Gas Management Systems System Components Catalogue – ISO Standard

With over 50 years of experience in the planning and manufacturing of medical gas management systems, Dräger is one of the market and technology leaders in Germany as well as in the international market. Our systems, installed and maintained by Dräger installation specialists and DrägerService technicians, offer premium reliability and safety, above-average durability, and meet the highest quality standards. Medical gases (oxygen, compressed air, nitrous oxide, and carbon dioxide) and vacuum must be safely and reliably available at all times. We deliver tailor-made system solutions, so that your hospital always has the correct gas available in the correct quantities and quality. From planning consultation to assembly and subsequent after-sales service, we provide complete services from one source regardless of whether it is a new development, an enlargement or a renovation. Not all articles are available worldwide.

With over 50 years of experience in the planning and manufacturing of medical

gas management systems, Dräger is one of the market and technology leaders

in Germany as well as in the international market.

Our systems, installed and maintained by Dräger installation specialists and

DrägerService technicians, offer premium reliability and safety, above-average

durability, and meet the highest quality standards.

Medical gases (oxygen, compressed air, nitrous oxide, and carbon dioxide) and

vacuum must be safely and reliably available at all times. We deliver tailor-made

system solutions, so that your hospital always has the correct gas available in the

correct quantities and quality. From planning consultation to assembly and

subsequent after-sales service, we provide complete services from one source

regardless of whether it is a new development, an enlargement or a renovation.

Not all articles are available worldwide.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

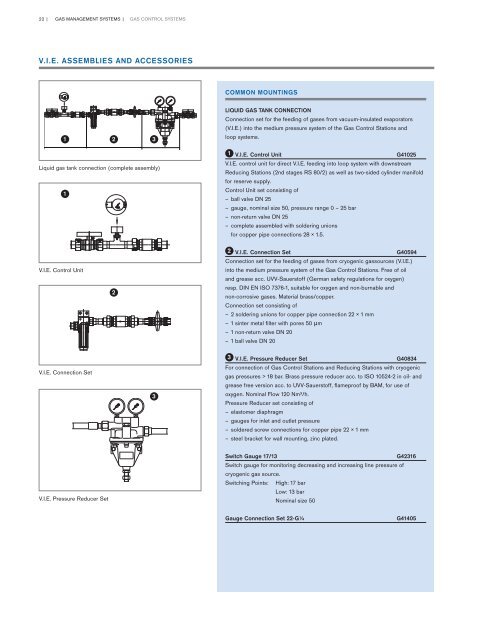

22 | GAS MANAGEMENT SYSTEMS | GAS CONTROL SYSTEMS<br />

V.I.E. ASSEMBLIES AND ACCESSORIES<br />

COMMON MOUNTINGS<br />

LIQUID GAS TANK CONNECTION<br />

Connection set for the feeding of gases from vacuum-insulated evaporators<br />

(V.I.E.) into the medium pressure system of the <strong>Gas</strong> Control Stations and<br />

1<br />

2<br />

3<br />

loop systems.<br />

Liquid gas tank connection (complete assembly)<br />

1<br />

1 V.I.E. Control Unit<br />

G41025<br />

V.I.E. control unit for direct V.I.E. feeding into loop system with downstream<br />

Reducing Stations (2nd stages RS 80/2) as well as two-sided cylinder manifold<br />

for reserve supply.<br />

Control Unit set consisting of<br />

<strong>–</strong> ball valve DN 25<br />

<strong>–</strong> gauge, nominal size 50, pressure range 0 <strong>–</strong> 25 bar<br />

<strong>–</strong> non-return valve DN 25<br />

<strong>–</strong> complete assembled with soldering unions<br />

for copper pipe connections 28 × 1.5.<br />

V.I.E. Control Unit<br />

2<br />

2 V.I.E. Connection Set<br />

G40594<br />

Connection set for the feeding of gases from cryogenic gassources (V.I.E.)<br />

into the medium pressure system of the <strong>Gas</strong> Control Stations. Free of oil<br />

and grease acc. UVV-Sauerstoff (German safety regulations for oxygen)<br />

resp. DIN EN <strong>ISO</strong> 7376-1, suitable for oxygen and non-burnable and<br />

non-corrosive gases. Material brass/copper.<br />

Connection set consisting of<br />

<strong>–</strong> 2 soldering unions for copper pipe connection 22 × 1 mm<br />

<strong>–</strong> 1 sinter metal filter with pores 50 μm<br />

<strong>–</strong> 1 non-return valve DN 20<br />

<strong>–</strong> 1 ball valve DN 20<br />

V.I.E. Connection Set<br />

3<br />

3 V.I.E. Pressure Reducer Set<br />

G40834<br />

For connection of <strong>Gas</strong> Control Stations and Reducing Stations with cryogenic<br />

gas pressures > 18 bar. Brass pressure reducer acc. to <strong>ISO</strong> 10524-2 in oil- and<br />

grease free version acc. to UVV-Sauerstoff, flameproof by BAM, for use of<br />

oxygen. Nominal Flow 120 Nm³/h.<br />

Pressure Reducer set consisting of<br />

<strong>–</strong> elastomer diaphragm<br />

<strong>–</strong> gauges for inlet and outlet pressure<br />

<strong>–</strong> soldered screw connections for copper pipe 22 × 1 mm<br />

<strong>–</strong> steel bracket for wall mounting, zinc plated.<br />

V.I.E. Pressure Reducer Set<br />

Switch Gauge 17/13<br />

G42316<br />

Switch gauge for monitoring decreasing and increasing line pressure of<br />

cryogenic gas source.<br />

Switching Points: High: 17 bar<br />

Low: 13 bar<br />

Nominal size 50<br />

Gauge Connection Set 22-G¼<br />

G41405