featured in this issue - NZIFST - The New Zealand Institute of Food ...

featured in this issue - NZIFST - The New Zealand Institute of Food ...

featured in this issue - NZIFST - The New Zealand Institute of Food ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

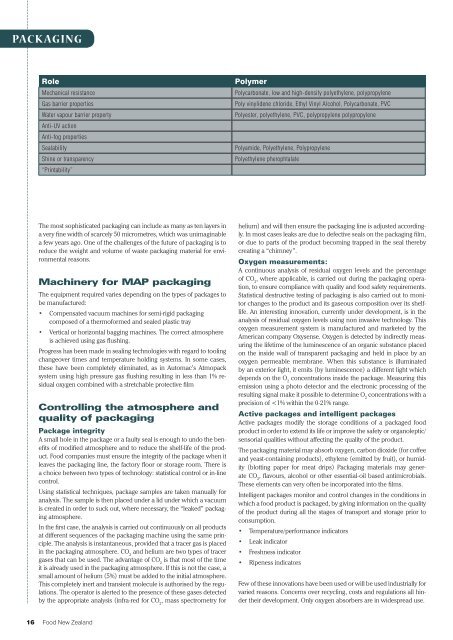

PACKAGING<br />

Role<br />

Mechanical resistance<br />

Gas barrier properties<br />

Water vapour barrier property<br />

Anti-UV action<br />

Anti-fog properties<br />

Sealability<br />

Sh<strong>in</strong>e or transparency<br />

“Pr<strong>in</strong>tability”<br />

Polymer<br />

Polycarbonate, low and high-density polyethylene, polypropylene<br />

Poly v<strong>in</strong>ylidene chloride, Ethyl V<strong>in</strong>yl Alcohol, Polycarbonate, PVC<br />

Polyester, polyethylene, PVC, polypropylene polypropylene<br />

Polyamide, Polyethylene, Polypropylene<br />

Polyethylene pherophtalate<br />

<strong>The</strong> most sophisticated packag<strong>in</strong>g can <strong>in</strong>clude as many as ten layers <strong>in</strong><br />

a very f<strong>in</strong>e width <strong>of</strong> scarcely 50 micrometres, which was unimag<strong>in</strong>able<br />

a few years ago. One <strong>of</strong> the challenges <strong>of</strong> the future <strong>of</strong> packag<strong>in</strong>g is to<br />

reduce the weight and volume <strong>of</strong> waste packag<strong>in</strong>g material for environmental<br />

reasons.<br />

Mach<strong>in</strong>ery for MAP packag<strong>in</strong>g<br />

<strong>The</strong> equipment required varies depend<strong>in</strong>g on the types <strong>of</strong> packages to<br />

be manufactured:<br />

• Compensated vacuum mach<strong>in</strong>es for semi-rigid packag<strong>in</strong>g<br />

composed <strong>of</strong> a therm<strong>of</strong>ormed and sealed plastic tray<br />

• Vertical or horizontal bagg<strong>in</strong>g mach<strong>in</strong>es. <strong>The</strong> correct atmosphere<br />

is achieved us<strong>in</strong>g gas flush<strong>in</strong>g.<br />

Progress has been made <strong>in</strong> seal<strong>in</strong>g technologies with regard to tool<strong>in</strong>g<br />

changeover times and temperature hold<strong>in</strong>g systems. In some cases,<br />

these have been completely elim<strong>in</strong>ated, as <strong>in</strong> Automac’s Atmopack<br />

system us<strong>in</strong>g high pressure gas flush<strong>in</strong>g result<strong>in</strong>g <strong>in</strong> less than 1% residual<br />

oxygen comb<strong>in</strong>ed with a stretchable protective film<br />

Controll<strong>in</strong>g the atmosphere and<br />

quality <strong>of</strong> packag<strong>in</strong>g<br />

Package <strong>in</strong>tegrity<br />

A small hole <strong>in</strong> the package or a faulty seal is enough to undo the benefits<br />

<strong>of</strong> modified atmosphere and to reduce the shelf-life <strong>of</strong> the product.<br />

