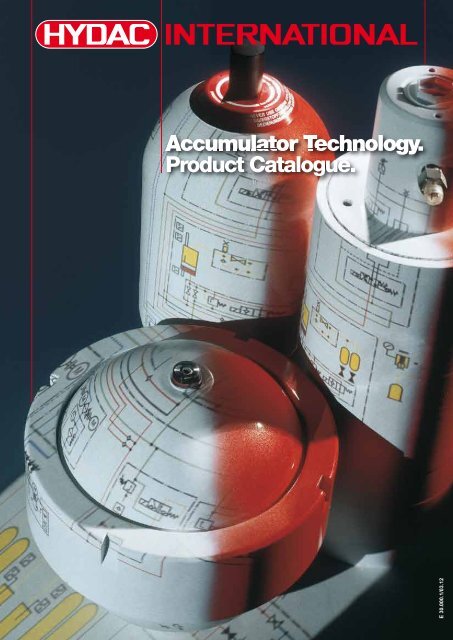

Accumulator Technology. Product Catalogue. - Sea

Accumulator Technology. Product Catalogue. - Sea

Accumulator Technology. Product Catalogue. - Sea

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Accumulator</strong><strong>Technology</strong>.<strong>Product</strong> <strong>Catalogue</strong>.E 30.000.1/03.12

1. HYDAC ACCUMULATOR TECHNOLOGYFLUID ENGINEERING EFFICIENCY THROUGH ENERGY MANAGEMENT.HYDAC <strong>Accumulator</strong> <strong>Technology</strong> has over45 years' experience in research &development, design and production ofHydac accumulators.Bladder, piston, diaphragm and metalbellows accumulators from HYDACtogether form an unbeatable range and ascomponents or units, support hydraulicsystems in almost all sectors.The main applications of our accumulatorsare:• zEnergy storage,• zEmergency and safety functions,• zDamping of vibrations, fluctuations,pulsations (pulsation damper), shocks(shock absorber) and noise (silencer),• zSuction flow stabilisation,• zMedia separation,• zVolume and leakage oil adjustment,• zWeight equalization,• zEnergy recovery.Using accumulators improves theperformance of the whole system and indetail this has the following benefits:• zImprovement in the functions• zIncrease in service life• zReduction in operating and maintenancecosts• zReduction in pulsations and noiseOn the one hand, this means greatersafety and comfort for operator andmachine.On the other hand, HYDAC accumulatorsenable efficient working in all applications.Basic criteria, such as:• zDesign pressure,• zDesign temperature,• zFluid displacement volume,• zDischarge / Charging velocity,• zFluid,• zAcceptance specifications and also• zMounting optionsare important parameters required forsizing the correct accumulator.In addition the knowledge developed byour accumulator specialists will help toselect the right type of accumulator. Thecomprehensive range of HYDACaccessories simplifies installation andmaintenance according to thespecification.2. QUALITYQuality, safety and reliability are paramountfor all HYDAC accumulator components.They comply with the current regulations(or standards) for pressure vessels in theindividual countries of installation.In taking delivery of a HYDAC Hydraulic<strong>Accumulator</strong> therefore, the customer isassured of a high-quality accumulatorproduct which can be used in everycountry in the world, depending on thecertification.For more details, please turn to Section 4.All the processes involved, fromdevelopment, engineering and productionto approval and delivery are defined byHYDAC's certified management systemand the relevant international accreditationfor the manufacture of pressure vessels.In conjunction with the customer servicedepartment at HYDAC's headquarters,service is possible worldwide.HYDAC's worldwide distributor networkmeans that trained staff are close at handto help our customers.This ensures that HYDAC customers havethe support of an experienced workforceboth before and after sale.E 3.000.12/03.122

CONTENTSPage<strong>Catalogue</strong>sectionPage1. HYDAC <strong>Accumulator</strong> <strong>Technology</strong> 2 E 3.000 22. Quality 23. Safety information 44. Regulations 55. <strong>Product</strong> overview 6 – 85.1. BLADDER ACCUMULATORS5.1.1 Standard E 3.201 195.1.2 Low pressure E 3.202 275.1.3 High pressure E 3.203 355.2. PISTON ACCUMULATORS5.2.1 Standard E 3.301 395.2.2 Series SK280 E 3.303 515.3. DIAPHRAGM ACCUMULATORS E 3.100 555.4. Metal bellows accumulators E 3.304 615.5. Hydraulic dampers E 3.701 675.6. Special accumulators5.7. <strong>Accumulator</strong> stations E 3.653 855.8. <strong>Accumulator</strong> accessories5.8.1 Hydraulic accumulators with back-up nitrogen bottles E 3.553 915.8.2 Universal charging and testing unit E 3.501 975.8.3 Safety and shut-off block E 3.551 1075.8.4 Safety equipment for hydraulic accumulators E 3.552 1295.8.5 Supports for hydraulic accumulators E 3.502 1355.8.6 ACCUSET SB E 3.503 1436. Industries and applications 9 – 107. / 8. Website / Specification Forms 10 – 169. Sizing 17 – 1810. NOTE 18E 3.000.12/03.123

3. SAFETY INFORMATIONHydraulic accumulators are pressurevessels as defined in the PressureEquipment Directive 97/23/EC. They areclosed vessels which are designed andbuilt to store pressurized fluids. Hydraulicaccumulators are charged with nitrogenwhich is separated from the fluid sectionby a piston, bladder or diaphragm.Hydraulic accumulators are specificallydesigned to store and then dischargepressurized fluids.The regulations for commissioning andoperating hydraulic accumulators whichare in force at the place of installationmust be observed. The plant operatoris exclusively responsible for ensuringcompliance with these regulations.Relevant instructions are provided in theOperating Manuals for our products.As regards production and placing onthe market, HYDAC has carried out acomprehensive risk assessment.Similarly the manufacturer of productsincorporating hydraulic accumulatorsmust proceed accordingly (see PressureEquipment Directive 97/23/EC) and thefollowing principles must be adhered toand in this order of priority:• zRemoval or reduction of risks, insofar asthis is reasonably possible,• zApplication of appropriate protectivemeasures against risks which cannot beeliminated,• zIf required, training of the users onthe residual risks and instructionson appropriate special measures forreducing the risks during installation and/or operation.For safe handling and operation, theoperator must draw up a risk assessmentfor the installation site, particularly incombination with other components andrisks.The resulting measures must beimplemented accordingly.In the case of fundamental risks affectinghydraulic accumulators, e.g.• zExcessive pressure and• zIncrease in temperature(in the event of fire)we already have the relevant productsavailable.On no account must any welding, solderingor mechanical work be carried out on theaccumulator shell. After the hydraulic linehas been connected it must be completelyvented. Work on systems with hydraulicaccumulators (repairs, connectingpressure gauges etc) must only be carriedout once the pressure and the fluid havebeen released.3.1. RISK OF EXCESSIVEPRESSURE<strong>Product</strong>s:Safety and shut-off block for the fluid sidein various sizes and versions.See catalogue section:• zSafety and shut-off block SAF/DSVNo. 3.551Gas safety valve and gas safety block forthe gas sideBursting discs for gas and fluid sidesSee catalogue section:• zSafety equipment for hydraulicaccumulatorsNo. 3.5523.2. RISK OF RISE INTEMPERATURE<strong>Product</strong>s:Safety and Shut-off Block with solenoidoperatedvalve (open when de-energised)in conjunction with temperature monitoring.See catalogue section:• zSafety and shut-off block SAF/DSVNo. 3.551 or on requestTemperature fusesSee catalogue section:• zSafety equipment for hydraulicaccumulatorsNo. 3.552E 3.000.12/03.124

