Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Heat treatment of aluminium castings<br />

Heat treatment gives users of castings<br />

the possibility of specifi cally improv-<br />

ing the mechanical properties or even<br />

chemical resistance. Depending on the<br />

casting type, the following common and<br />

applied methods for aluminium castings<br />

can be used:<br />

Stress relieving<br />

Stabilising<br />

Homogenising<br />

Soft annealing<br />

Age-hardening.<br />

The most important form of heat treatment<br />

for aluminium castings is artifi cial<br />

ageing. Further information is provided<br />

below.<br />

40<br />

<strong>Aluminium</strong> <strong>Casting</strong> <strong>Alloys</strong><br />

Ageing time [h]<br />

Metallurgy – fundamental principles<br />

For age-hardening to take place, there<br />

must be a decreasing solubility of a par-<br />

ticular alloy constituent in the α-solid so-<br />

lution with falling temperature. As a rule,<br />

age-hardening comprises three steps:<br />

In solution annealing, suffi cient amounts<br />

of the important constituents for age-<br />

hardening are dissolved in the α-solid<br />

solution.<br />

With rapid quenching, these constituents<br />

remain in solution. Afterwards, the parts<br />

are relatively soft.<br />

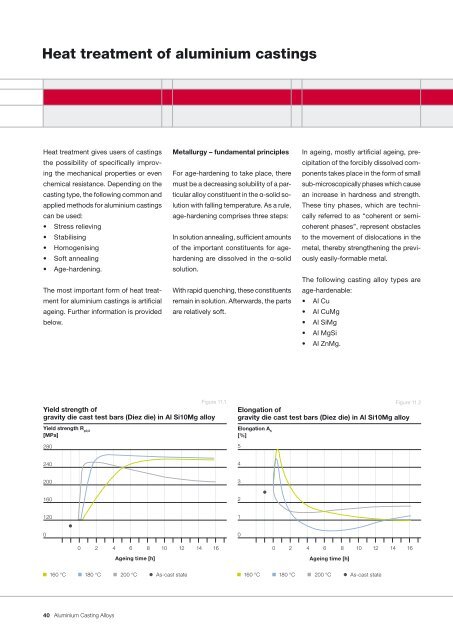

Figure 11.1<br />

Yield strength of<br />

gravity die cast test bars (Diez die) in Al Si10Mg alloy<br />

Yield strength R p0,2<br />

[MPa]<br />

280<br />

240<br />

200<br />

160<br />

120<br />

0<br />

0 2 4 6 8 10 12 14 16<br />

160 °C 180 °C 200 °C<br />

As-cast state<br />

In ageing, mostly artifi cial ageing, precipitation<br />

of the forcibly dissolved components<br />

takes place in the form of small<br />

sub-microscopically phases which cause<br />

an increase in hardness and strength.<br />

These tiny phases, which are technically<br />

referred to as “coherent or semicoherent<br />

phases”, represent obstacles<br />

to the movement of dislocations in the<br />

metal, thereby strengthening the previously<br />

easily-formable metal.<br />

The following casting alloy types are<br />

age-hardenable:<br />

Al Cu<br />

Al CuMg<br />

Al SiMg<br />

Al MgSi<br />

Al ZnMg.<br />

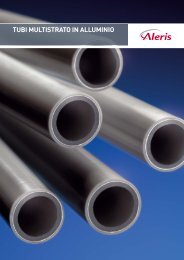

Figure 11.2<br />

Elongation of<br />

gravity die cast test bars (Diez die) in Al Si10Mg alloy<br />

Elongation A5 [%]<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0 2 4 6 8 10 12 14 16<br />

Ageing time [h]<br />

160 °C 180 °C 200 °C<br />

As-cast state