Module 3 - Benjamin-Mills

Module 3 - Benjamin-Mills

Module 3 - Benjamin-Mills

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SS2.2<br />

WHAT CHANGES OCCUR DURING STEELMAKING?<br />

Changes in temperature<br />

4 Using the information in Table 1, plot a graph to illustrate how the<br />

temperature of the metal changes during the BOS process.<br />

5 Draw a dotted line across your graph to show the target tapping<br />

temperature. (This is the ideal temperature for steel leaving the converter at<br />

the end of the oxygen blow.)<br />

b The freezing point of pure iron is 1539°C yet the metal arriving from<br />

the blast furnace is molten at a temperature of 1333°C. Why has it<br />

not solidified?<br />

c Write a short explanation of the changes in temperature shown by<br />

your graph.<br />

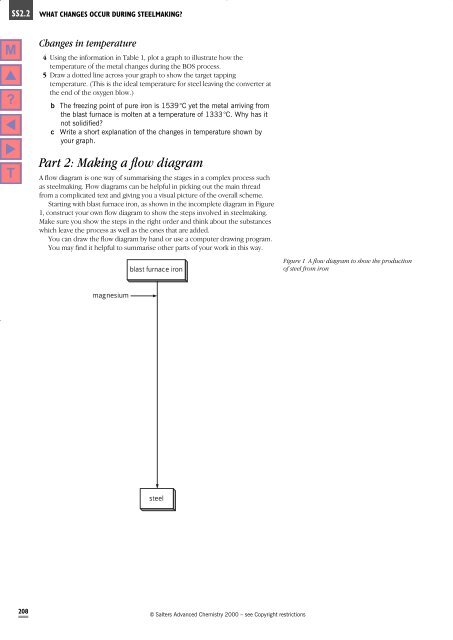

Part 2: Making a flow diagram<br />

A flow diagram is one way of summarising the stages in a complex process such<br />

as steelmaking. Flow diagrams can be helpful in picking out the main thread<br />

from a complicated text and giving you a visual picture of the overall scheme.<br />

Starting with blast furnace iron, as shown in the incomplete diagram in Figure<br />

1, construct your own flow diagram to show the steps involved in steelmaking.<br />

Make sure you show the steps in the right order and think about the substances<br />

which leave the process as well as the ones that are added.<br />

You can draw the flow diagram by hand or use a computer drawing program.<br />

You may find it helpful to summarise other parts of your work in this way.<br />

blast furnace iron<br />

Figure 1 A flow diagram to show the production<br />

of steel from iron<br />

magnesium<br />

steel<br />

208<br />

„ Salters Advanced Chemistry 2000 – see Copyright restrictions

![ISI Web of Knowledge [v.4.10] - All Databases Results - Benjamin-Mills](https://img.yumpu.com/39253071/1/184x260/isi-web-of-knowledge-v410-all-databases-results-benjamin-mills.jpg?quality=85)