4. PRESSUREEQUIPMENT DIRECTIVEREGULATIONSOn 29 November 1999 the Directive97/23/EC (Pressure Equipment Directive)came into force and since 29 May 2002has been exclusively binding in Europe.This directive applies to the design,manufacture, conformity assessmentand placing on the market of pressureequipment and assemblies with amaximum permitted pressure of over0.5 bar. It guarantees the free movementof goods within the European Community.EU member states must not prohibit,restrict or obstruct the placing on themarket and the commissioning of pressureequipment on account of pressure-relatedhazards, if the equipment complieswith the requirements of the pressureequipment directive and has the CE mark,and is subject to a conformity assessment.Hydraulic accumulators with a capacity ofV ≤ 1 litre, a maximum permitted pressurePS ≤ 1000 bar and a pressure capacityPS • V ≤ 50 bar • l for gases of fluid group2 (non-hazardous fluids) are subject toArticle 3, Paragraph 3 of the EuropeanPressure Equipment Directive and do notreceive the CE mark.Inspection of the equipment andinstallation, operational safety and repeattesting are controlled as before by nationallaws.The equipment relating to safety isdescribed in AD2000, ISO 4126 andEN 14359. The repeat testing intervalsare stipulated in the new German health &safety regulations.4.1. OVERSEASPressure accumulators which are installedoverseas (outside the EU), are suppliedwith the relevant test certificates requiredin the country of installation.The country of installation must be statedat the time of ordering (see code in ModelCode for the particular product: CertificateCode).HYDAC pressure vessels can be suppliedwith virtually any test certificate. Pleasenote that the permitted operating pressurecan differ from the nominal pressure.Depending on the authority, the differentmaterial requirements must be observed.4.2. Certificate code = S(U STAMP)HYDAC <strong>Technology</strong> GmbH has hadauthorization since 1985 to use theCode Symbol "U STAMP" on pressurevessels which have been manufactured inconformity with the ASME specificationsand to market these using the "NB"symbol, in the jurisdiction (area ofapplication) of “The National Board ofBoiler and Pressure Vessel Inspectors“.4.3. CERTIFICATE CODE = P(KHK certificate)For the Japanese market, HYDAC<strong>Technology</strong> GmbH has had approval asa "Self Inspecting Manufacturer" sincethe year 2000. Consequently, HYDACis authorized to manufacture and testpressure vessels for the Japanese marketand to import them into Japan.4.4. CERTIFICATE CODE = A9(MANUFACTURERLICENSING CHINA)Since 1998 HYDAC <strong>Technology</strong> GmbH hashad approval from the Chinese authority"SELO" as a manufacturer of pressurevessels and valves. HYDAC is thereforeauthorized to import welded bladder, pistonand diaphragm accumulators, and safetyvalves, into the Chinese market.In conjunction with this approval, it isabsolutely essential to provide the detailsof the end user/dealer when placing theorder.4.4. Certificate tableThe following table lists the codes used inthe model code for different countries ofinstallation.European member states Certificatecode(AKZ)AT AustriaBE BelgiumBG BulgariaCY CyprusCZ Czech RepublicDK DenmarkEE EstoniaUFI FinlandFR FranceDE GermanyGB Great BritainGR GreeceHU Hungary U 3)IE Ireland (Republic)IT ItalyLV LatviaLT LithuaniaLU LuxembourgMT MaltaNL NetherlandsPL PolandUPT PortugalRO RomaniaSK SlovakiaSI SloveniaES SpainSE SwedenRest of the WorldCertificatecode(AKZ)DZ Algeria U 3)AR Argentina U 3)AU Australia F 1)BS Bahamas E 3)BB Barbados U 3)BY Belarus A12BM Bermuda U 3)BO Bolivia U 3)BR Brazil U 3)CE Canada S1 2)CL Chile U 3)CN China A9CR Costa Rica E 3)EC Ecuador U 3)ET Egypt U 3)HK Hong Kong A9IS Iceland U 3)IN India U 3)ID Indonesia U 3)IL Israel U 3)JP Japan PJO Jordan U 3)KR Korea (Republic) U 3)KW Kuwait U 3)LB Lebanon U 3)LY Libya U 3)MY Malaysia U 3)MX Mexico U 3)NZ New Zealand TNG Nigeria U 3)NO Norway UPK Pakistan U 3)PE Peru U 3)PH Philippines U 3)PR Puerto Rico E 3)RU Russia A6SA Saudi Arabia U 3)SG Singapore U 3)ZA South Africa U 3)SD Sudan U 3)CH Switzerland USY Syria U 3)TW Taiwan U 3)TH Thailand U 3)TN Tunisia U 3)TR Turkey UUA Ukraine A10US USA S 3)YU Yugoslavia (former) U 3)1)approval required in the individual territories2)approval required in the individual provinces3)alternative certificates possibleE 3.000.12/03.125

5. PRODUCT OVERVIEW5.1. BLADDERACCUMULATORS5.1.1 StandardNominal volumes:0.5 ... 200 lPermitted operating pressure:330 ... 550 barBenefits of HYDAC bladder accumulators:• zHigh discharge speeds,• zNo pressure differential between fluidand gas sides,• zCompact, maintenance-free,• zHigh charging and dischargefrequencies.5.1.2 Low pressureNominal volumes:2.5 ... 450 lPermitted operating pressure:up to 40 bar5.1.3 High pressureNominal volumes:1 ... 54 lPermitted operating pressure:5 ... 1000 bar5.2. PISTONACCUMULATORS5.2.1 StandardNominal volumes:up to 3300 lPermitted operating pressure:210 ... 350 bar(higher pressures on request)5.2.2 Series SK280Nominal volumes:0.16 ... 5 lPermitted operating pressure:280 barBenefits of HYDAC piston accumulators:• zMinimal pressure differential betweenthe fluid and gas sides,• zLarge usable volume,• zVariable installation position,• zMonitoring of the piston position possibleusing various systems,• zParticularly suitable for back-upconfigurations,• zHigh flow rates possible,• zNo sudden discharge of gas when sealsare worn.E 3.000.12/03.125.3. DIAPHRAGMACCUMULATORS5.3.1 Diaphragm accumulatorsWeld typeNominal volumes:0.075 ... 4 lPermitted operating pressure:50 ... 330 barScrew typeNominal volumes:0.1 ... 4 lPermitted operating pressure:210 ... 750 barBenefits of HYDAC diaphragmaccumulators:• zDesign optimised for function andweight,• zChoice of installation positions,• zNo pressure differential between fluidside and gas side,• zLow-maintenance and long service life.6

5.4. METAL BELLOWSACCUMULATORS5.4.1 Metal bellows accumulatorsfor heavy diesel enginesNominal volume:3.8 lPermitted operating pressure:50 barSeries: SM50P-...other models on requestBenefits of the HYDAC metal bellowsaccumulator:• zGas-tight• zMaintenance-free• zMedia resistance over a wide range oftemperatures5.5. HYDRAULIC DAMPERS5.5.1 DampersNominal volumes:0.075 ... 450 lPermitted operating pressure:10 ... 1000 bar5.5.2 SILENCERPermitted operating pressure:330 barAdvantages of the HYDAC hydraulicdamper:• zReduces pressure pulsations,• zImproves the suction performance ofdisplacement pumps,• zPrevents pipe breaks and damage tovalves,• zProtects measuring equipment and itsfunction in the system,• zReduces noise level in hydraulicsystems,• zReduces maintenance and servicingcosts and• zExtends service life of the system.5.6. SPECIALACCUMULATORS5.6.1 Weight ReducedHydraulic <strong>Accumulator</strong>sOver 80% reduction in weightcompared to equivalentcarbon steel accumulators.The choice ranges from weight-optimizedaccumulators, e.g. by using aluminium,through to light-weight and ultra lightweightaccumulators.5.6.2 Spring accumulatorsThese are fitted with a spring.The energy is produced from the springforce, instead of gas.Further information on request.5.7. ACCUMULATORSTATIONSHYDAC supplies fully assembledaccumulator stations which are ready foroperation, complete with all the necessaryvalve controls, fittings and safetyequipment• zas an individual accumulator unit or• zin a back-up version with nitrogen bottlesto increase the effective volume.E 3.000.12/03.127

5.8. ACCUMULATORACCESSORIES5.8.1 Hydraulic accumulators withback-up nitrogen bottlesHYDAC also offers nitrogen bottles whichcan be used to back up bladder and pistonaccumulators. Nitrogen bottles used asback-ups increase the gas volume in theaccumulator.Using HYDAC nitrogen bottles providesthe following benefits:• zCost-effective expansion of theaccumulator volume and as a result• zSmaller accumulators for the same gasvolume.5.8.2 Universal charging and testingunit FPU-1Charging hose, pressure gauge andpressure reducer for HYDAC and othermakes of accumulator, up to 350 bar.Higher pressures on request5.8.3 Safety and shut-off blockSAF/DSVNominal size: 10 ... 50Permitted operating pressure:400 bar (DSV 350 bar)Pressure relief valve:Nominal width DN125.8.4 Safety equipment• zGas safety valve GSV6• zTemperature fuse• zBursting discBenefits of the HYDAC Safety and Shut-offBlock:• zMinimum of space and maintenance,• zMinimum of installation required(1 SAF replaces as a rule up to 10individual pipe connections),• zConsiderable reduction in installationtime,• zCan be adapted to different types andalso different makes of accumulator, and• zAdditional valves (pilot-operated checkvalves, flow control valves, etc).• zGas safety blockas safety equipment forHYDAC accumulator products.Approval according to Pressure EquipmentDirective PED and CE mark.Benefits of the HYDAC Gas safety block:• zA gas safety block simplifies theoperation of the hydraulic accumulatoron the gas-side and also provides ameans of attaching the above safetyequipment using the various ports.5.8.5 Supports for Hydraulic<strong>Accumulator</strong>s<strong>Accumulator</strong> sets, clamps and consolesfor efficient mounting of hydraulicaccumulators.5.8.5 ACCUSET SBNominal volumes:1 ... 50 lPermitted operating pressure:330 barE 3.000.12/03.128

6. INDUSTRIES andAPPLICATIONSHYDAC <strong>Technology</strong> GmbH isrepresented in almost all industriesof the world which use hydraulicaccumulators.The main sectors are industrialhydraulics, mobile technology andprocess technology.Further applications in oil & gas/offshore as well as more energyefficient systems utilizing accumulatorsare gaining in importance.Listed below is a selection of exampleswith accumulators/dampers which aretypical for these industries:6.1. INDUSTRIAL HYDRAULICSAutomotive Industry• zGeneral industrial hydraulics, e.g. energystorageMachine tools• zSupport for the hydraulics for tool drive ortool change• zEnergy storage in the compact hydraulics ofmachining centresPlastics machinery• z<strong>Accumulator</strong> stations for energy storageduring the injection moulding process• zPulsation damping on the hydraulic driveForming machines• z<strong>Accumulator</strong>s used to store energy tosupport the pumpIron and steel industry• z<strong>Accumulator</strong> to maintain the pressure inrolling mills• zBlast furnace hydraulicsThermal power plants• zEmergency supply for turbine control system• zPulsation damping on pumps• zLubrication, control and seal oil supplyWind turbines• z<strong>Accumulator</strong>s in the pitch control system• zSupport of the pitch drive• z<strong>Accumulator</strong>s on braking unitsMining machinery• zHydraulic accumulators, e.g. in suspendedmonorails• zPulsation damping• zComfort and safety for mobile workingmachinesPaper Industry• zEnergy storage for emergency functions infriction bearing hydraulics• zEnergy storage in high/low pressure powerunitsTest rigs and test systems• zEnergy storage on crash test systems• zPulsation damping on servohydraulic axesE 3.000.12/03.129

