Wind Turbine

Wind Turbine

Wind Turbine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

chemical<br />

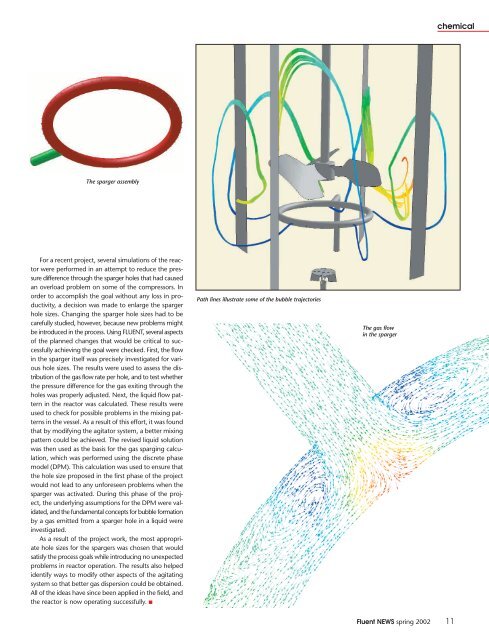

The sparger assembly<br />

For a recent project, several simulations of the reactor<br />

were performed in an attempt to reduce the pressure<br />

difference through the sparger holes that had caused<br />

an overload problem on some of the compressors. In<br />

order to accomplish the goal without any loss in productivity,<br />

a decision was made to enlarge the sparger<br />

hole sizes. Changing the sparger hole sizes had to be<br />

carefully studied, however, because new problems might<br />

be introduced in the process. Using FLUENT, several aspects<br />

of the planned changes that would be critical to successfully<br />

achieving the goal were checked. First, the flow<br />

in the sparger itself was precisely investigated for various<br />

hole sizes. The results were used to assess the distribution<br />

of the gas flow rate per hole, and to test whether<br />

the pressure difference for the gas exiting through the<br />

holes was properly adjusted. Next, the liquid flow pattern<br />

in the reactor was calculated. These results were<br />

used to check for possible problems in the mixing patterns<br />

in the vessel. As a result of this effort, it was found<br />

that by modifying the agitator system, a better mixing<br />

pattern could be achieved. The revised liquid solution<br />

was then used as the basis for the gas sparging calculation,<br />

which was performed using the discrete phase<br />

model (DPM). This calculation was used to ensure that<br />

the hole size proposed in the first phase of the project<br />

would not lead to any unforeseen problems when the<br />

sparger was activated. During this phase of the project,<br />

the underlying assumptions for the DPM were validated,<br />

and the fundamental concepts for bubble formation<br />

by a gas emitted from a sparger hole in a liquid were<br />

investigated.<br />

As a result of the project work, the most appropriate<br />

hole sizes for the spargers was chosen that would<br />

satisfy the process goals while introducing no unexpected<br />

problems in reactor operation. The results also helped<br />

identify ways to modify other aspects of the agitating<br />

system so that better gas dispersion could be obtained.<br />

All of the ideas have since been applied in the field, and<br />

the reactor is now operating successfully. ■<br />

Path lines illustrate some of the bubble trajectories<br />

The gas flow<br />

in the sparger<br />

Fluent NEWS spring 2002 11