />

operating pressure of 15 bar, aggregate mounted on horizontal tank version<br />

for 50 Hz voltage supply.<br />

DWSBM 320/350 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSBM 320/350, 50 Hz<br />

G30493<br />

D<br />

DWSBM 450/500 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSBM 450/500, 50 Hz<br />

G30494<br />

DWSBM 610/500 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSBM 610/500, 50 Hz<br />

G30615<br />

Piston compressor DWSBM<br />

DWSBM 800/500 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSBM 800/500, 50 Hz<br />

G30616<br />

DWSBM 1100/500 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSBM 1100/500, 50 Hz<br />

G30704<br />

DWSBM 1640/750 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSBM 1640/750, 50 Hz<br />

G30705

COMPRESSED AIR SYSTEMS | GAS MANAGEMENT SYSTEMS | 37<br />

PISTON COMPRESSORS DWSBM SERIES<br />

TECHNICAL DATA PISTON COMPRESSORS DWSBM TYPES 50 HZ<br />

Operating voltage<br />

Control voltage<br />

400 V/50 Hz AC<br />

230 V/50 Hz AC<br />

other voltages/frequencies on request<br />

Description Order no. Free air delivery 1) Revs. No. of cylinders Motor Sound level 2) Weight<br />

l/min m³/h 1/min kW dB(A) kg<br />

Compressor DWSBM 320/350 G30493 283 17.0 920 350 2.2 75 320<br />

Dimensions (L×W×H)<br />

1930 × 600 × 1470 mm<br />

Compressor DWSBM 450/500 G30494 394 23.6 920 500 3.0 84.5 390<br />

Dimensions (L×W×H)<br />

1920 × 600 × 1520 mm<br />

Compressor DWSBM 610/500 G30615 541 32.5 625 500 4.0 82 415<br />

Compressor DWSBM 800/500 G30616 693 41.6 830 500 5.5 83 430<br />

Dimensions (L×W×H)<br />

1920 × 600 × 1530 mm<br />

Compressor DWSBM 1100/500 G30704 928 55.7 1130 500 7.5 83 435<br />

Dimensions (L×W×H)<br />

1930 × 600 × 1100 mm<br />

Compressor DWSBM 1640/750 G30705 1319 7 9.1 1130 750 11 86 555<br />

Dimensions (L×W×H)<br />

200 × 660 × 110 mm<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13

38 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

PISTON COMPRESSORS DWSRD SERIES<br />

PISTON COMPRESSORS DWSRD SERIES 50 HZ<br />

Compressor aggregates for an end pressure of 10 bar and a delivery quantity<br />

of 75 -730 l/min, version for 50 Hz voltage supply.<br />

DWSRD 125 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRD 125, 10 bar, 50 Hz<br />

G30708<br />

Piston compressor DWSRD 125<br />

DWSRD 250 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRD 250, 10 bar, 50 Hz<br />

G30709<br />

DWSRD 350 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRD 350, 10 bar, 50 Hz<br />

G30710<br />

DWSRD 500 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRD 500, 10 bar, 50 Hz<br />

G30711<br />

DWSRD 700 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRD 700, 10 bar, 50 Hz<br />

G30712<br />

Piston compressor DWSRD 250<br />

DWSRD 100 <strong>–</strong> 50 Hz<br />

Piston Compressor DWSRD 1000, 10 bar, 50 Hz<br />

G30713<br />

PISTON COMPRESSORS DWSRD SERIES 60 HZ<br />

Compressor aggregates for an end pressure of 10 bar and a delivery quantity<br />

of 75 -730 l/min, version for 60 Hz voltage supply.<br />

DWSRD 125 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRD 125, 10 bar, 60 Hz<br />

G30880<br />

DWSRD 250 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRD 250, 10 bar, 60 Hz<br />

G30881<br />

DWSRD 350 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRD 350, 10 bar, 60 Hz<br />