6.2. MOBILE TECHNOLOGYAutomotive technology• zAutomatic and manual transmission• zAutomatic clutch systems• zEngine management systems• zPump noise damping• z<strong>Accumulator</strong>s for turbochargeremergency lubricationConstruction Machinery• z<strong>Accumulator</strong>s in braking systems• zChassis damping• zBucket damping• zBoom damping on mobile cranesAgricultural and forestry machines• zFront loader damping• z<strong>Accumulator</strong>s in tractor suspensionsystems• zStone strike protection for ploughs• zBoom suspension on field sprayers6.3. PROCESS TECHNOLOGYChemical industry• zEnergy storage and pulsation damping on dosingpumps• zSuction flow stabilisation on the suction side ofpumpsLoading stations / Refineries• zShock absorption for valve closing• zPulsation damping on pipelinesOffshore / Oil & Gas• z<strong>Accumulator</strong>s to support valve closing systems• zEnergy storage for deep sea rams• zBlow Out Preventers (BOP)• zEmergency function for safety systems• z<strong>Accumulator</strong>s on wellhead control systemsMunicipal machines• zEnergy storage• zBoom damping• zPulsation dampers• zChassis dampingLifting and material handlingtechnology• zNoise-damping• zEnergy recovery• zBraking systemShipping• zWater treatment plants(pump support)• zPulsation damping on diesel engines• zHeave compensation (cranes)• zEmergency function for lifeboats7. WEBSITEPlease visit us at the following address:www.hydac.com.In addition to Industries, Service and Fluid Engineering,under <strong>Product</strong>s » Hydraulic <strong>Accumulator</strong>s, you willfind the standard product range and acomprehensive range of accessories fromHYDAC TECHNOLOGY GmbH.8. Specification formsOur aim is to provide optimum customer service bothbefore and after purchasing the accumulator.The following specification forms are designed tohelp pre-select the required accumulator/damper oraccessories.E 3.000.12/03.1210You can also download these as a pdf document fromthe intranet and internet (www.hydac.com/Hydraulicaccumulators) under the Downloads tab. You can thencomplete them at your convenience on your PC andalso send them to your HYDAC contact, e.g. by E-Mail.

HYDAC <strong>Technology</strong> GmbHIndustriegebietD-66280 Sulzbach/SaarTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.comGeneral ACCUMULATOR Specification Form (Page 1/2)(Subject to technical modifications)Company:Project name:E-Mail:Location:Originator:Tel. no.:Application: Requirement: pieces/yearNote:The appropriate accumulator can be calculated using the HYDAC <strong>Accumulator</strong> Simulation Program ASP.Download from www.hydac.com.Type of accumulator ¨ Bladder accumulator ¨ Piston accumulator ¨ Diaphragm accumulator ¨ __________________Fluids/mediumFluid: Viscosity at 20 °C: cStDensity: kg/m³ Viscosity at operating temperature: cStFunctioning of the pumpAdditional details on the accumulator¨ Continuous operation ¨ Intermittent operation Industry:<strong>Accumulator</strong> dataCountry of installation:Max. operating pressure: bar Design/Certification:Min. operating pressure: bar Specification:Pre-charge pressure at 20 °C (nitrogen): bar Materials*(See catalogue section: No. 3.000, Sizing)<strong>Accumulator</strong> shell:Ambient temperature: °C Fluid connection:Operating temperature: °C Elastomer:Complete cycle time: s Additional informationFluid demand diagram for one pumpand one consumer:Installation dimensions:(height x Ø ext.)Fluid connection: Type:<strong>Accumulator</strong> discharge rate: l/min For thread ¨ internal<strong>Accumulator</strong> discharge time: s ¨ externalFlow rate of the pump: l/min Standard:Pump runs continuously: ¨ Gas connection:Pump starts after discharge:¨Colour/finish:¨ internal¨ externalSpare parts/Accessories:Alternatively:Fluid demand diagram for several pumpsand/or consumers (see Page 2)see www.hydac.comunder <strong>Product</strong>s/<strong>Accumulator</strong>s* dependent on operating temperature and/or fluid resistancemmComments:Date:Name:E 3.000.12/03.1211

HYDAC <strong>Technology</strong> GmbHIndustriegebietD-66280 Sulzbach/SaarTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.comGeneral ACCUMULATOR Specification Form (Page 2/2)(Subject to technical modifications)Fluid demand diagram for several pumps and/or consumersDesignation / ExampleQ v= Consumer flow rate [l/s]E V= Switch-on time of consumer [s]A V= Switch-off time of consumer [s]E P= Switch-on time of pump [s]A P= Switch-off time of pump [s]Q[l/s]E V1 A V1 A V2 A V3E V2 E V3 E V4 A V4consumersQ V1Q V2Q V3Q V4time [s]E P1A P1E P2A P2pumpsPlease indicate cycle data belowNumber of consumers:Number of pumps:Q V1= E V1= A V1= Q P1= E P1= A P1=Q V2= E V2= A V2= Q P2= E P2= A P2=Q V3= E V3= A V3= Q P3= E P3= A P3=Q V4= E V4= A V4= Q P4= E P4= A P4=Q[l/s]time [s]E 3.000.12/03.1212

HYDAC <strong>Technology</strong> GmbHIndustriegebietD-66280 Sulzbach/SaarTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.comShock absorber specification form (Page 1/2)(Subject to technical modifications)Company:Project name:E-Mail:Location:Originator:Tel. no.:Application: Requirement: pieces/yearNote:The appropriate accumulator can be calculated using the HYDAC <strong>Accumulator</strong> Simulation Program ASP.Download from www.hydac.com.Type of accumulator ¨ Bladder accumulator ¨ Piston accumulator ¨ Diaphragm accumulator ¨Cause of the pressure shockComments:<strong>Accumulator</strong> data¨ When pump starts ¨ When pump switches off Max. operating pressure: bar¨ When check valve flap (valve) closes Min. operating pressure: barPre-charge pressure at 20 °C (nitrogen):barFluids/mediaFluid 1) :Density:Pipeline data for a single pipeLength:Diameter (internal):Wall thickness:Material of line:Max. permitted pressure in the line:Total closing time of the valve:Speed of sound in the system:Alternatively:Pipeline data for additional sections of pipe(see Page 2)Pump dataZero head:Pressure of the pump at the operating point:Flow rate of the pump at the operating point:* dependent on operating temperature and/or fluid resistance1)please send datasheetkg/m³mmmmmbarsm/smbarl/min(See catalogue section: No. 3.000, Sizing)Ambient temperature: °COperating temperature: °CFluid connection:Gas connection:Colour/finish:Spare parts/Accessories:Materials*<strong>Accumulator</strong> shell:Fluid connection:Elastomer:Additional information on the accumulator/systemAvailable installation space:(L x W x H)Industry:Country of installation:Design/Certification:Specification:Type:For threadStandard:¨ internal¨ internal¨ external¨ externalsee www.hydac.comunder <strong>Product</strong>s/Hyd. accumulatorsmDate:Name:E 3.000.12/03.1213

Pipeline data for additional sections of pipeDesignation / ExampleH = Zero head of the pump [m]D i= Internal diameter of the pipe [mm]T = Closing time of the valve [s](effectively approx. 30 % of the total closing time)L = Length of the pipeline [m]HYDAC <strong>Technology</strong> GmbHIndustriegebietD-66280 Sulzbach/SaarTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.comShock absorber specification form (Page 2/2)(Subject to technical modifications)HL1L2L3TTankTankD i1 D i2 D i3No. of different pipes: 3L1 = 200 m D i1 = 100 mmL2 = 50 m D i2 = 200 mmL3 = 20 m D i3 = 500 mmTypical values for speed of soundWater = 1200 m/sFuel = 1100 m/sPlease complete below with the pipeline dataNo. of different pipes:L1 = m D i1 = mm L5 = m D i5 = mmL2 = m D i2 = mm L6 = m D i6 = mmL3 = m D i3 = mm L7 = m D i7 = mmL4 = m D i4 = mm L8 = m D i8 = mmE 3.000.12/03.1214

HYDAC <strong>Technology</strong> GmbHIndustriegebietD-66280 Sulzbach/SaarTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.comPULSATION DAMPER Specification Form(Subject to technical modifications)Company:Project name:E-Mail:Location:Originator:Tel. no.:Application: Requirement: pieces/yearNote:The appropriate accumulator can be calculated using the HYDAC <strong>Accumulator</strong> Simulation Program ASP.Download from www.hydac.com.Type of accumulator ¨ Bladder accumulator ¨ Piston accumulator ¨ Diaphragm accumulator ¨Fluids/mediumFluid: Viscosity at 20 °C: cStDensity: kg/m³ Viscosity at operating temperature: cStPump and system dataOper. press./pump pressure:Flow rate:Rpm:No. of displacements:Pump factor:Stroke volume:Comments:¨ singlefor piston pumps: V H=¨ double actingoptional (if available)d 2 x p x H x 1064barl/min1/min1 dm³d = Ø piston:mm Additional informationResult: l gas volume 2) Colour/finish:H = stroke length:mm Installation dimensions:for diaphragm pumps: see manufacturer's specifications(Height x Ø ext.)<strong>Accumulator</strong> dataFluid connection:Pre-charge pressure 1) : barOperating temperature: °CApplication:¨ pressure side ¨ suction sideRequired residual pulsation: % Gas connection:* dependent on operating temperature and/or fluid resistance1)see catalogue section: No. 3.000, Sizing2)normally pre-charged with nitrogen (N 2)Additional details on the accumulatorIndustry:Country of installation:Design/Certification:Specification:Design pressure: barDesign temperature: °CMaterials*<strong>Accumulator</strong> shell:Fluid connection:Elastomer:Spare parts/Accessories:Type:For threadStandard:¨ internal¨ internal¨ externalmm¨ externalsee www.hydac.comunder <strong>Product</strong>s/Hydraulic accumulatorsDate:Name:E 3.000.12/03.1215

