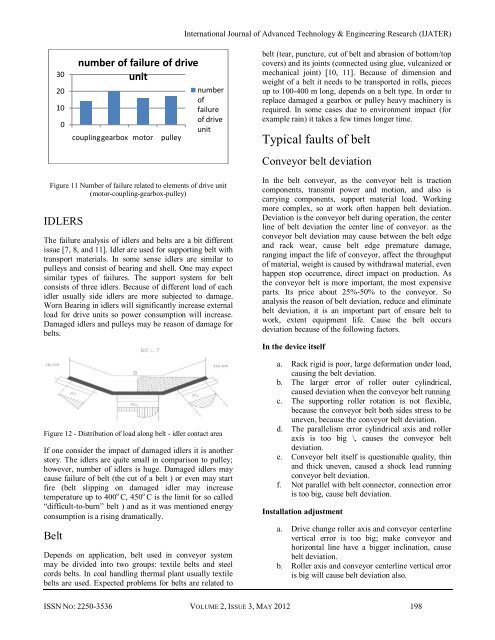

International Journal <strong>of</strong> Advanced Technology & Eng<strong>in</strong>eer<strong>in</strong>g Research (IJATER)3020100number <strong>of</strong> failure <strong>of</strong> driveunitcoupl<strong>in</strong>ggearbox motorpulleynumber<strong>of</strong>failure<strong>of</strong> driveunitbelt (tear, puncture, cut <strong>of</strong> belt and abrasion <strong>of</strong> bottom/topcovers) and its jo<strong>in</strong>ts (connected us<strong>in</strong>g glue, vulcanized ormechanical jo<strong>in</strong>t) [10, 11]. Because <strong>of</strong> dimension andweight <strong>of</strong> a belt it needs to be transported <strong>in</strong> rolls, piecesup to 100-400 m long, depends on a belt type. In order toreplace damaged a gearbox or pulley heavy mach<strong>in</strong>ery isrequired. In some cases due to environment impact (forexample ra<strong>in</strong>) it takes a few times longer time.Typical faults <strong>of</strong> belt<strong>Conveyor</strong> belt deviationFigure 11 Number <strong>of</strong> failure related to elements <strong>of</strong> drive unit(motor-coupl<strong>in</strong>g-gearbox-pulley)IDLERSThe failure analysis <strong>of</strong> idlers and belts are a bit differentissue [7, 8, and 11]. Idler are used for support<strong>in</strong>g belt withtransport materials. In some sense idlers are similar topulleys and consist <strong>of</strong> bear<strong>in</strong>g and shell. One may expectsimilar types <strong>of</strong> failures. The support <strong>system</strong> for beltconsists <strong>of</strong> three idlers. Because <strong>of</strong> different load <strong>of</strong> eachidler usually side idlers are more subjected to damage.Worn Bear<strong>in</strong>g <strong>in</strong> idlers will significantly <strong>in</strong>crease externalload for drive units so power consumption will <strong>in</strong>crease.Damaged idlers and pulleys may be reason <strong>of</strong> damage forbelts.Figure 12 - Distribution <strong>of</strong> load along belt - idler contact areaIf one consider the impact <strong>of</strong> damaged idlers it is anotherstory. The idlers are quite small <strong>in</strong> comparison to pulley;however, number <strong>of</strong> idlers is huge. Damaged idlers maycause failure <strong>of</strong> belt (the cut <strong>of</strong> a belt ) or even may startfire (belt slipp<strong>in</strong>g on damaged idler may <strong>in</strong>creasetemperature up to 400 o C, 450 o C is the limit for so called“difficult-to-burn” belt ) and as it was mentioned energyconsumption is a ris<strong>in</strong>g dramatically.<strong>Belt</strong>Depends on application, belt used <strong>in</strong> conveyor <strong>system</strong>may be divided <strong>in</strong>to two groups: textile belts and steelcords belts. In coal handl<strong>in</strong>g thermal plant usually textilebelts are used. Expected problems for belts are related toIn the belt conveyor, as the conveyor belt is tractioncomponents, transmit power and motion, and also iscarry<strong>in</strong>g components, support material load. Work<strong>in</strong>gmore complex, so at work <strong>of</strong>ten happen belt deviation.Deviation is the conveyor belt dur<strong>in</strong>g operation, the centerl<strong>in</strong>e <strong>of</strong> belt deviation the center l<strong>in</strong>e <strong>of</strong> conveyor. as theconveyor belt deviation may cause between the belt edgeand rack wear, cause belt edge premature damage,rang<strong>in</strong>g impact the life <strong>of</strong> conveyor, affect the throughput<strong>of</strong> material, weight is caused by withdrawal material, evenhappen stop occurrence, direct impact on production. Asthe conveyor belt is more important, the most expensiveparts. Its price about 25%-50% to