G30882<br />

DWSRD 500 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRD 500, 10 bar, 60 Hz<br />

G30883<br />

DWSRD 700 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRD 700, 10 bar, 60 Hz<br />

G30884<br />

DWSRD 100 <strong>–</strong> 60 Hz<br />

Piston Compressor DWSRD 1000, 10 bar, 60 Hz<br />

G30885

COMPRESSED AIR SYSTEMS | GAS MANAGEMENT SYSTEMS | 39<br />

PISTON COMPRESSORS DWSRD SERIES<br />

TECHNICAL DATA PISTON COMPRESSOR DWSRD 10 BAR TYPES 50 HZ<br />

Color<br />

Operating voltage<br />

Control voltage<br />

RAL 5012 (blue)<br />

400 V/50 Hz AC<br />

230 V/50 Hz AC<br />

Description Order no. Free air delivery 1) Motor/fan Cooling air demand Sound level 2) Weight<br />

m³/h (l/min) kW Nm³/h dB(A) kg<br />

Compressor DWSRD 125 G30708 4.5 (75) 0.75 320 80 32<br />

Dimensions (L×W×H)<br />

470 × 275 × 340 mm<br />

Compressor DWSRD 250 G30709 9.4 (156) 1.5 640 80 38<br />

Dimensions (L×W×H)<br />

485 × 345 × 335 mm<br />

Compressor DWSRD 350 G30710 15.6 (260) 2.2 1800 78 69.5<br />

Compressor DWSRD 500 G30711 22.2 (370) 3.2 2270 78 70.5<br />

Dimensions (L×W×H)<br />

765 × 408 × 582 mm<br />

Compressor DWSRD 700 G30712 30.9 (515) 4.0 2270 78 96.5<br />

Compressor DWSRD 1000 G30713 43.8 (730) 6.3 3025 78 104.5<br />

Dimensions (L×W×H)<br />

690 × 520 × 584 mm<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13<br />

TECHNICAL DATA PISTON COMPRESSOR DWSRD 10 BAR TYPES 60 HZ<br />

Color<br />

Operating voltage<br />

Control voltage<br />

RAL 5012 (blue)<br />

380 V/60 Hz AC<br />

220 V/60 Hz AC<br />

Description Order no. Free air delivery 1) Motor/fan Cooling air demand Sound level 2) Weight<br />

m³/h (l/min) kW Nm³/h dB(A) kg<br />

Compressor DWSRD 125 G30880 4.5 (75) 0.75 320 80 32<br />

Dimensions (L×W×H)<br />

470 × 275 × 340 mm<br />

Compressor DWSRD 250 G30881 9.4 (156) 1.5 640 80 38<br />

Dimensions (L×W×H)<br />

485 × 345 × 335 mm<br />

Compressor DWSRD 350 G30882 15.6 (260) 2.2 1800 78 69.5<br />

Compressor DWSRD 500 G30883 22.2 (370) 3.2 2270 78 70.5<br />

Dimensions (L×W×H)<br />

765 × 408 × 582 mm<br />

Compressor DWSRD 700 G30884 30.9 (515) 4.0 2270 78 96.5<br />

Compressor DWSRD 1000 G30885 43.8 (730) 6.3 3025 78 104.5<br />

Dimensions (L×W×H)<br />

690 × 520 × 584 mm<br />

1)<br />

Acc. to VDMA 4362 related to STP<br />

2)<br />

Acc. to DIN 45635-part 13

40 | GAS MANAGEMENT SYSTEMS | COMPRESSED AIR SYSTEMS<br />

CONTROL PANELS<br />

CONTROL PANELS<br />

ENERGY PANEL FOR COMPRESSORS DWSC/DWLC/DWLS SERIES<br />

Energy panel for the energy supply and the provision of signalling contacts of<br />

compressed air systems with 2, 3 or 4 compressors with integrated control unit<br />

"Focus" (DWSC/DWLC/DWLS).<br />