Company:Project name:E-Mail:HYDAC <strong>Technology</strong> GmbHIndustriegebietD-66280 Sulzbach/SaarTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.comSILENCER Specification Form(Subject to technical modifications)Location:Originator:Tel. no.:Application: Requirement: pieces/yearSizing example:E00E1E21 Silencer 2 3E44E35E5E66Pump: A10VSO71 Design pressure: 210 bar Silencer inlet: SAE 1 1/4“ 3000 PSIPump rpm: 1500 1/min No. of pump pistons: 9 Silencer outlet: SAE 1 1/4“ 3000 PSIFluid: Aral Vitam GF Fluid density: 890 kg/m³ Design temperature: 50 °CElement no. Length [m] Ø int. [m] Ø ext. [m] Subsequent connection type Hose typeE1 0.5 0.020 0.030 Straight connection –E2 0.4 – 0.200 Straight connection –E3 1.5 0.025 0.040 T-junction 4SP (DIN EN 856)E4 0.6 0.015 0.025 Pressure relief valve –E5 0.2 0.015 0.025 Right-angle –E6 0.6 0.015 0.025 Shut-off valve –Design data:Pump: Design pressure: bar Silencer inlet:Pump rpm: 1/min No. of pump pistons: Silencer outlet:Fluid: Fluid density: Design temperature: °CElement no. Length [m] Ø int. [m] Ø ext. [m] Subsequent connection type Hose typeE1E2E3E4E5E6E7E8E9E10E11E12Comments:E 3.000.12/03.12Date:Name:16

9. SIZING9.1. DEFINITION OF VARIABLES FOR SIZING A HYDRAULIC ACCUMULATORFunction principle <strong>Accumulator</strong> cycle Limits for the gas pre-charge pressureBladder accumulatorp 0≤ 0.9 • p 1with a permitted pressure ratio ofp 2: p 0≤ 4 : 1 Piston accumulator Diaphragm accumulator The accumulator is pre-charged withnitrogen. The separating element(piston, bladder, diaphragm) shuts offthe fluid connection. The minimum operating pressure shouldbe higher than the gas pre-chargepressure. This should prevent theseparating element from striking thefluid connection every time fluid isdischarged. Once the max. operating pressure isreached, the effective volume ΔV isavailable in the accumulator:p 0= Gas pre-charge pressurep 1= Minimum operating pressurep 2= Maximum operating pressureV 0= Effective gas volumeV 1= Gas volume at p 1V 2= Gas volume at p 2t 0= Gas pre-charge temperaturet min= Min. operating temperaturet max= Max. operating temperatureFor HYDAC low pressure accumulators,the following must also be taken intoaccount:Type SB40: p 0 max= 20 barType SB35H: p 0 max= 10 barp 0,tmin≥ 2 bar (piston type 2)p 0,tmin≥ 10 bar (piston type 1)p 0,tmin≤ p 1- 5 barIn extreme cases, during slow charging(isothermal) and rapid discharge (adiabatic)of the effective volume, and after accuratecalculation, the gas pre-charge pressurep 0≥ p 1can be selected.<strong>Accumulator</strong> supplied uncharged orwith 2 bar storage pressure.a) Permitted pressure ratio: p 2: p 0Weld type:The pressure ratio of weld-typediaphragm accumulators is between4 : 1 and 8 : 1, depending on the design,see catalogue sectionDiaphragm <strong>Accumulator</strong>s, No. 3.100,Point 3.1.Screw type:All sizes: 10 : 1Other pressure ratios on requestb) p 0≤ 0.9 • p 19.2. SELECTION OFGAS PRE-CHARGEPRESSUREThe selection of the gas pre-chargepressure defines the accumulator capacity.In order to obtain optimum utilization of theaccumulator volume the following gas prechargepressures are recommended:9.2.1 Recommended valuesfor energy storage:p 0,t max= 0.9 • p 1for shock absorption:p 0,t max= 0.6 to 0.9 • p m(p m= average operating pressure forfree flow)During operation the separating element(piston, bladder, diaphragm) must nottouch the fluid-side connection.Since the volume of the gas increases asthe temperature increases, the gas prechargepressure must be determined at themaximum operating temperature using therecommended values.9.2.2 Limits for gas pre-chargepressure(see right-hand column of table)9.2.3 Temperature effectSo that the recommended gas pre-chargepressures can be maintained, even atrelatively high operating temperatures,the p 0 chargefor charging and testing coldaccumulators must be selected as follows:p 0, t charge= p 0,t max•t charge+ 273t max+ 273t 0= t charge(gas charging temperature in °C)To take the temperature effect into accountwhen sizing accumulators,the pre-charge pressure p 0at min.temperature t 0must be selected as follows:p 0, t min= p 0,t max•t min+ 273t max+ 273for pulsation damping:p 0,t max= 0.6 • p m(p m= average operating pressure)orp 0,t max= 0.8 • p 1(for several operating pressures)E 3.000.12/03.1217

9.3. <strong>Accumulator</strong> sizingon your PCASP - ACCUMULATORSIMULATION PROGRAMExamplePetrol tanker filling stationYou want to size an accumulator foryour hydraulic system and need to findout the required gas volume? How doesthe accumulator actually behave in thesystem?The formulae required for this arecomplicated and also have only limitedrelevance.The solution: HYDAC ASP -<strong>Accumulator</strong> Simulation Program:• z<strong>Accumulator</strong> sizing on your PC withWindows interface for bladder, pistonand diaphragm accumulators andsystems using back-up nitrogen bottles,taking into account isentropic, isothermaland polytropic changes in condition.• zCalculation of accumulator systems withthe possibility of adding accumulators,consumers and pumps with theirparticular switch-on and switch-off times.• zSimulation of pressure, temperature andvolume over the given cycle time. Realgas equations are used for this and theaccumulator type and its heat exchangebehaviour is taken into account in thecalculation.• zSizing of pulsation dampers.• zCalculation of the gas volume and theresidual pulsation of gas-filled pulsationdampers.• zSizing of shock absorbers, calculation ofthe required gas volume for "Joukowskyshock".Complex pipe systems are possible onrequest.• zDisplay of the gas compression and thedegree of efficiency.When loading fuels into vehicles, ships or barrels, the flow is suddenly interrupted whenthe valve closes.This deceleration of mass results in a pressure shock which is also referred to as a“Joukowsky pressure shock”. By using a hydraulic accumulator, the pressure shock canbe reduced to a tolerable level.Given parameters:• zTemperature: 20 °CFluid: PETROL (Premium leaded)(Density: 0.760 kg/dm 3 )• zPipe length from pump to valve:900 m• zPipe Ø internal:Internal diameter = 107.1 mm(DN100 = 114.3 external,wall thickness = 3.6 mm)• zZero head of the pump:147.5 m, equivalent to 11 bar• zPump pressure at operating point: 10 bar (pre-charge pressure p 0= 9 bar)• zMax. permitted pressure of the pipe: 12 bar• zFlow rate:500 l/min• zClosing time of the shut-off valve: 1s (0.33 s effectively)• zPipe material:Steel E = 2.1 x 10 5 N/mm²Required:a. Maximum Joukowsky pressure shock in barb. Maximum flow velocity in the pipe in m/sc. Required accumulator gas volume in litreSolution:a. Maximum Joukowsky pressure shock: 18.867 barb. Maximum flow velocity: 0.925 m/sc. Required accumulator gas volume: 41.795 lE 3.000.12/03.121810. NOTEThe information in this brochure relates tothe operating conditions andapplications described.For applications and operating conditionsnot described here, please contact therelevant technical department.Subject to technical modifications.HYDAC <strong>Technology</strong> GmbHIndustriegebiet66280 Sulzbach/Saar, GermanyTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.com

Bladder <strong>Accumulator</strong>sStandard1. Description1.1. FunctionFluids are practically incompressible andcannot therefore store pressure energy.The compressibility of a gas is utilised inhydraulic accumulators for storing fluids.HYDAC bladder accumulators are basedon this principle, using nitrogen as thecompressible medium.A bladder accumulator consists of afluid section and a gas section with thebladder acting as the gas-proof screen.The fluid around the bladder is connectedto the hydraulic circuit so that thebladder accumulator draws in fluid whenthe pressure increases and the gas iscompressed. When the pressure drops,the compressed gas expands and forcesthe stored fluid into the circuit.HYDAC bladder accumulators can be usedin a wide variety of applications, some ofwhich are listed below:• zenergy storage• zemergency operation• zforce equilibrium• zleakage compensation• zvolume compensation• zshock absorption• zvehicle suspension• zpulsation dampingSee catalogue section:• zHydraulic DampersNo. 3.7011.2. Designshellseal capgas valvelock nutspacerlock nutoil valvevalve protectioncapbladderanti-extrusionringseal ringvent screwDesign• zStandard Bladder <strong>Accumulator</strong>SB330/400/500/550HYDAC standard bladder accumulatorsconsist of the pressure vessel, theflexible bladder with gas valve and thehydraulic connection with check valve.The pressure vessel is seamless andmanufactured from high tensile steel.• zBladder accumulatorSB 330NThe flow optimised design of thestandard oil valve enables the maximumpossible operating fluid flow rate toincrease to 25 l/s on this accumulatortype.• zHigh Flow bladder accumulatorSB330HHYDAC high flow bladder accumulators,type SB330H, are high performanceaccumulators with a flow rate of up to30 l/s. The fluid connection is enlarged toallow higher flow rates.1.3. Bladder materialThe following elastomers are available asstandard:• zNBR (acrylonitrile butadiene rubber,perbunan),• zIIR (butyl rubber),• zFKM (fluoro rubber, Viton ® ),• zECO (ethylene oxide epichlorohydrinrubber).The material must be selected accordingto the particular operating fluid andtemperature.When choosing the elastomer, allowancesmust be made for the fact that the gascan cool down to below the permittedelastomer temperature if there are adversedischarge conditions (high pressure ratiop 2/p 0, high discharging velocity). This cancause cold cracking in the elastomer.The gas temperature can be calculatedusing the HYDAC <strong>Accumulator</strong> SimulationProgram ASP.1.4. CorrosionprotectionFor operation with chemically aggressivemedia, the accumulator shell can besupplied with corrosion protection, such asplastic coating on the inside or chemicalnickel-plating. If this is insufficient, thenstainless steel accumulators must be used.E 3.201.26/03.1219

