Retaining Walls Product Guide - Shaw Precast Solutions

Retaining Walls Product Guide - Shaw Precast Solutions

Retaining Walls Product Guide - Shaw Precast Solutions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

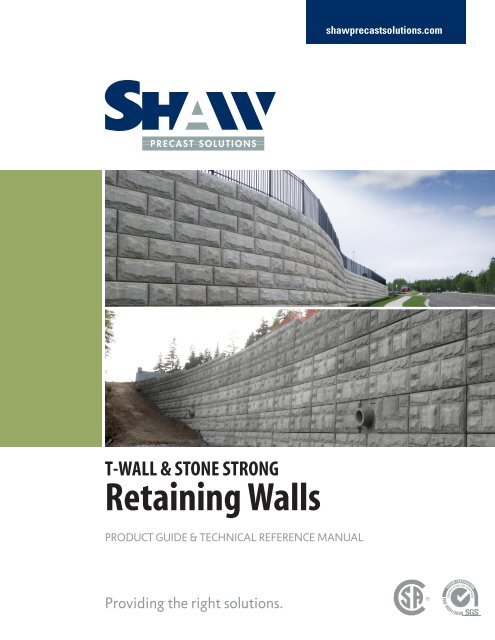

shawprecastsolutions.comT-WALL & STONE STRONG<strong>Retaining</strong> <strong>Walls</strong>PRODUCT GUIDE & TECHNICAL REFERENCE MANUALProviding the right solutions.

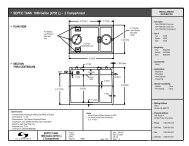

T-WALLT-WALLThe T-WALL‚ <strong>Retaining</strong> Wall System is a gravity structureconstructed of individual precast T-WALL‚ units. EachT-WALL; unit consists of a front face panel and a stem, whichextends back into and engages the soil. The standard height forthe face panel and stem is 750mm. The face panel typically hasa width of 1500mm. Stem lengths vary and are selected on thebasis of wall height and stability.The design for each T-WALL‚ structure is carried out byProfessional Engineers as part of the wall supply service. Thewall structure is checked to ensure adequate safety factors foroverturning, pullout and sliding. The bearing pressure alongthe underside of the wall is calculated using the Meyerhofmethod and checked against the allowable bearing capacity.Stamped shop drawings are available for each projectREVISED November 12, 20122 SHAW PRECAST SOLUTIONS | RETAINING WALLS > T-WALL

shawprecastsolutions.comT-WALLThe modular nature of the T-WALL‚ unit provides flexibilityfor wall layout and allows on-site modifications whenunexpected conditions such as rock outcrops or existingservices are encountered. <strong>Shaw</strong> <strong>Precast</strong> <strong>Solutions</strong> provides thejoint materials, filter fabric, special lifting devices and all othermaterials required for complete on-site wall erection.<strong>Shaw</strong> <strong>Precast</strong> <strong>Solutions</strong> offers one on one consultation forlayout and design of T-WALL‚ projects. We will assist on theproject from the conceptual stage, through to final design andon-site installation.APPLICATIONST-WALL‚ provides cost effective solutions to a number of siteconditions commonly encountered in commercial, industrialand public works. Typical applications include:• Highways, roads, and parking lots• Bridge abutments and wingwalls• Site development• Bank stabilization• <strong>Retaining</strong> wallsStem Length(mm)T-WALL® UNIT WEIGHTSWeight(kg)1219 7261829 8392438 9533048 10663658 11794267 13154877 14295486 15426096 1656T-WALLSHAW PRECAST SOLUTIONS | RETAINING WALLS > T-WALL 3

