2009 Issue 1 - Raytheon

2009 Issue 1 - Raytheon

2009 Issue 1 - Raytheon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RF SYSTEMS<br />

Continued from page 31<br />

The production of AESAs for many military<br />

applications began in earnest in the early<br />

1990s. Packaging the microwave electronic<br />

circuitry in most cases required hermetic<br />

environmental protection, and along with<br />

the corresponding interconnects, thermal<br />

control, etc., dictated the weight and volume<br />

of the AESAs. Today’s AESAs have<br />

evolved to lighter, denser packages —<br />

some with hermetic packages and some<br />

exploiting alternative environmental protection<br />

technologies. This evolution, along<br />

with technology improvements in MMICs,<br />

interconnects, thermal control, etc., have<br />

realized a 50 percent savings in both<br />

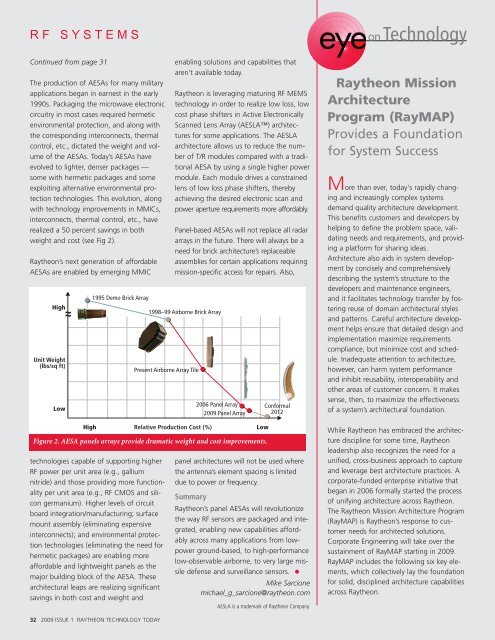

weight and cost (see Fig 2).<br />

<strong>Raytheon</strong>’s next generation of affordable<br />

AESAs are enabled by emerging MMIC<br />

High<br />

Unit Weight<br />

(lbs/sq ft)<br />

Low<br />

1995 Demo Brick Array<br />

technologies capable of supporting higher<br />

RF power per unit area (e.g., gallium<br />

nitride) and those providing more functionality<br />

per unit area (e.g., RF CMOS and silicon<br />

germanium). Higher levels of circuit<br />

board integration/manufacturing; surface<br />

mount assembly (eliminating expensive<br />

interconnects); and environmental protection<br />

technologies (eliminating the need for<br />

hermetic packages) are enabling more<br />

affordable and lightweight panels as the<br />

major building block of the AESA. These<br />

architectural leaps are realizing significant<br />

savings in both cost and weight and<br />

32 <strong>2009</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

enabling solutions and capabilities that<br />

aren’t available today.<br />

<strong>Raytheon</strong> is leveraging maturing RF MEMS<br />

technology in order to realize low loss, low<br />

cost phase shifters in Active Electronically<br />

Scanned Lens Array (AESLA) architectures<br />

for some applications. The AESLA<br />

architecture allows us to reduce the number<br />

of T/R modules compared with a traditional<br />

AESA by using a single higher power<br />

module. Each module drives a constrained<br />

lens of low loss phase shifters, thereby<br />

achieving the desired electronic scan and<br />

power aperture requirements more affordably.<br />

Panel-based AESAs will not replace all radar<br />

arrays in the future. There will always be a<br />

need for brick architecture’s replaceable<br />

assemblies for certain applications requiring<br />

mission-specific access for repairs. Also,<br />

1998–99 Airborne Brick Array<br />

Present Airborne Array Tile<br />

2006 Panel Array<br />

<strong>2009</strong> Panel Array<br />

High Relative Production Cost (%)<br />

Low<br />

Figure 2. AESA panels arrays provide dramatic weight and cost improvements.<br />

Conformal<br />

2012<br />

panel architectures will not be used where<br />

the antenna’s element spacing is limited<br />

due to power or frequency.<br />

Summary<br />

<strong>Raytheon</strong>’s panel AESAs will revolutionize<br />

the way RF sensors are packaged and integrated,<br />

enabling new capabilities affordably<br />

across many applications from lowpower<br />

ground-based, to high-performance<br />

low-observable airborne, to very large missile<br />

defense and surveillance sensors.<br />

Mike Sarcione<br />

michael_g_sarcione@raytheon.com<br />

AESLA is a trademark of <strong>Raytheon</strong> Company.<br />

onTechnology<br />

<strong>Raytheon</strong> Mission<br />

Architecture<br />

Program (RayMAP)<br />

Provides a Foundation<br />

for System Success<br />

More than ever, today's rapidly changing<br />

and increasingly complex systems<br />

demand quality architecture development.<br />

This benefits customers and developers by<br />

helping to define the problem space, validating<br />

needs and requirements, and providing<br />

a platform for sharing ideas.<br />

Architecture also aids in system development<br />

by concisely and comprehensively<br />

describing the system’s structure to the<br />

developers and maintenance engineers,<br />

and it facilitates technology transfer by fostering<br />

reuse of domain architectural styles<br />

and patterns. Careful architecture development<br />

helps ensure that detailed design and<br />

implementation maximize requirements<br />

compliance, but minimize cost and schedule.<br />

Inadequate attention to architecture,<br />

however, can harm system performance<br />

and inhibit reusability, interoperability and<br />

other areas of customer concern. It makes<br />

sense, then, to maximize the effectiveness<br />

of a system’s architectural foundation.<br />

While <strong>Raytheon</strong> has embraced the architecture<br />

discipline for some time, <strong>Raytheon</strong><br />

leadership also recognizes the need for a<br />

unified, cross-business approach to capture<br />

and leverage best architecture practices. A<br />

corporate-funded enterprise initiative that<br />

began in 2006 formally started the process<br />

of unifying architecture across <strong>Raytheon</strong>.<br />

The <strong>Raytheon</strong> Mission Architecture Program<br />

(RayMAP) is <strong>Raytheon</strong>’s response to customer<br />

needs for architected solutions.<br />

Corporate Engineering will take over the<br />

sustainment of RayMAP starting in <strong>2009</strong>.<br />

RayMAP includes the following six key elements,<br />

which collectively lay the foundation<br />

for solid, disciplined architecture capabilities<br />

across <strong>Raytheon</strong>.