1.5. Mounting positionHYDAC bladder accumulators can beinstalled vertically, horizontally and at aslant. When installing vertically or at aslant, the oil valve must be at the bottom.On certain applications listed below,particular positions are preferable:• zEnergy storage:vertical,• zPulsation damping:any position from horizontal to vertical,• zMaintaining constant pressure:any position from horizontal to vertical,• zVolume compensation:vertical.If the mounting position is horizontalor at a slant, the effective volume andthe maximum permitted flow rate of theoperating fluid are reduced.1.6. Type of mountingBy using an appropriate adapter, HYDACaccumulators, up to size 1 l, can bemounted directly inline.For strong vibrations and volumes above1 litre, we recommend the use of HYDACaccumulator supports or the HYDACaccumulator mounting set.See catalogue sections:• zSupports for Hydraulic <strong>Accumulator</strong>sNo. 3.502• zACCUSET SBNo. 3.5032. TECHNICALSPECIFICATIONS2.1. EXPLANATORY NOTES2.1.1 Operating pressureSee tables (may differ from nominalpressure for foreign test certificates).2.1.2 Nominal volumeSee tables2.1.3 Effective gas volumeSee tablesBased on nominal dimensions, this differsslightly from the nominal volume and mustbe used when calculating the effectivevolume.2.1.4 Effective volumeVolume of fluid which is available betweenthe operating pressures p 2and p 1.2.1.5 Max. flow rate of operating fluidIn order to achieve the max. flow rategiven in the tables, the accumulator mustbe mounted vertically. It must be noted thata residual fluid volume of approx. 10 % ofthe effective gas volume remains in theaccumulator.2.1.6 FluidsThe following sealing and bladdermaterials are suitable for the fluids listedbelow.Material FluidsNBR20 Mineral oils (HL, HLP,HFA, HFB, HFC), waterECO Mineral oilIIRFKMPhosphate esterChlorinated hydrocarbons,petrol2.1.7 Permitted operating temperatureThe permitted operating temperatures aredependent on the application limits of themetal materials and the bladder.The standard valve bodies, gas valvesand accumulator shells are suitable fortemperatures from -10 °C ... +80 °C.Outside these temperatures, specialmaterial combinations must be used.The following table shows the correlationbetween bladder material and applicationtemperature.Material Temperature rangesNBR20 -15 °C ... + 80 °CNBR21 -50 °C ... + 80 °CNBR22 -30 °C ... + 80 °CECO -30 °C ... +120 °CIIR -40 °C ... +100 °CFKM -10 °C ... +150 °C2.1.8 Gas chargingHydraulic accumulators must only becharged with nitrogen.Never use other gases.RISK OF EXPLOSION!In principle, the accumulator may only becharged with nitrogen class 4.5, filtered to< 3 µm.If other gases are to be used, pleasecontact HYDAC for advice.2.1.9 Limits for gas pre-chargepressurep 0≤ 0.9 • p 1with a permitted pressure ratio of:p 2: p 0≤ 4 : 1p 2= max. operating pressurep 0= gas pre-charge pressure2.1.10 Certificate codesAustralia F1 1)Brazil U3 3)Canada S1 2)ChinaA9CISA6EU member statesUIndia U3 3)JapanPNew ZealandTSwitzerlandUUkraineA10USAS1)Approval required in the individual territories2)Approval required in the individual provinces3)Alternative certificates possibleOn no account must any welding, solderingor mechanical work be carried out on theaccumulator shell. After the hydraulic linehas been connected it must be completelyvented.Work on systems with hydraulicaccumulators (repairs, connectingpressure gauges etc) must only be carriedout once the pressure and the fluid havebeen released.Please read the Operating Manual!No. 3.201.CENote:Application examples, accumulator sizingand extracts from approvals regulations onhydraulic accumulators can be found in thefollowing catalogue section:• z<strong>Accumulator</strong>sNo. 3.0002.1.11 Gas side connectionStandardSeries Volume Gas valve type[l]SB330 / < 1 5/8-18UNFSB400 < 50 7/8-14UNF≥ 50 M50x1.5 / 7/8-14UNFother pressure ranges on request.E 3.201.26/03.1220

2.2. Model code(also order example)SB330 H – 32 A 1 / 112 U – 330 A 050SeriesType codeH = high flowN = increased flow, standard oil valve dimensionsA = shock absorberP = pulsation damperS = suction flow stabiliserB = bladder top-repairableCombinations possible, e.g. HB - High flow with top-repairable bladder orPH - pulsation damper with high flow rate.no details = standardNominal volume [l]Fluid connectionA = standard connection, thread with internal seal faceF = flange connectionC = valve mounting with screws on undersideE = sealing surfaces on front interface (e.g. on thread M50x1.5 - valve)G = male threadS = special connection, to customer specificationGas side1 = standard model (see point 2.1.11)2 = back-up model3 = gas valve 7/8-14UNF with M8 female thread4 = gas valve 7/8-14UNF with gas valve connection 5/8-18UNF5 = gas valve M50x1.5 in accumulators smaller than 50 l6 = 7/8-14UNF gas valve7 = M28x1.5 gas valve8 = M16x1.5 gas valve9 = special gas valve, to customer specificationMaterial code 1)Standard model = 112 for mineral oilsdepending on operating mediumothers on requestFluid connection1 = carbon steel2 = high tensile steel3 = stainless steel 3)6 = low temperature steel<strong>Accumulator</strong> shell0 = plastic coated (internally)1 = carbon steel2 = chemically nickel-plated (internal coating)4 = stainless steel 3)6 = low temperature steel<strong>Accumulator</strong> bladder 2)2 = NBR203 = ECO4 = IIR (butyl)5 = NBR21 (low temperature)6 = FKM7 = Others9 = NBR22Certificate codeU = PED 97/23/ECPermitted operating pressure [bar]ConnectionThread, codes for fluid connections: A, C, E, GA = thread to ISO 228 (BSP)B = thread to DIN 13 or ISO 965/1 (metric)C = thread to ANSI B1.1 (UN..-2B seal SAE J 514)D = thread to ANSI B1.20.1 (NPT)S = special thread, to customer specificationFlange, codes for fluid connection: FA = DIN flangeB = flange ANSI B16.5C = SAE flange 3000 psiD = SAE flange 6000 psiS = special flange, to customer specificationPre-charge pressure p 0[bar] at 20 °C, must be stated clearly, if required!1)Not all combinations are possible2)When ordering spare bladder, please state diameter of the smaller shell port3)Depending on type and pressure ratingE 3.201.26/03.1221

3. DIMENSIONS AND SPARE PARTS3.1. DimensionsNominal volumeValveMax. operating pressure(PED 97/23/EC)Effective gas volumeWeightAmax.B C Ø Dmax.JthreadØ E SW Q 1)Dimensions[l] [bar] [l] [kg] [mm] [mm] [mm] [mm]ISO228 [mm] [mm] [l/s]0.5400 0.5 2.8 27057 33.5 95.5 G 3/4 50 32 43304.5 30211811550 8.5 334 68 121 G 1 45 6330 2.4 10 531 63 118 G 1 1/4 50 102.5550 2.5 539 68 121 G 1 45 6Standard33013.55843.7 419 63 173 G 1 1/4 67 50 104005 550 4.9 23 867 68 121 G 1 45 66 330 5.7 15 531G 1 1/463 17310, 2) 330 9.3 25 728 G 1 1/450 10Standard159.3 31.5 568 103G 2 100 70N 330229255810 H 9 34.5 603 138 G 2 1/2 125 90 301320243250Standard 400 9.3 37.5 572 103 233 G 2 100 70 15500 8.8 45 585 77 68 241Standard1543 686 103G 2 100 70N 330229251258H 46 695 138 G 2 1/2 125 90 30Standard 400 49 666 103 233 G 2 100 70 15Standard1518.4 50.5 896 103G 2 100 70N 3302292558H 17.5 53.5 931 138 G 2 1/2 125 90 30Standard 400 18.4 63.5 896 103 233 100 70G 215500 17 75.5 901 77 68 241 110 75Standard1523.6 69 1062 103 G 2 100 70N 33058 229 25H 24 72 1097 138 G 2 1/2 125 90 30Standard1533.9 87 1411 103G 2 100 70N 3302292558H 32.5 90 1446 138 G 2 1/2 125 90 30Standard 400 33.9 104.5 1411 103 233 100 70G 215500 33.5 127 1446 77 68 241 110 7515117.5 1931 103G 2 100 70N 3302292547.5H 120.5 1966 138 68 G 2 1/2 125 90 30AdaptorforspecialthreadE 3.201.26/03.12Standard 400 142 1931 103 233 G 2 100 70 15500 48.3 169 1951 77 241 756060 182 115680 85 221 1406356100 105 255 1656Standard 330138 68 G 2 1/2 125 90 30130 133 305 1976160 170 396 2006406200 201 485 23061)Q = max. flow rate of operating fluid2)slimline version, for confined spaces22

