Download PDF - Hot-Mix Magazine

Download PDF - Hot-Mix Magazine

Download PDF - Hot-Mix Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

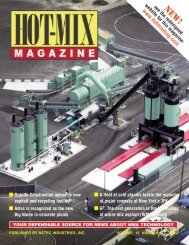

The manifold on this Heatec HC heater connects to four independent hot oil circuits, each with its own side pump. Independent circuits provide more operating<br />

options than single circuits.<br />

When water is detected it should<br />

be purged from the system.<br />

This can take from two hours<br />

to two days or longer, resulting<br />

in downtime for the heater. The<br />

purge time depends on the<br />

amount of heat transfer oil in<br />

the system, the amount of water<br />

in the oil, and how the piping<br />

system is designed.<br />

How Does Water Get In?<br />

The expansion tank<br />

accommodates expansion and<br />

contraction of heat transfer<br />

oil during normal operation<br />

of the heating system. The<br />

tank is partially filled with heat<br />

transfer oil and is vented to the<br />

atmosphere (the unfilled space<br />

in the tank consists of air). As<br />

the heat transfer oil cools, it<br />

contracts and draws in fresh<br />

air. The cooling process causes<br />

moisture in the air to condense<br />

into water, which collects in the<br />

heat transfer oil and eventually<br />

moves into the heating circuit.<br />

Purging the Water<br />

Heatec HC or HCS heaters are<br />

designed to facilitate purging<br />

If you increase the temperatures in<br />

increments in excess of 10 degrees, the<br />

expansion tank may boil over. It is also<br />

important to make sure all the steam has<br />

exited the overflow/vent pipe to prevent<br />

the expansion tank from boiling over.<br />

water from the hot oil system.<br />

The most effective way to remove<br />

the water from their system<br />

is convert it to steam in the<br />

expansion tank and allow it to<br />

escape into the atmosphere. But<br />

this process must be confined<br />

to the expansion tank while<br />

avoiding the creation of steam in<br />

the circulating system. It requires<br />

careful manipulation of oil<br />

temperature and pressure.<br />

The process of purging water<br />

from the system includes several<br />

steps that require the resetting<br />

of valves on the heater to reroute<br />

the return fluid directly through<br />

the expansion tank. Since air in<br />

the expansion tank is constantly<br />

at atmospheric pressure, a<br />

temperature of 212 degrees<br />

Fahrenheit is all that is needed<br />

to change water into steam so it<br />

can escape through the overflow/<br />

vent pipe.<br />

It is important to create and<br />

maintain a back pressure by<br />

adjusting the valve at the inlet of<br />

the expansion tank to restrict the<br />

flow of the fluid diverted into the<br />

tank. When doing so, be aware<br />

that increasing system pressure<br />

beyond its usual operating<br />

pressure can rupture worn parts.<br />

Always start cold and heat the<br />

oil slowly in increments of 10<br />

degrees to allow the water to boil<br />

out progressively. Failure to do so<br />

may create a violent reaction in<br />

the expansion tank as the waterladen<br />

heat transfer oil enters<br />

the tank and its pressure drops<br />

suddenly due to atmospheric<br />

pressure.<br />

Preventive Maintenance<br />

Routinely purging water from<br />

the hot oil heating system<br />

should be part of the preventive<br />

maintenance plan. By keeping the<br />

system in good working order,<br />

the heater will last longer and<br />

cost less to operate. <br />

FOR MORE INFORMATION<br />

about purging water from hot oil systems at HMA plants,<br />

call Heatec Service Manager Ron Henry<br />

800-235-5200<br />

Fax: 423-821-7673 • E-mail: rhenry@heatec.com<br />

HOT-MIX MAGAZINE 32 VOLUME 16 NUMBER 1