Underground Ground Control Major Hazard Standard - MIRMgate

Underground Ground Control Major Hazard Standard - MIRMgate

Underground Ground Control Major Hazard Standard - MIRMgate

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

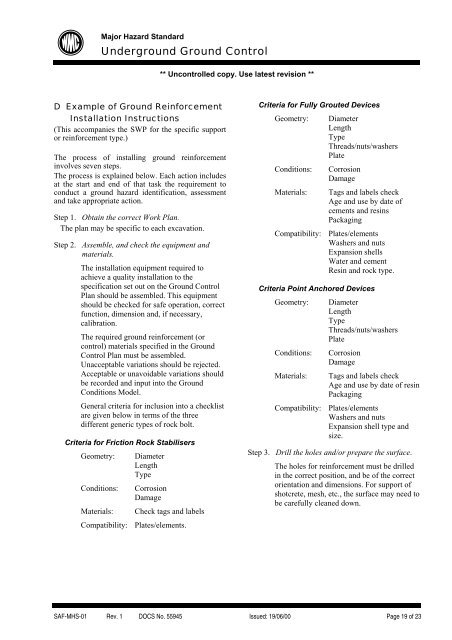

<strong>Major</strong> <strong>Hazard</strong> <strong>Standard</strong><strong>Underground</strong> <strong>Ground</strong> <strong>Control</strong>** Uncontrolled copy. Use latest revision **D Example of <strong>Ground</strong> ReinforcementInstallation Instructions(This accompanies the SWP for the specific supportor reinforcement type.)The process of installing ground reinforcementinvolves seven steps.The process is explained below. Each action includesat the start and end of that task the requirement toconduct a ground hazard identification, assessmentand take appropriate action.Step 1. Obtain the correct Work Plan.The plan may be specific to each excavation.Step 2. Assemble, and check the equipment andmaterials.The installation equipment required toachieve a quality installation to thespecification set out on the <strong>Ground</strong> <strong>Control</strong>Plan should be assembled. This equipmentshould be checked for safe operation, correctfunction, dimension and, if necessary,calibration.The required ground reinforcement (orcontrol) materials specified in the <strong>Ground</strong><strong>Control</strong> Plan must be assembled.Unacceptable variations should be rejected.Acceptable or unavoidable variations shouldbe recorded and input into the <strong>Ground</strong>Conditions Model.General criteria for inclusion into a checklistare given below in terms of the threedifferent generic types of rock bolt.Criteria for Friction Rock StabilisersGeometry: DiameterLengthTypeConditions: CorrosionDamageMaterials: Check tags and labelsCompatibility: Plates/elements.Criteria for Fully Grouted DevicesGeometry: DiameterLengthTypeThreads/nuts/washersPlateConditions: CorrosionDamageMaterials: Tags and labels checkAge and use by date ofcements and resinsPackagingCompatibility: Plates/elementsWashers and nutsExpansion shellsWater and cementResin and rock type.Criteria Point Anchored DevicesGeometry: DiameterLengthTypeThreads/nuts/washersPlateConditions: CorrosionDamageMaterials: Tags and labels checkAge and use by date of resinPackagingCompatibility: Plates/elementsWashers and nutsExpansion shell type andsize.Step 3. Drill the holes and/or prepare the surface.The holes for reinforcement must be drilledin the correct position, and be of the correctorientation and dimensions. For support ofshotcrete, mesh, etc., the surface may need tobe carefully cleaned down.SAF-MHS-01 Rev. 1 DOCS No. 55945 Issued: 19/06/00 Page 19 of 23