3.2. Spare PartsSB330/400/440/500/550SB330H / SB330NDesignationItemBladder assemblyconsisting of:Bladder 2Gas valve insert* 3Lock nut 4<strong>Sea</strong>l cap 5Valve protection cap 6O-ring 7<strong>Sea</strong>l kitconsisting of:O-ring 7Washer 15O-ring 16Vent screw 19Support ring 23O-ring 27Repair kit 1)consisting of:Bladder assembly (see above)<strong>Sea</strong>l kit (see above)Anti-extrusion ring 14Oil valve assemblyconsisting of:Valve assembly (items 9-13) 9Anti-extrusion ring 14Washer 15O-ring 16Spacer 17Lock nut 18Vent screw 19Support ring 23* available separately1)When ordering, please state diameter of the smallershell port.Item 1 not available as a spare part.Item 19 for NBR/Carbon steel: seal ring (item 20)is includedItem 25 must be ordered as an accessory (see Point 4).3.3. REPAIR KITSNBR, carbon steelNominal volume: 0.5 ... 200 litresStandard gas valveNom. volume [l] Part no.0.5 021281691 021062612.5 021062004 021062045 021062086 0211210010* 0311751210 0210621213 0210621620 0210622024 0210622432 0210622850 0210625260 0311751380 03117514100 03117515130 03117516160 03117517200 03117558* slimline version for confined spacesothers on requestDetail "X"SB330/400 – 0.5 ... 6 lSB330/400/500 – 10 ... 200 l andSB330H – 10 ... 200 lSB550 – 1 ... 5 lE 3.201.26/03.1223

4. ACCESSORIES FOR BLADDERACCUMULATORS4.1. ADAPTERS (gas side)To monitor the accumulator pre-charge pressure, HYDAC offers aselection of gas side adapters.For standard connection sizes (7/8-14UNF) the adapters shownbelow are available and must be stated separately at time ofordering.For other gas-side accumulator connections (e.g. 5/8-18UNF)please contact your HYDAC agent.4.1.1 Pressure gauge model:Gas side connection on the bladder accumulator for permanentmonitoring of the pre-charge pressure4.1.2 Pressure gauge model with shut-off valveGas side connection on the bladder accumulator for permanentmonitoring of the pre-charge pressure with shut-off option.gauge Ø100Pressure gaugeØ63gauge shut-offvalveapprox.GaugeindicationrangePressuregaugePart no.Adapter body*AdapterassemblyPart no.00366621Part no.– –0 - 10 bar 00614420 021084160 - 60 bar 00606886 030933860 - 100 bar 00606887 00239275 021047780 - 160 bar 00606888 030323480 - 250 bar 00606889 021002170 - 400 bar 00606890 02102117* p max= 400 barGaugeindicationrangePressuregaugePart no.Adapter body*AdapterassemblyPart no.02103381Part no.– –0 - 25 bar 00631380 021052160 - 60 bar 00606771 021100590 - 100 bar 00606772 00363713 031393140 - 160 bar 00606773 032029700 - 250 bar 00606774 031941540 - 400 bar 00606775 02103226* p max= 400 barE 3.201.26/03.1224

4.1.3 Remote monitoring of the pre-charge pressureTo monitor the pre-charge pressure in hydraulic accumulatorsremotely, gas side adapters with pressure gauge and mountingholes are available.In order to connect these adapters directly with the hydraulicaccumulator using appropriate lines, accumulator adapters arealso available for connection at the top (see diagram 1) or forside-connection (see diagram 2).4.2. ADAPTERS FOR STANDARD BLADDERACCUMULATORS (fluid side)To connect the bladder accumulator to pipe fittings. These areavailable separately.O-ring2 holesgauge Ø63approx.GaugeindicationrangePressuregaugePart no.Adapter body*AdapterassemblyPart no.03037666Part no.– –0 - 10 bar 00614420 030958180 - 60 bar 00606886 030958190 - 100 bar 00606887 02116746 030958200 - 160 bar 00606888 030958210 - 250 bar 00606889 030958220 - 400 bar 00606890 03095823* p max= 400 barO-ring 11x2hex.32Diagram 1 Diagram 2D1Accum.conn.*D2 D3 L1 L2 L3 SW O-ringPart no.NBR/(ISO228-BSP) [mm]Carbon[mm] [mm] [mm] [mm] [mm] [mm] steelG 3/4G 3/8 55 12 3228 2817x3 02104346G 1/2 60 14 36 02104348G 3/8 281202116345G 1 1/4G 1/2 34 50 14 46 021052323730x3G 3/4 44 16 02104384G 1 50 67 18 65 02110124G 1/2 341402104853G 2G 3/4 44 60 16 65 021048494448x3G 1 1/4 60 20 02107113G 1 1/2 68 80 22 70 02105905* others on request5. NOTEThe information in this brochure relates to the operatingconditions and applications described.For applications and operating conditions not described, pleasecontact the relevant technical department.Subject to technical modifications.D1ThreadedconnectionD2[mm]ISO228- G 1/4 25ISO228- G 3/8 28T14ISO228- G 1/2 34 16* p max= 400 barAdapter body*Part no.AdapterassemblyPart no.Diag.00238709 02109481 100241740 02102042 200355021 02109483 103280414 00366607 202110594 02110636 100237884 00366608 2HYDAC <strong>Technology</strong> GmbHIndustriegebiet66280 Sulzbach/Saar, GermanyTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.comE 3.201.26/03.1225

E 3.201.26/03.1226

Bladder <strong>Accumulator</strong>sLow Pressure1. Description1.1. FunctionFluids are practically incompressible andcannot therefore store pressure energy.The compressibility of a gas is utilised inhydraulic accumulators for storing fluids.HYDAC bladder accumulators are basedon this principle, using nitrogen as thecompressible medium.A bladder accumulator consists of afluid section and a gas section with thebladder acting as the gas-proof screen.The fluid around the bladder is connectedto the hydraulic circuit so that thebladder accumulator draws in fluid whenthe pressure increases and the gas iscompressed. When the pressure drops,the compressed gas expands and forcesthe stored fluid into the circuit.HYDAC bladder accumulators can be usedin a wide variety of applications, some ofwhich are listed below:• zenergy storage• zemergency operation• zforce equilibrium• zleakage compensation• zvolume compensation• zshock absorption• zvehicle suspension• zpulsation dampingSee catalogue section:• zHydraulic DampersNo. 3.7011.2. DesignHYDAC low pressure bladder accumulatorsconsist of a welded pressure vessel, aflexible bladder with gas valve and ahydraulic connection with check valve or aperforated disc.The table shows the different modelswhich are described in greater detail in thepages that follow:DesignationSB40- 2.5 ... 50Perm.pressure[bar] 2)VolumeQ 1)[l] [l/s]2.5 - 50 740SB40- 70 ... 220 70 - 220 30SB35HB- 20 ... 50 35 20 - 50 20SB16A- 100 ... 450 16SB35A- 100 ... 450 35SB16AH- 100 ... 450 16SB35AH- 100 ... 450 35100 - 4501)Q = max. flow rate of pressure fluid2)Higher pressures on request1.3. Bladder materialThe following elastomers are available asstandard:• zNBR (acrylonitrile butadiene rubber,perbunan),• zIIR (butyl rubber),• zFKM (fluoro rubber, Viton ® ),• zECO (ethylene oxide epichlorohydrin1520rubber).The material must be selected accordingto the particular operating fluid andtemperature.When choosing the elastomer, allowancesmust be made for the fact that the gascan cool down to below the permittedelastomer temperature if there are adversedischarge conditions (high pressure ratiop 2/p 0, high discharging velocity). This cancause cold cracking in the elastomer.The gas temperature can be calculatedusing the HYDAC <strong>Accumulator</strong> SimulationProgram ASP.1.4. CorrosionprotectionFor operation with chemically aggressivemedia, the accumulator shell can besupplied with corrosion protection, such asplastic coating on the inside or chemicalnickel-plating. If this is insufficient, thenstainless steel accumulators must be used.1.5. Mounting positionHYDAC bladder accumulators can beinstalled vertically, horizontally and at aslant. When installing vertically or at aslant, the oil valve must be at the bottom.On certain applications listed below,particular positions are preferable:• zEnergy storage:vertical,• zPulsation damping:any position from horizontal to vertical,• zMaintaining constant pressure:any position from horizontal to vertical,• zPressure surge damping:vertical,• zVolume compensation:vertical.If the mounting position is horizontalor at a slant, the effective volume andthe maximum permitted flow rate of theoperating fluid are reduced.Bladder accumulators SB16A / SB35A andSB16AH / SB35AH must only be installedvertically with the gas side at the top.1.6. Type of mountingFor strong vibrations and volumes above1 litre, we recommend the use of HYDACaccumulator supports or the HYDACaccumulator mounting set.See catalogue sections:• zSupports for Hydraulic <strong>Accumulator</strong>sNo. 3.502• zACCUSET SBNo. 3.503E 3.202.2/03.1227

