Energy saving in compressed air systems - Norgren Pneumatics ...

Energy saving in compressed air systems - Norgren Pneumatics ...

Energy saving in compressed air systems - Norgren Pneumatics ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

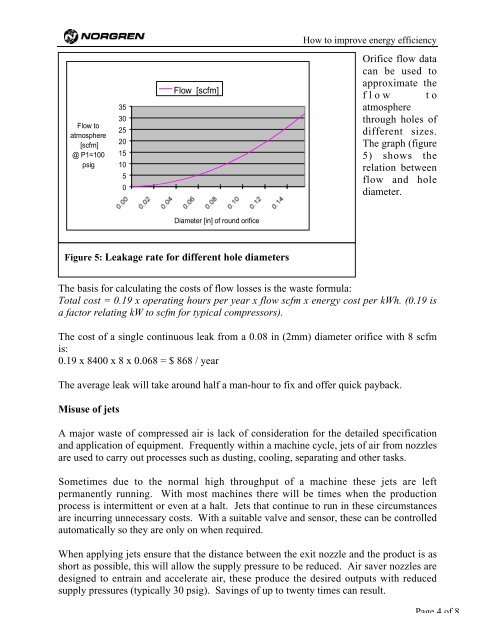

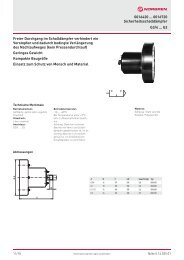

Flow to<br />

atmosphere<br />

[scfm]<br />

@ P1=100<br />

psig<br />

How to improve energy efficiency<br />

Orifice flow data<br />

can be used to<br />

approximate the<br />

flow to<br />

atmosphere<br />

through holes of<br />

different sizes.<br />

The graph (figure<br />

5) shows the<br />

relation between<br />

flow and hole<br />

diameter.<br />

The basis for calculat<strong>in</strong>g the costs of flow losses is the waste formula:<br />

Total cost = 0.19 x operat<strong>in</strong>g hours per year x flow scfm x energy cost per kWh. (0.19 is<br />

a factor relat<strong>in</strong>g kW to scfm for typical compressors).<br />

The cost of a s<strong>in</strong>gle cont<strong>in</strong>uous leak from a 0.08 <strong>in</strong> (2mm) diameter orifice with 8 scfm<br />

is:<br />

0.19 x 8400 x 8 x 0.068 = $ 868 / year<br />

The average leak will take around half a man-hour to fix and offer quick payback.<br />

Misuse of jets<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Flow [scfm]<br />

Diameter [<strong>in</strong>] of round orifice<br />

Figure 5: Leakage rate for different hole diameters<br />

A major waste of <strong>compressed</strong> <strong>air</strong> is lack of consideration for the detailed specification<br />

and application of equipment. Frequently with<strong>in</strong> a mach<strong>in</strong>e cycle, jets of <strong>air</strong> from nozzles<br />

are used to carry out processes such as dust<strong>in</strong>g, cool<strong>in</strong>g, separat<strong>in</strong>g and other tasks.<br />

Sometimes due to the normal high throughput of a mach<strong>in</strong>e these jets are left<br />

permanently runn<strong>in</strong>g. With most mach<strong>in</strong>es there will be times when the production<br />

process is <strong>in</strong>termittent or even at a halt. Jets that cont<strong>in</strong>ue to run <strong>in</strong> these circumstances<br />

are <strong>in</strong>curr<strong>in</strong>g unnecessary costs. With a suitable valve and sensor, these can be controlled<br />

automatically so they are only on when required.<br />

When apply<strong>in</strong>g jets ensure that the distance between the exit nozzle and the product is as<br />

short as possible, this will allow the supply pressure to be reduced. Air saver nozzles are<br />

designed to entra<strong>in</strong> and accelerate <strong>air</strong>, these produce the desired outputs with reduced<br />

supply pressures (typically 30 psig). Sav<strong>in</strong>gs of up to twenty times can result.<br />

Page 4 of 8