Wind Turbine

Wind Turbine

Wind Turbine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

chemical<br />

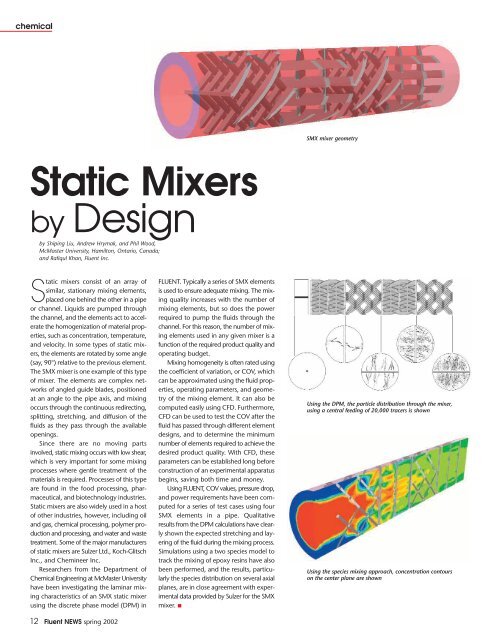

SMX mixer geometry<br />

Static Mixers<br />

by Design<br />

by Shiping Liu, Andrew Hrymak, and Phil Wood,<br />

McMaster University, Hamilton, Ontario, Canada;<br />

and Rafiqul Khan, Fluent Inc.<br />

Static mixers consist of an array of<br />

similar, stationary mixing elements,<br />

placed one behind the other in a pipe<br />

or channel. Liquids are pumped through<br />

the channel, and the elements act to accelerate<br />

the homogenization of material properties,<br />

such as concentration, temperature,<br />

and velocity. In some types of static mixers,<br />

the elements are rotated by some angle<br />

(say, 90°) relative to the previous element.<br />

The SMX mixer is one example of this type<br />

of mixer. The elements are complex networks<br />

of angled guide blades, positioned<br />

at an angle to the pipe axis, and mixing<br />

occurs through the continuous redirecting,<br />

splitting, stretching, and diffusion of the<br />

fluids as they pass through the available<br />

openings.<br />

Since there are no moving parts<br />

involved, static mixing occurs with low shear,<br />

which is very important for some mixing<br />

processes where gentle treatment of the<br />

materials is required. Processes of this type<br />

are found in the food processing, pharmaceutical,<br />

and biotechnology industries.<br />

Static mixers are also widely used in a host<br />

of other industries, however, including oil<br />

and gas, chemical processing, polymer production<br />

and processing, and water and waste<br />

treatment. Some of the major manufacturers<br />

of static mixers are Sulzer Ltd., Koch-Glitsch<br />

Inc., and Chemineer Inc.<br />

Researchers from the Department of<br />

Chemical Engineering at McMaster University<br />

have been investigating the laminar mixing<br />

characteristics of an SMX static mixer<br />

using the discrete phase model (DPM) in<br />

FLUENT. Typically a series of SMX elements<br />

is used to ensure adequate mixing. The mixing<br />

quality increases with the number of<br />

mixing elements, but so does the power<br />

required to pump the fluids through the<br />

channel. For this reason, the number of mixing<br />

elements used in any given mixer is a<br />

function of the required product quality and<br />

operating budget.<br />

Mixing homogeneity is often rated using<br />

the coefficient of variation, or COV, which<br />

can be approximated using the fluid properties,<br />

operating parameters, and geometry<br />

of the mixing element. It can also be<br />

computed easily using CFD. Furthermore,<br />

CFD can be used to test the COV after the<br />

fluid has passed through different element<br />

designs, and to determine the minimum<br />

number of elements required to achieve the<br />

desired product quality. With CFD, these<br />

parameters can be established long before<br />

construction of an experimental apparatus<br />

begins, saving both time and money.<br />

Using FLUENT, COV values, pressure drop,<br />

and power requirements have been computed<br />

for a series of test cases using four<br />

SMX elements in a pipe. Qualitative<br />

results from the DPM calculations have clearly<br />

shown the expected stretching and layering<br />

of the fluid during the mixing process.<br />

Simulations using a two species model to<br />

track the mixing of epoxy resins have also<br />

been performed, and the results, particularly<br />

the species distribution on several axial<br />

planes, are in close agreement with experimental<br />

data provided by Sulzer for the SMX<br />

mixer. ■<br />

Using the DPM, the particle distribution through the mixer,<br />

using a central feeding of 20,000 tracers is shown<br />

Using the species mixing approach, concentration contours<br />

on the center plane are shown<br />

12 Fluent NEWS spring 2002