2. TECHNICALSPECIFICATIONS2.1. EXPLANATORY NOTES2.1.1 Operating pressureSee tables (may differ from nominalpressure for foreign test certificates).2.1.2 Nominal volumeSee tables2.1.3 Effective gas volumeSee tablesBased on nominal dimensions, this differsslightly from the nominal volume and mustbe used when calculating the effectivevolume.2.1.4 Effective volumeVolume of fluid which is available betweenthe operating pressures p 2and p 1.2.1.5 Max. flow rate of the operatingfluidIn order to achieve the max. flow rategiven in the tables, the accumulator mustbe mounted vertically. It must be noted thata residual fluid volume of approx. 10 % ofthe effective gas volume remains in theaccumulator.2.1.6 FluidsThe following sealing and bladdermaterials are suitable for the fluids listedbelow.MaterialNBRECOIIRFKMFluidsMineral oils (HL, HLP, HFA,HFB, HFC), waterMineral oilPhosphate ester, waterChlorinated hydrocarbons,petrol2.1.7 Permitted operating temperatureThe permitted operating temperatures aredependent on the application limits of themetal materials and the bladders.The standard valve bodies, gas valvesand accumulator shells are suitable fortemperatures from -10 °C ... +80 °C.Outside these temperatures, specialmaterial combinations must be used.The following table shows the correlationbetween bladder material and applicationtemperature.Material Temperature rangesNBR20 -15 °C ... +80 °CNBR21 -50 °C ... +80 °CNBR22 -30 °C ... +80 °CECO -30 °C ... +120 °CIIR -40 °C ... +100 °CFKM -10 °C ... +150 °C2.1.8 Gas chargingHydraulic accumulators must only becharged with nitrogen.Never use other gases.RISK OF EXPLOSION!In principle, the accumulator may only becharged with nitrogen class 4.5, filtered to< 3 µm.If other gases are to be used, pleasecontact HYDAC for advice.2.1.9 Limits for gas pre-chargepressurep 0≤ 0.9 • p 1with a permitted pressure ratio of:p 2: p 0≤ 4 : 1p 2= max. operating pressurep 0= gas pre-charge pressureFor HYDAC low pressure accumulators,the following must also be taken intoaccount:Type SB40: p 0 max= 20 barType SB35HB: p 0 max= 10 bar2.1.10 Certificate codesAustralia F1 1)Brazil U3 3)Canada S1 2)ChinaA9CISA6EU member statesUIndia U3 3)JapanPNew ZealandTSwitzerlandUUkraineA10USASothers on request1)Approval required in the individual territories2)Approval required in the individual provinces3)Alternative certificates possibleOn no account must any welding, solderingor mechanical work be carried out on theaccumulator shell. After the hydraulic linehas been connected it must be completelyvented.Work on systems incorporating hydraulicaccumulators (repairs, connectingpressure gauges etc) must only be carriedout once the pressure and the fluid havebeen released.Please read the Operating Manual!No. 3.201.CENote:Application examples, accumulator sizingand extracts from approvals regulations onhydraulic accumulators can be found in thefollowing catalogue section:• z<strong>Accumulator</strong>sNo. 3.000E 3.202.2/03.1228

2.2. Model code(also order example)SB40 A – 100 F 7 / 112 U – 40 ASeriesType codeH = high flowN = increased flow, standard oil valve dimensionsA = shock absorberB = bladder top-repairableCombinations possible, e.g. HB - High flow with top-repairable bladderno details = standardNominal volume [l]Fluid connectionA = standard connection, thread with internal seal faceF = flange connectionC = valve mounting with screws on undersideE = sealing surfaces on front interface (e.g. on thread M50x1.5 - valve)G = male threadS = special connection, to customer specificationGas side1 = standard model2 = back-up model3 = gas valve 7/8-14UNF with M8 female thread4 = gas valve 7/8-14UNF with gas valve connection 5/8-18UNF5 = gas valve M50x1.5 in accumulators smaller than 50 l6 = 7/8-14UNF gas valve7 = M28x1.5 gas valve8 = M16x1.5 gas valve9 = special gas valve, to customer specificationMaterial code 1)Standard model = 112 for mineral oilsdepending on operating mediumOthers on requestFluid connection1 = carbon steel2 = high tensile steel3 = stainless steel 3)6 = low temperature steel<strong>Accumulator</strong> shell0 = plastic coated (internally)1 = carbon steel2 = chemically nickel-plated (internal coating)4 = stainless steel 3)6 = low temperature steel2) 4)<strong>Accumulator</strong> bladder2 = NBR203 = ECO4 = IIR (butyl)5 = NBR21 (low temperature)6 = FKM7 = Others9 = NBR22Certificate codeU = PED 97/23/ECPermitted operating pressure [bar]ConnectionThread, codes for fluid connections: A, C, E, GA = thread to ISO 228 (BSP)B = thread to DIN 13 or ISO 965/1 (metric)C = thread to ANSI B1.1 (UN..-2B seal SAE J 514)D = thread to ANSI B1.20.1 (NPT)S = special thread, to customer specificationFlange, codes for fluid connection: FA = EN 1092-1 welding neck flangeB = flange ASME B16.5C = SAE flange 3000 psiD = SAE flange 6000 psiS = special flange, to customer specificationRequired gas pre-charge pressure must be stated separately!1)Not all combinations are possible2)When ordering spare bladder, please state diameter of the smaller shell port3)Depending on type and pressure rating4)Standard materials, all other materials on requestE 3.202.2/03.1229

3. Low pressure accumulators3.1. Standard bladder accumulatorsSB40-2.5 ... 503.1.1 DesignHYDAC standard low pressure accumulators consist of:• zA welded pressure vessel which can be treated with various types of corrosionprotection for chemically aggressive fluids, or can be supplied in stainless steel.• zA bladder with gas valve. The bladders are available in the elastomers listed underpoint 2.1.• zA hydraulic connector with a perforated disc which is held in place with retaining ring.3.1.3 Spare partsSB40-2.5 ... 503.1.2 DimensionsSB40-2.5 ... 50E 3.202.2/03.12SB40-2.5 ... 50Permitted operating pressure 40 bar(PED 97/23/EC)Nominal Eff. gas Weight Avolume volumeB C Ø D[l] [l] [kg] [mm] [mm] [mm] [mm]2.5 2.5 9 541 122 1085 5.0 13 89110 8.7 14 5336820 18.0 23 843106 21932 33.5 38 1363JthreadISO DIN 13M100x2 G 2K*threadISO 22850 48.6 52 1875 68 2)* Item 16 must be ordered separately1)Q = max. flow rate of operating fluid (at approx. 0.5 bar pressure drop via adapter)2)Lock nutSW[mm]36Q 1)[l/s]7DescriptionItemBladder assembly 1)consisting of:Bladder 2Gas valve insert* 3Lock nut 4<strong>Sea</strong>l cap 5Valve protection cap 6O-ring 7<strong>Sea</strong>l kitconsisting of:O-ring 7Vent screw 13<strong>Sea</strong>l ring 14O-ring 15Repair kit 1)consisting of:Bladder assembly (see above)<strong>Sea</strong>l kit (see above)Hydraulic connector assemblyconsisting of:Perforated disc 10Anti-extrusion ring 11Retaining ring 12Vent screw 13<strong>Sea</strong>l ring 14O-ring 15* available separately1)When ordering, please state diameter of the smallershell port.Item 1 not available as a spare part.30

3.2. Bladder accumulatorsSB40-70 ... 2203.2.1 DesignHYDAC low pressure accumulators, type SB40-70 ... 220 consist of:• zA welded pressure vessel which is compact and yet suitable for high flow rates andlarge volumes.The pressure vessel is manufactured in carbon steel or in stainless steel.• zA bladder with gas valve.• zA hydraulic connector with check valve.3.2.3 Spare partsSB40-70 ... 2203.2.2 DimensionsSB40-70 ... 220SB40-70 ... 220Permitted operating pressure 40 bar(PED 97/23/EC)Nominal Eff. gas Weight Avolume[l]volume[l] [kg]max.[mm]70 64 94 1199100 111 113 1629130 133 133 1879190 192 169 2086220 220 193 23301)Q = max. flow rate of operating fluidB C[mm] [mm]137 78Ø D[mm]356407JthreadISO 228Q 1)[l/s]G 2 1/2 30DescriptionItemBladder assembly 1)consisting of:Bladder 2Gas valve insert* 3Lock nut 4<strong>Sea</strong>l cap 5Valve protection cap 6O-ring 7<strong>Sea</strong>l kitconsisting of:O-ring 7Washer 15O-ring 16Vent screw 19Support ring 23O-ring 27Repair kit 1)consisting of:<strong>Sea</strong>l kit (see above)Bladder assembly (see above)Anti-extrusion ring 14Oil valve assemblyconsisting of:Valve assembly (items 9-13) 9Anti-extrusion ring 14Washer 15O-ring 16Spacer 17Lock nut 18Vent screw 19Support ring 23* available separately1)When ordering, please state diameter of the smallershell port.Item 1 not available as a spare part.Item 19 for NBR/Carbon steel:seal ring (item 20) includedE 3.202.2/03.1231

3.3. Low pressure accumulatorsSB16/35A and SB16/35AH3.3.1 DesignHYDAC low pressure bladder accumulators for large volumes, type SB35A and SB16Aare in a weld construction in carbon steel or stainless steel.The hydraulic outlet is covered by a perforated disc which prevents the flexible bladderextruding from the shell. The bladder is top-repairable.3.3.3 Spare partsSB16/35A, SB16/35AH3.3.2 DimensionsSB16/35A, SB16/35AHDescriptionItemBladder 2Lock nut 3O-ring 11<strong>Sea</strong>l ring 13Vent screw 18O-ring 19Retaining ring 21O-ring 25welding neck flangeDN100 PN16/PN40EN1092-1/11(others on request)welding neck flangeDN80 PN16/PN40EN1092-1/11 (others on request)SB16/35APermitted operating pressure 16/35 bar(PED 97/23/EC)Nominal Eff. Weight ABCDN*volume gas(approx.) (approx.) (approx.)[l]volume[l][kg]SB16A SB35A[mm]SB16A SB35A[mm]SB16A SB35A[mm]SB16A SB35A100 99 84 144 880 880 390 403150 143 101 161 1070 1080 490 503200 187 122 223 1310 1320 685 698300 278 155 288 1710 1720 975 988185 198 100375 392 191 326 2230 2240 1250 1263450 480 237 386 2325 2635 1465 1478E 3.202.2/03.1232SB16/35AHPermitted operating pressure 16/35 bar(PED 97/23/EC)Nominal Eff. Weight ABCDN*volume gas(approx.) (approx.) (approx.)volume [kg][mm][mm][mm][l] [l] SB16AH SB35AH SB16AH SB35AH SB16AH SB35AH SB16AH SB35AH100 99 93 153 957 965 457 465150 143 110 170 1157 1165 557 565200 187 131 230 1417 1425 842 850300 278 164 297 1865 1873 1092 1100245 254 80375 392 200 335 2307 2315 1342 1350450 480 246 395 2702 2710 1542 1550* to EN1092-1/11 / PN16 or PN40others on request

