Cooling/Casting - Spraying Systems Co.

Cooling/Casting - Spraying Systems Co.

Cooling/Casting - Spraying Systems Co.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

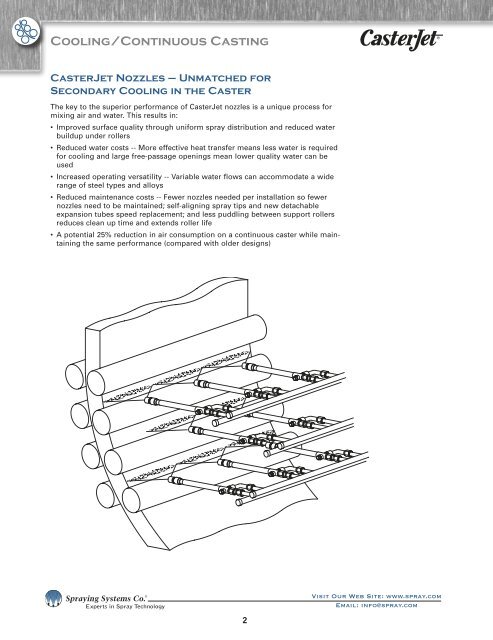

<strong><strong>Co</strong>oling</strong>/<strong>Co</strong>ntinuous <strong>Casting</strong>CasterJet Nozzles – Unmatched forSecondary <strong><strong>Co</strong>oling</strong> in the CasterThe key to the superior performance of CasterJet nozzles is a unique process formixing air and water. This results in:• Improved surface quality through uniform spray distribution and reduced waterbuildup under rollers• Reduced water costs -- More effective heat transfer means less water is requiredfor cooling and large free-passage openings mean lower quality water can beused• Increased operating versatility -- Variable water flows can accommodate a widerange of steel types and alloys• Reduced maintenance costs -- Fewer nozzles needed per installation so fewernozzles need to be maintained; self-aligning spray tips and new detachableexpansion tubes speed replacement; and less puddling between support rollersreduces clean up time and extends roller life• A potential 25% reduction in air consumption on a continuous caster while maintainingthe same performance (compared with older designs)2