T-WALL CONSTRUCTIONPROCEDURESAll the components required for complete on-site erectionof a T-WALL‚ structure are supplied and delivered to siteby <strong>Shaw</strong> <strong>Precast</strong> <strong>Solutions</strong>. A <strong>Shaw</strong> <strong>Precast</strong> <strong>Solutions</strong>representative is available at the start of wall erection toprovide hands on technical assistance. An overview of thestraightforward construction steps for a T-WALL‚ structurefollows:T-WALLADVANTAGESA T-WALL‚ STRUCTURE WILL PROVIDE:A HIGH QUALITY PRODUCT: Fabrication of the T-WALL‚units by experienced crews in a controlled environmentensures a high quality product. Units are cast in the plantunder comprehensive quality control eliminating thedrawbacks imposed by weather and site conditions.T-WALLFOUNDATION PREPARATION: The foundation is preparedby grading level and proof rolling the area where the T-WALL‚units are to be placed. Unsuitable materials below subgradeare removed and replaced with compacted granular backfill.LEVELING PAD: A nonstructural, non-reinforced concreteleveling pad is placed along the line of the wall face to providea working platform for placement of the T-WALL‚ units. Achalk line is established on the leveling pad to mark the frontface of the wall.ECONOMY: T-WALL‚ structures are cost competitive withtraditional cast in place retaining walls.QUICK AND EASY ON-SITE INSTALLATION: Theinstallation of a T-WALL‚ structure involves preparation ofthe site, placement and backfilling of wall units. Dependingon project size, preparation of the site may be completed in amatter of hours. Placement of wall units can be carried out byon site equipment such as a large excavator and is a straightforward and rapid operation.FIRST T-WALL‚ COURSE: Staring at a fixed point such as acorner of the wall or an existing structure the first course ofunits is set using the chalk line on the leveling pad to line upthe front faces.BACKFILLING: Prior to initial backfilling a 300mm widefilter fabric is cut into lengths equal to the height of thewall at each vertical joint. These strips are placed across thevertical joints between the units to prevent migration of thebackfill material through the joints. The Backfill material isdumped directly on the tops of the stems to fill both sidesequally and prevent lateral movement of the unit. The backfillis compacted in 300mm lifts.SUBSEQUENT T-WALL‚ COURSES: Joint material is placedin the horizontal joints between the units at the front face toprevent concrete to concrete contact and to act as a gasketagainst loss of fines through these joints. <strong>Precast</strong> shear keysare placed in the blockouts in the top of the stems to providean alignment guide and prevent movement of the units duringbackfillling. Backfilling and compaction of each lift of T-WALL‚units is completed before the next course is started.SCHEDULE: <strong>Precast</strong> fabrication of T-WALL‚ reduces theamount of work on-site and possible impact of weather onproject schedules. The wall units can be installed, backfilledand placed into service immediately upon delivery to the site.T-WALL‚ units can be preordered to allow projects to proceedon-site in early spring.REDUCED WATER CONTROL COSTS: On projects wherethe work site involves a water course, a precast structureeliminates the need to maintain a dry site for the entireduration of the project reducing water control requirementsand costs.DURABILITY: <strong>Precast</strong> concrete products have all thedurability advantages of high quality concrete, without theconcern of breakdown of protective coatings, corrosion orother problems associated with other materials.EASE OF INSPECTION: The Purchaser has the option toinspect the T-WALL‚ units at the plant prior to delivery. Withcast in place structures, deficiencies such as low concretestrength represent a costly problem as the product is alreadyin placeREVISED November 12, 20124 SHAW PRECAST SOLUTIONS | RETAINING WALLS > T-WALL

