1JxQXyD

1JxQXyD

1JxQXyD

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sports Venues – Projects<br />

ARCHITECTURE<br />

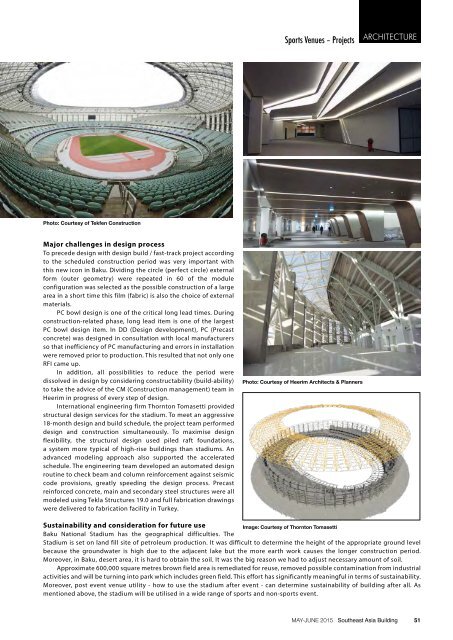

Photo: Courtesy of Tekfen Construction<br />

Major challenges in design process<br />

To precede design with design build / fast-track project according<br />

to the scheduled construction period was very important with<br />

this new icon in Baku. Dividing the circle (perfect circle) external<br />

form (outer geometry) were repeated in 60 of the module<br />

configuration was selected as the possible construction of a large<br />

area in a short time this film (fabric) is also the choice of external<br />

materials.<br />

PC bowl design is one of the critical long lead times. During<br />

construction-related phase, long lead item is one of the largest<br />

PC bowl design item. In DD (Design development), PC (Precast<br />

concrete) was designed in consultation with local manufacturers<br />

so that inefficiency of PC manufacturing and errors in installation<br />

were removed prior to production. This resulted that not only one<br />

RFI came up.<br />

In addition, all possibilities to reduce the period were<br />

dissolved in design by considering constructability (build-ability)<br />

to take the advice of the CM (Construction management) team in<br />

Heerim in progress of every step of design.<br />

International engineering firm Thornton Tomasetti provided<br />

structural design services for the stadium. To meet an aggressive<br />

18-month design and build schedule, the project team performed<br />

design and construction simultaneously. To maximise design<br />

flexibility, the structural design used piled raft foundations,<br />

a system more typical of high-rise buildings than stadiums. An<br />

advanced modeling approach also supported the accelerated<br />

schedule. The engineering team developed an automated design<br />

routine to check beam and column reinforcement against seismic<br />

code provisions, greatly speeding the design process. Precast<br />

reinforced concrete, main and secondary steel structures were all<br />

modeled using Tekla Structures 19.0 and full fabrication drawings<br />

were delivered to fabrication facility in Turkey.<br />

Photo: Courtesy of Heerim Architects & Planners<br />

Sustainability and consideration for future use<br />

Image: Courtesy of Thornton Tomasetti<br />

Baku National Stadium has the geographical difficulties. The<br />

Stadium is set on land fill site of petroleum production. It was difficult to determine the height of the appropriate ground level<br />

because the groundwater is high due to the adjacent lake but the more earth work causes the longer construction period.<br />

Moreover, in Baku, desert area, it is hard to obtain the soil. It was the big reason we had to adjust necessary amount of soil.<br />

Approximate 600,000 square metres brown field area is remediated for reuse, removed possible contamination from industrial<br />

activities and will be turning into park which includes green field. This effort has significantly meaningful in terms of sustainability.<br />

Moreover, post event venue utility - how to use the stadium after event - can determine sustainability of building after all. As<br />

mentioned above, the stadium will be utilised in a wide range of sports and non-sports event.<br />

MAY-JUNE 2015 Southeast Asia Building 51