<strong>Food</strong> companies must ensure the <strong>in</strong>tegrity <strong>of</strong> the package when it<br />

leaves the packag<strong>in</strong>g l<strong>in</strong>e, the factory floor or storage room. <strong>The</strong>re is<br />

a choice between two types <strong>of</strong> technology: statistical control or <strong>in</strong>-l<strong>in</strong>e<br />

control.<br />

Us<strong>in</strong>g statistical techniques, package samples are taken manually for<br />

analysis. <strong>The</strong> sample is then placed under a lid under which a vacuum<br />

is created <strong>in</strong> order to suck out, where necessary, the “leaked” packag<strong>in</strong>g<br />

atmosphere.<br />

In the first case, the analysis is carried out cont<strong>in</strong>uously on all products<br />

at different sequences <strong>of</strong> the packag<strong>in</strong>g mach<strong>in</strong>e us<strong>in</strong>g the same pr<strong>in</strong>ciple.<br />

<strong>The</strong> analysis is <strong>in</strong>stantaneous, provided that a tracer gas is placed<br />

<strong>in</strong> the packag<strong>in</strong>g atmosphere. CO 2<br />

and helium are two types <strong>of</strong> tracer<br />

gases that can be used. <strong>The</strong> advantage <strong>of</strong> CO 2<br />

is that most <strong>of</strong> the time<br />

it is already used <strong>in</strong> the packag<strong>in</strong>g atmosphere. If <strong>this</strong> is not the case, a<br />

small amount <strong>of</strong> helium (5%) must be added to the <strong>in</strong>itial atmosphere.<br />

This completely <strong>in</strong>ert and transient molecule is authorised by the regulations.<br />

<strong>The</strong> operator is alerted to the presence <strong>of</strong> these gases detected<br />

by the appropriate analysis (<strong>in</strong>fra-red for CO 2<br />

, mass spectrometry for<br />

helium) and will then ensure the packag<strong>in</strong>g l<strong>in</strong>e is adjusted accord<strong>in</strong>gly.<br />

In most cases leaks are due to defective seals on the packag<strong>in</strong>g film,<br />

or due to parts <strong>of</strong> the product becom<strong>in</strong>g trapped <strong>in</strong> the seal thereby<br />

creat<strong>in</strong>g a “chimney”.<br />

Oxygen measurements:<br />

A cont<strong>in</strong>uous analysis <strong>of</strong> residual oxygen levels and the percentage<br />

<strong>of</strong> CO 2<br />

, where applicable, is carried out dur<strong>in</strong>g the packag<strong>in</strong>g operation,<br />

to ensure compliance with quality and food safety requirements.<br />

Statistical destructive test<strong>in</strong>g <strong>of</strong> packag<strong>in</strong>g is also carried out to monitor<br />

changes to the product and its gaseous composition over its shelflife.<br />

An <strong>in</strong>terest<strong>in</strong>g <strong>in</strong>novation, currently under development, is <strong>in</strong> the<br />

analysis <strong>of</strong> residual oxygen levels us<strong>in</strong>g non <strong>in</strong>vasive technology. This<br />

oxygen measurement system is manufactured and marketed by the<br />

American company Oxysense. Oxygen is detected by <strong>in</strong>directly measur<strong>in</strong>g<br />

the lifetime <strong>of</strong> the lum<strong>in</strong>escence <strong>of</strong> an organic substance placed<br />

on the <strong>in</strong>side wall <strong>of</strong> transparent packag<strong>in</strong>g and held <strong>in</strong> place by an<br />

oxygen permeable membrane. When <strong>this</strong> substance is illum<strong>in</strong>ated<br />

by an exterior light, it emits (by lum<strong>in</strong>escence) a different light which<br />

depends on the O 2<br />

concentrations <strong>in</strong>side the package. Measur<strong>in</strong>g <strong>this</strong><br />

emission us<strong>in</strong>g a photo detector and the electronic process<strong>in</strong>g <strong>of</strong> the<br />

result<strong>in</strong>g signal make it possible to determ<strong>in</strong>e O 2<br />

concentrations with a<br />

precision <strong>of</strong>