Raytheon Technology Today 2011 Issue 1

Raytheon Technology Today 2011 Issue 1

Raytheon Technology Today 2011 Issue 1

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

forcing the cantilever to spring back and oscillate<br />

around its initial equilibrium position.<br />

This approach allows for the continuous<br />

transfer of energy from mechanical to<br />

electrical, generated by the vibrating piezoelectric-based<br />

cantilever. As the platform<br />

continues to oscillate, the piezoelectric-<br />

attached structure generates useful electricity<br />

that can be harvested for various<br />

applications. Its oscillation frequency can<br />

be fine-tuned by modifying the length<br />

of the cantilever and the strength of the<br />

radiation source. Depending on its intended<br />

application, the output of this device can be<br />

utilized as a source of tunable rapid current<br />

spikes, or filtered to produce a continuous<br />

DC output stream.<br />

An approach to implementing radio frequency<br />

identification (RFID), for example, is<br />

based on a modification of the self-reciprocating<br />

cantilever design described above.<br />

Tin, et al. 2 , report the generation of 264<br />

MHz wireless signals induced directly by<br />

vibration of the cantilever. Another RFID design<br />

employs a surface acoustic wave (SAW)<br />

resonator connected to and excited by the<br />

vibrating cantilever. This concept has been<br />

shown to produce a frequency modulation<br />

found useful as a CMOS-compatible wireless<br />

communications beacon. The authors<br />

report on the design of a SAW transponder<br />

that can transmit an RF signal at 800 microwatts,<br />

with a 10 microsecond pulse<br />

duration, every three minutes at a frequency<br />

locked to a 315 megahertz SAW resonator. 3<br />

In addition to RFID, <strong>Raytheon</strong> is pursuing<br />

applications such as power sources for<br />

autonomous sensors and long-lived, miniature,<br />

wireless transmitters. The benefit<br />

provided to these applications is long-term<br />

unattended, reliable operation achieved<br />

using devices that contain embedded high<br />

energy density betavoltaic power sources. •<br />

Bernard Harris<br />

1 C. Honsberg, et al., ”GaN Betavoltaic Energy Converters,” IEEE<br />

Photovoltaics Specialist Conference. Orlando, Fla., 2005.<br />

2 S. Tin, et al.,”Self-Powered Discharge-Based Wireless<br />

Transmitter,” IEEE International Conference on<br />

MicroElectroMechanical Systems, 2008.<br />

3 S. Tin and A. Lal, “A radioisotope-powered surface acoustic wave<br />

transponder,” J. Micromech. Microeng., 19 (2009).<br />

Creating Compact, Reliable<br />

and Clean Power With Fuel Cell<br />

<strong>Technology</strong><br />

Feature<br />

The demand for compact, reliable and clean power is an important driver and constraint<br />

for large and small systems. Rapid technological advances have been made in<br />

fuel cells, which are of interest to <strong>Raytheon</strong> and our customers as a more effective<br />

source of power for key products and as a more sustainable source of power for facilities<br />

and large-scale systems.<br />

<strong>Raytheon</strong> is employing new developments in fuel cell technology that are likely to be part of<br />

the next generation of power solutions.<br />

How Fuel Cells Work: The Basics<br />

Fuel cells produce direct current (DC) electrical power through an electrochemical reaction<br />

in which a fuel (hydrogen or a hydrocarbon) is oxidized, typically with pure oxygen or air.<br />

Some designs use chemicals such as chlorine as the oxidizing agent. A fuel cell consists of<br />

two electrodes, the anode and cathode, separated by an electrolyte. The electrolyte may<br />

be liquid, such as an aqueous alkaline solution, or solid, such as those using polymer membranes<br />

or solid oxide fuel cells (SOFC). This distinction defines the two basic classes of fuel<br />

cells — liquid and solid — with numerous variants of each.<br />

Fuel cells are distinct from batteries, the other major class of electrochemical power cells.<br />

A fuel cell is a thermodynamically open system into which fuel is continuously injected to<br />

generate power. In contrast, a battery is a closed system that stores power, though many<br />

battery types can have power added through recharging.<br />

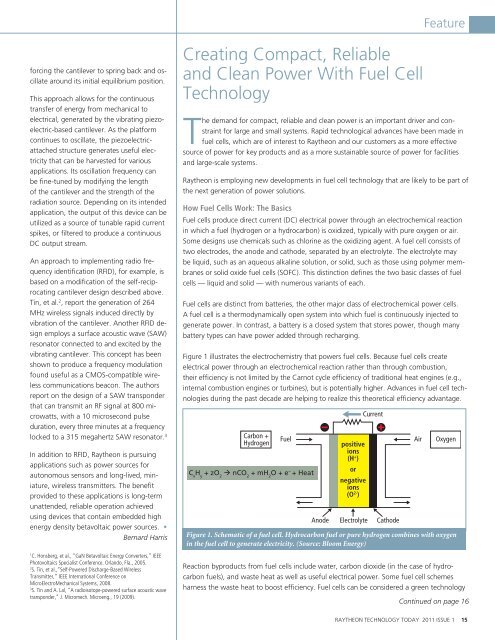

Figure 1 illustrates the electrochemistry that powers fuel cells. Because fuel cells create<br />

electrical power through an electrochemical reaction rather than through combustion,<br />

their efficiency is not limited by the Carnot cycle efficiency of traditional heat engines (e.g.,<br />

internal combustion engines or turbines), but is potentially higher. Advances in fuel cell technologies<br />

during the past decade are helping to realize this theoretical efficiency advantage.<br />

Anode<br />

Current<br />

Carbon +<br />

Hydrogen<br />

C H + zO � nCO + mH O + e x y 2 2 2 − Fuel<br />

positive<br />

ions<br />

(H<br />

Air<br />

+ Heat<br />

+ )<br />

or<br />

negative<br />

ions<br />

(O2- )<br />

Electrolyte Cathode<br />

Oxygen<br />

Figure 1. Schematic of a fuel cell. Hydrocarbon fuel or pure hydrogen combines with oxygen<br />

in the fuel cell to generate electricity. (Source: Bloom Energy)<br />

Reaction byproducts from fuel cells include water, carbon dioxide (in the case of hydrocarbon<br />

fuels), and waste heat as well as useful electrical power. Some fuel cell schemes<br />

harness the waste heat to boost efficiency. Fuel cells can be considered a green technology<br />

Continued on page 16<br />

RAYTHEON TECHNOLOGY TODAY <strong>2011</strong> ISSUE 1 15