the conveyor. Soanalysis the reason <strong>of</strong> belt deviation, reduce and elim<strong>in</strong>atebelt deviation, it is an important part <strong>of</strong> ensure belt towork, extent equipment life. Cause the belt occursdeviation because <strong>of</strong> the follow<strong>in</strong>g factors.In the device itselfa. Rack rigid is poor, large deformation under load,caus<strong>in</strong>g the belt deviation.b. The larger error <strong>of</strong> roller outer cyl<strong>in</strong>drical,caused deviation when the conveyor belt runn<strong>in</strong>gc. The support<strong>in</strong>g roller rotation is not flexible,because the conveyor belt both sides stress to beuneven, because the conveyor belt deviation.d. The parallelism error cyl<strong>in</strong>drical axis and rolleraxis is too big \, causes the conveyor beltdeviation.e. <strong>Conveyor</strong> belt itself is questionable quality, th<strong>in</strong>and thick uneven, caused a shock lead runn<strong>in</strong>gconveyor belt deviation.f. Not parallel with belt connector, connection erroris too big, cause belt deviation.Installation adjustmenta. Drive change roller axis and conveyor centerl<strong>in</strong>evertical error is too big; make conveyor andhorizontal l<strong>in</strong>e have a bigger <strong>in</strong>cl<strong>in</strong>ation, causebelt deviation.b. Roller axis and conveyor centerl<strong>in</strong>e vertical erroris big will cause belt deviation also.ISSN NO: 2250-3536 VOLUME 2, ISSUE 3, MAY 2012 198

International Journal <strong>of</strong> Advanced Technology & Eng<strong>in</strong>eer<strong>in</strong>g Research (IJATER)c. The connection strength between rack andground is not enough, the rack unstable, caus<strong>in</strong>gbelt deviation.d. The feed<strong>in</strong>g plate <strong>of</strong> discharge through andimproperly located, both sides <strong>of</strong> the conveyorbelt uneven force cause belt deviation.With ma<strong>in</strong>tenancea. The clean<strong>in</strong>g performance <strong>of</strong> sweeper is poor;make the roller cyl<strong>in</strong>drical diameter local<strong>in</strong>creases.b. Feed<strong>in</strong>g mouth location is wrong, so that thematerial partial load on the conveyor belt, causebelt deviation.c. Poor ma<strong>in</strong>tenance and improper adjustment,result<strong>in</strong>g <strong>in</strong> the conveyor belt deviation.d. For the steel cord belt, as the manufacture <strong>of</strong>steel cord is uneven force, so that a deviationoccurs <strong>in</strong> the operation, or a strong difference <strong>of</strong>belt, large elongation under load, caus<strong>in</strong>g thevibration, the belt will deviation.e. Also, the vibration <strong>of</strong> runn<strong>in</strong>g conveyor belt<strong>system</strong> can cause the deviation.f. In addition, when convey<strong>in</strong>g some viscousmaterial, make the roller, etc. bond<strong>in</strong>g material;make the cyl<strong>in</strong>drical diameter <strong>of</strong> roller part<strong>in</strong>creases, caus<strong>in</strong>g conveyor belt deviation.Measures to prevent the beltdeviation1. Due to equipment <strong>in</strong> the manufacture <strong>of</strong>conveyor belt causes the deviation, primarilythrough improved design, manufacture precisionto prevent and reduce the occurrence <strong>of</strong> conveyorbelt deviation.2. For <strong>in</strong>stallation adjust improper and daily usecauses deviation, ma<strong>in</strong>ly the follow<strong>in</strong>g aspectsshould be considered:<strong>Conveyor</strong> belt <strong>in</strong> drive roller or on rear rollersdeviation, usually by adjust<strong>in</strong>g the position <strong>of</strong> rollerbear<strong>in</strong>g ways to elim<strong>in</strong>ate,a. The longitud<strong>in</strong>al