Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Melt quality and melt cleaning<br />

All factors which come under the general<br />

term of “melt quality” have a direct<br />

effect on the quality of the casting to be<br />

produced. Inversely, according to DIN EN<br />

1706, the cast samples play a valuable<br />

role in checking the quality of the melt.<br />

Most problems in casting are caused by<br />

two natural properties of liquid melts, i.e.<br />

their marked tendency to form oxides<br />

and their tendency towards hydrogen<br />

absorption. Furthermore, other insoluble<br />

impurities, such as Al-carbides or<br />

refractory particles as well as impurities<br />

with iron, play an important role.<br />

As mentioned in other sections, the<br />

larger oxide fi lm can lead to a material<br />

separation in the microstructure and,<br />

consequently, to a reduction in the load-<br />

bearing cross-section of the casting.<br />

The solubility of hydrogen in aluminium<br />

decreases discontinuously during the<br />

transition from liquid to solid so that as<br />

solidifi cation takes place, precipitating<br />

gaseous hydrogen reacting with existing<br />

oxides can cause voids which can<br />

in turn take various forms ranging from<br />

large pipe-like blisters to fi nely-distributed<br />

micro-porosity.<br />

24<br />

<strong>Aluminium</strong> <strong>Casting</strong> <strong>Alloys</strong><br />

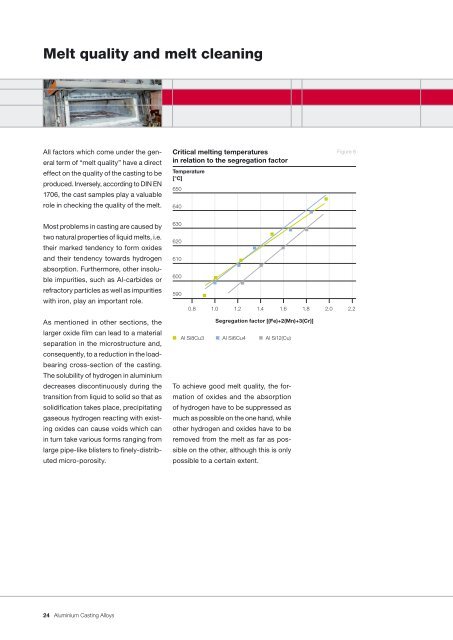

Critical melting temperatures<br />

in relation to the segregation factor<br />

Temperature<br />

[°C]<br />

650<br />

640<br />

630<br />

620<br />

610<br />

600<br />

590<br />

0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2<br />

Segregation factor [(Fe)+2(Mn)+3(Cr)]<br />

Al Si8Cu3 Al Si6Cu4 Al Si12(Cu)<br />

To achieve good melt quality, the for-<br />

mation of oxides and the absorption<br />

of hydrogen have to be suppressed as<br />

much as possible on the one hand, while<br />

other hydrogen and oxides have to be<br />

removed from the melt as far as possible<br />

on the other, although this is only<br />

possible to a certain extent.<br />

Figure 6