shawprecastsolutions.comVERTICAL T-WALLS – LEVEL EMBANKMENTCourseDistancefrom top of wall(mm)WALL HEIGHT (mm)2286 3048 3810 4572 5334 6096 6858 7620 8382STEM LENGTH (mm)1 762 1219 1219 1219 1219 1219 1219 1219 1219 12192 1524 1219 1219 1219 1219 1219 1219 1219 1219 12193 2286 1829 1829 1829 1829 1829 1829 1829 1829 18294 3048 1829 1829 1829 1829 1829 1829 1829 18295 3810 2438 2438 2438 2438 2438 2438 24386 4572 3048 3048 3048 3048 3048 30487 5334 3048 3048 3048 3048 30488 6096 3658 3658 3658 36589 6858 4267 3658 365810 7620 4267 426711 8382 4877T-WALLVERTICAL T-WALLS – SLOPED EMBANKMENTCourseDistancefrom top of wall(mm)WALL HEIGHT (mm)2286 3048 3810 4572 5334 6096 6858 7620 8382STEM LENGTH (mm)1 762 1219 1219 1219 1219 1219 1219 1219 1219 12192 1524 1219 1219 1219 1219 1219 1219 1219 1219 12193 2286 1829 1829 1829 1829 1829 1829 1829 1829 18294 3048 2438 2438 2438 2438 2438 2438 2438 24385 3810 3048 3048 2438 2438 2438 2438 24386 4572 3658 3048 3048 3048 3048 30487 5334 3658 3658 3658 3658 36588 6096 4267 4267 4267 42679 6858 4877 4877 487710 7620 5486 548611 8382 6096SHAW PRECAST SOLUTIONS | RETAINING WALLS > T-WALL 5

T-WALLREVISED November 12, 20126 SHAW PRECAST SOLUTIONS | RETAINING WALLS > T-WALL

shawprecastsolutions.comSTONE ® STRONG SYSTEMSSTONE® STRONG SYSTEMSFive years since <strong>Shaw</strong> <strong>Precast</strong> <strong>Solutions</strong> launched Stone StrongSystems, the retaining wall product that transformed the wayboth designers and property developers evaluate and chooseretaining wall block. At 24 square feet per unit, the StoneStrong block is the largest precast block in the marketplace,twice as large as any competitive product. Placement of24 square feet of wall area every time you set one block –compared to many multiple sections of any other system,allowing you to build a substantial wall very quickly. Theblocks’ tapered sides also make it easy to create both straightand winding designs, even convex, concave, and circulardesigns.Since 2007, sales have grown enormously. Now you cansee Stone Strong everywhere you turn – from highwaysto railroads to shoreline preservation projects. “Recentinstallations include multi-unit apartment and condo sites,subdivision developments, and highway twinning projects.The big news this year is the launch of the new 24-62 and24-86 blocks making the Stone Strong System even morecompetitive in the marketplace. Giving new meaning to theword huge, these new forms have double the depth – at threefeet high, eight feet long, and seven feet deep, the new blocksweigh more than 3,500 kilograms This means that enormousfree-standing gravity walls can now be built. In the recentpast, if a wall was higher than ten feet, expensive tie-backsor geo-grid systems (reinforcement with woven polyesteror polypropylene mesh) would need to be used. These newlarge base blocks eliminate those expensive requirements.Contractors and customers are not only saving money, butthe actual construction of these gravity walls is much faster. Awall recently completed in Lower Sackville that is 18 feet highand is totally a gravity installation. Due to the site propertyboundaries, Stone Strong was considered the product ofchoice. No other wall system could offer that height withoutencroaching on neighboring properties. Without the needfor expensive tie-back systems, it allowed the owner andcontractor to eliminate the need for over-excavation. Utilizingthe new base block units, this gravity wall was constructedquickly and efficiently.As land steadily increases in price and developers are lookingto get the most value out of every site, retaining walls continueto be a creative way to use all the available space and workaround topographical challenges. Building bigger, higher, andlonger walls can be part of the solution.If you require a wall that is economical, quick and easy toinstall, readily available, and comes with a supplier that canprovide design-build expertise we suggest you consider <strong>Shaw</strong><strong>Precast</strong> <strong>Solutions</strong> and the Stone Strong System for your nextretaining wall application.SHAW PRECAST SOLUTIONS | RETAINING WALLS > STONE STRONG SYSTEMS 7

STONE® STRONG SYSTEMSREVISED November 12, 20128 SHAW PRECAST SOLUTIONS | RETAINING WALLS > STONE STRONG SYSTEMS

shawprecastsolutions.comSTONE® STRONG SYSTEMSSHAW PRECAST SOLUTIONS | RETAINING WALLS > STONE STRONG SYSTEMS 9