centerl<strong>in</strong>e <strong>of</strong> the roller rotationaxis and conveyor is not perpendicular, result<strong>in</strong>g<strong>in</strong> the conveyor belt one side loose and othertight, belt move from the tight side to the looseside, occurs deviation phenomenon. Should beadjusted bear<strong>in</strong>g position <strong>of</strong> tighten deviationside. Make horizontal pull <strong>of</strong> belt equal,elim<strong>in</strong>ate deviation. When tail roller device bothsides screw rod are not equal, result<strong>in</strong>g <strong>in</strong> causedby imbalance.b. Cyl<strong>in</strong>drical axis is not horizontal, at both endsbear<strong>in</strong>g <strong>of</strong> height difference is cause anotherreason <strong>of</strong> head or tail deviation. At this po<strong>in</strong>t, atboth ends roller bear<strong>in</strong>g should add subtractshims way to level<strong>in</strong>g roller axis, to elim<strong>in</strong>ateconveyor belt deviation.c. Roller surface adhesion material, equivalent to<strong>in</strong>creas<strong>in</strong>g the roller local diameter, will causethe conveyor belt deviation, should strengthenempty segment clean<strong>in</strong>g <strong>of</strong> conveyor belt toreduce the adhesive material or dustaccumulation on the conveyor belt. In addition,the conveyor belt between the nose and tail partsdeviation, called central or local deviation. Suchdeviation reasons are more complex, it is withthe conveyor belt along device exposure to arelationship. Need a detailed analysis for specificissues. Us<strong>in</strong>g the follow<strong>in</strong>g method can resolvethese issues.A. Load or no- load branch roller axis with theconveyor belt runn<strong>in</strong>g centerl<strong>in</strong>e is notperpendicular, caus<strong>in</strong>g tape at the rollerdeviation. Deviation ends should adjustmentto the conveyor belt runn<strong>in</strong>g direction. Atthis <strong>of</strong>ten need to adjust the adjacent groups<strong>of</strong> order to achieve the purpose <strong>of</strong>elim<strong>in</strong>at<strong>in</strong>g deviation; adjust<strong>in</strong>g deviationangle should not be too big.B. <strong>Conveyor</strong> belt jo<strong>in</strong>t with the tape centerl<strong>in</strong>e(trumpet) is not perpendicular, to cause thedeviation, should improved <strong>in</strong>stallationconnection accuracy to elim<strong>in</strong>ate deviation.C. If material loaded on the conveyer belt isstraight; make the material block and weightdistribution along bandwidth directiondistribution serious <strong>in</strong>equality, causedeviation, through adjustment blank<strong>in</strong>g tubeand skirt plate location method to beelim<strong>in</strong>ated.Recently, it was suggested that the method <strong>of</strong>application film for transfer partial conveyor beltbecause <strong>of</strong> high manufactur<strong>in</strong>g costs and sometechnical problems not well solved, makes thismethod very difficult to promote the use.Solutionsa. In the roller manufactur<strong>in</strong>g process guarantee theaccuracy requirements, for example, press<strong>in</strong>g bear<strong>in</strong>gbore to achieve three precision, tubes at both ends <strong>of</strong>dimensional tolerances, concentricity and ovality mustmeet national standards. The products have strictquality <strong>in</strong>spection to ensure that all products qualified.Sealed lubrication, <strong>in</strong> addition to manufactur<strong>in</strong>g qualityassurance, go with good lubricat<strong>in</strong>g materials. Such asuse <strong>of</strong> lithium-based grease, can improve thelubrication <strong>of</strong> bear<strong>in</strong>g which extend the life <strong>of</strong> theroller is necessary.ISSN NO: 2250-3536 VOLUME 2, ISSUE 3, MAY 2012 199