PDF (342 kb ) - Agence canadienne d'inspection des aliments

PDF (342 kb ) - Agence canadienne d'inspection des aliments

PDF (342 kb ) - Agence canadienne d'inspection des aliments

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

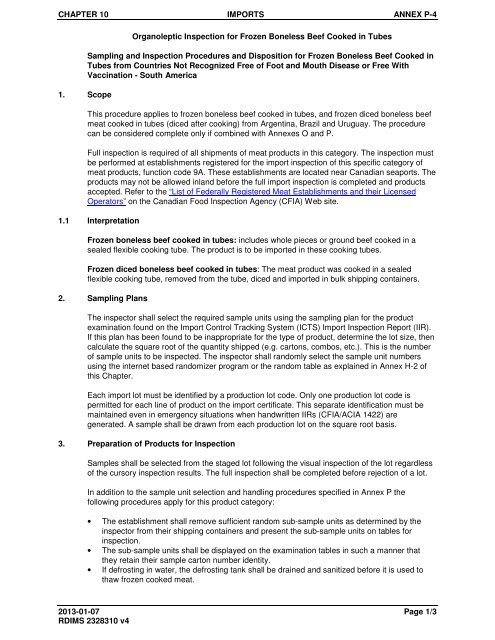

CHAPTER 10 IMPORTS ANNEX P-41. ScopeOrganoleptic Inspection for Frozen Boneless Beef Cooked in TubesSampling and Inspection Procedures and Disposition for Frozen Boneless Beef Cooked inTubes from Countries Not Recognized Free of Foot and Mouth Disease or Free WithVaccination - South AmericaThis procedure applies to frozen boneless beef cooked in tubes, and frozen diced boneless beefmeat cooked in tubes (diced after cooking) from Argentina, Brazil and Uruguay. The procedurecan be considered complete only if combined with Annexes O and P.Full inspection is required of all shipments of meat products in this category. The inspection mustbe performed at establishments registered for the import inspection of this specific category ofmeat products, function code 9A. These establishments are located near Canadian seaports. Theproducts may not be allowed inland before the full import inspection is completed and productsaccepted. Refer to the “List of Federally Registered Meat Establishments and their LicensedOperators” on the Canadian Food Inspection Agency (CFIA) Web site.1.1 InterpretationFrozen boneless beef cooked in tubes: inclu<strong>des</strong> whole pieces or ground beef cooked in asealed flexible cooking tube. The product is to be imported in these cooking tubes.Frozen diced boneless beef cooked in tubes: The meat product was cooked in a sealedflexible cooking tube, removed from the tube, diced and imported in bulk shipping containers.2. Sampling PlansThe inspector shall select the required sample units using the sampling plan for the productexamination found on the Import Control Tracking System (ICTS) Import Inspection Report (IIR).If this plan has been found to be inappropriate for the type of product, determine the lot size, thencalculate the square root of the quantity shipped (e.g. cartons, combos, etc.). This is the numberof sample units to be inspected. The inspector shall randomly select the sample unit numbersusing the internet based randomizer program or the random table as explained in Annex H-2 ofthis Chapter.Each import lot must be identified by a production lot code. Only one production lot code ispermitted for each line of product on the import certificate. This separate identification must bemaintained even in emergency situations when handwritten IIRs (CFIA/ACIA 1422) aregenerated. A sample shall be drawn from each production lot on the square root basis.3. Preparation of Products for InspectionSamples shall be selected from the staged lot following the visual inspection of the lot regardlessof the cursory inspection results. The full inspection shall be completed before rejection of a lot.In addition to the sample unit selection and handling procedures specified in Annex P thefollowing procedures apply for this product category:• The establishment shall remove sufficient random sub-sample units as determined by theinspector from their shipping containers and present the sub-sample units on tables forinspection.• The sub-sample units shall be displayed on the examination tables in such a manner thatthey retain their sample carton number identity.• If defrosting in water, the defrosting tank shall be drained and sanitized before it is used tothaw frozen cooked meat.2013-01-07 Page 1/3RDIMS 2328310 v4