3.4. HIGH FLOW BLADDER ACCUMULATORSB35HB3.4.1 DesignHYDAC high flow bladder accumulators type SB35HB are high performanceaccumulators for flow rates of up to 20 l/s at 2 bar Dp.They consist of a pressure vessel in a weld construction and a flexible bladder with gasvalve.The pressure vessel contains a fixed perforated disc, permitting a high flow rate throughits large free cross-section. For use with chemically aggressive fluids, the shell can bemanufactured in stainless steel. See point 2.1. for bladder materials.3.4.3 Spare partsSB35HB3.4.2 DimensionsSB35HBthebladderistoprepairable.SB35HBPermitted operating pressure 35 bar(PED 97/23/EC)welding neck flangeDN50 / PN40EN1092-1/11(others on request)Nominalvolume[l]Eff. gasvolume[l]Weight[kg]Amax.[mm]C[mm]Ø D[mm]JthreadISO 228SW[mm]20 19.8 43 1081 63 3632 35.0 56 1591219 G 1/250 50.0 69 2091 78 Ø68 2)1)Q = max. flow rate of pressure fluid2)Lock nutQ 1)[l/s]20DescriptionItemBladder assembly 1)consisting of:Bladder 2Gas valve insert* 3Lock nut 4<strong>Sea</strong>l cap 5Valve protection cap 6O-ring 7<strong>Sea</strong>l kitconsisting of:Gas valve insert* 3O-ring 7O-ring 8Repair kit 1)consisting of:Bladder assembly (see above)<strong>Sea</strong>l kit (see above)* available separately1)When ordering, please state diameter of the smallershell port.Item 1 not available as a spare part.4. NOTEThe information in this brochure relates tothe operating conditions andapplications described.For applications and operating conditionsnot described, please contact the relevanttechnical department.Subject to technical modifications.HYDAC <strong>Technology</strong> GmbHIndustriegebiet66280 Sulzbach/Saar, GermanyTel.: +49 (0) 68 97 / 509 - 01Fax: +49 (0) 68 97 / 509 - 464Internet: www.hydac.comE-Mail: speichertechnik@hydac.comE 3.202.2/03.1233

E 3.202.2/03.1234

Bladder <strong>Accumulator</strong>sHigh pressure1. Description1.1. FUNCTIONFluids are practically incompressible andcannot therefore store pressure energy.The compressibility of a gas (nitrogen)is utilised in hydraulic accumulatorsfor storing fluids. HYDAC bladderaccumulators are based on this principle.A bladder accumulator consists of a fluidsection and a gas section with the bladderacting as the gas-proof screen.The fluid around the bladder is connectedto the hydraulic circuit so that thebladder accumulator draws in fluid whenthe pressure increases and the gas iscompressed. When the pressure drops,the compressed gas expands and forcesthe stored fluid into the circuit.HYDAC bladder accumulators can be usedin a wide variety of applications and arealso available in different pressure ranges,see catalogue sections:• zBladder <strong>Accumulator</strong>s StandardNo. 3.201• zBladder <strong>Accumulator</strong>s Low PressureNo. 3.202• z<strong>Accumulator</strong>sNo. 3.0001.2. CONSTRUCTIONThe high pressure bladder accumulatorconsists of the pressure vessel, the flexiblebladder with gas valve and the hydraulicconnection with check valve.1.2.1 Shell materialThe forged pressure vessel is seamlessand manufactured from high tensilechrome molybdenum steel.1.2.2 Bladder materialThe following elastomers are available asstandard:• zNBR (acrylonitrile butadiene rubber,perbunan),• zIIR (butyl rubber),• zFKM (fluoro rubber, Viton ® ),• zECO (ethylene oxide epichlorohydrinrubber).The material used depends on theparticular operating medium andtemperature.When choosing the elastomer, allowancesmust be made for the fact that the gascan cool down to below the permittedelastomer temperature if there are adversedischarge conditions (high pressure ratiop 2/p 0, high discharging velocity). This cancause cold cracking in the elastomer.The gas temperature can be calculatedusing the HYDAC <strong>Accumulator</strong> SimulationProgram ASP.1.2.3 Corrosion protectionFor operation with chemically aggressivemedia, the accumulator shell can bechemically nickel-plated internally orsupplied with a special plastic coating,such as Duroplast.For external corrosion protection theaccumulator can be supplied with anepoxy resin finish specially for offshoreapplications.1.3. MOUNTING POSITIONAND TYPE OFMOUNTINGInformation on secure mounting positionsand mounting elements can be found inthe following catalogue sections:• zBladder <strong>Accumulator</strong>s StandardNo. 3.201• zSupports for Hydraulic <strong>Accumulator</strong>sNo. 3.502• zACCUSET SBNo. 3.503E 3.203.3/03.1235

2. TECHNICAL SPECIFICATIONS2.1. Model code(also order example)SB690 - 32 A 1 / 312 U - 690 DSeriesNominal volume [l]Fluid connectionA = standard connectionGas side connection1 = standard model 2)9 = special model (example: 1/4" - BSP)Material code 1)Fluid connection2 = high tensile steel3 = stainless steel6 = low temperature steel<strong>Accumulator</strong> shell0 = plastic coated (internally)1 = carbon steel2 = chemically nickel-plated (internal coating)6 = low temperature steel8 = plastic coated (e.g. Duroplast) internally and externally<strong>Accumulator</strong> bladder2 = NBR203 = ECO4 = IIR (butyl)5 = NBR21 (low temperature)6 = FKM7 = Others9 = NBR22Certificate codeU = PED 97/23/ECPermitted operating pressure [bar]ConnectionA = Thread to ISO228 (1/2" BSP)D = Thread to ANSI B1.20.3 (1/2" NPTF)Required gas pre-charge pressure must be stated separately!1)Not all combinations are possible2)Gas valve in SB < 10 l = 7/8 - 14 UNF,in SB ≥ 10 l = M50x1.5E 3.203.3/03.122.2. EXPLANATORY NOTES2.2.1 Operating pressure690 bar (10000 psi)Higher pressures on request2.2.2 Permitted working temperature and elastomer resistanceNBR20 -15 °C ... +80 °C waterNBR21 -50 °C ... +80 °C water-glycolNBR22 -30 °C ... +80 °C mineral oilECO -30 °C ... +120 °C mineral oilIIR -40 °C ... +100 °C phosphate ester, waterFKM -10 °C ... +150 °C chlorinated hydrocarbons, petrol2.2.3 Gas chargingHydraulic accumulators must only becharged with nitrogen.Never use other gases.RISK OF EXPLOSION!In principle, the accumulator may only becharged with nitrogen class 4.5, filtered to< 3 µm.If other gases are to be used, pleasecontact HYDAC for advice.36

E 3.203.3/03.1238

Piston <strong>Accumulator</strong>s1. Description1.1. FunctionFluids are practically incompressible andcannot therefore store pressure energy.The compressibility of a gas (nitrogen)is utilised in hydraulic accumulators forstoring fluids. HYDAC piston accumulatorsare based on this principle.A piston accumulator consists of a fluidsection and a gas section with the pistonacting as the gas-proof screen.The gas section is pre-charged withnitrogen.The fluid section is connected to thehydraulic circuit so that the pistonaccumulator draws in fluid when thepressure increases and the gas iscompressed.When the pressure drops, the compressedgas expands and forces the stored fluidinto the circuit.1.2. Designgas valveend cap safety deviceend cappistonsealing systemcylinderexternal sealend cap safety devicefluid connectionHYDAC piston accumulators consist of:• zA cylinder with very finely machinedinternal surface.• zEnd caps on the gas side and the oilside. <strong>Sea</strong>led with O-rings.• zA floating steel or aluminium pistonwhich can easily be accelerated due toits low weight.• zA sealing system adapted to theparticular application.The piston floats on two guide ringswhich prevent metal-to-metal contactbetween the piston and the accumulatorwall.For use with certain aggressive orcorrosive fluids, the parts coming intocontact with the fluid can be nickel platedfor protection, or made entirely fromcorrosion-resistant material.Suitable materials are also available forlow temperature applications.1.3. SEALING SYSTEMSPrecise information about operatingconditions is required in order to selectthe most appropriate sealing system.Important criteria for this selection are, forexample:• zDesign pressure,• zEffective pressure differential,• zSwitching frequency or cycles,• zTemperature fluctuation,• zOperating fluid,• zCleanliness of fluid (micron rating offilter),• zMaintenance requirements.The sealing systems differ according tothe type of piston used, each of which hasits own type and arrangement of seals.The following elastomer sealing materialsare available, depending on the operatingconditions:• zNBR (acrylonitrile butadiene rubber,perbunan),• zFKM (fluoro rubber, Viton ® ),• zPUR (polyurethane).E 3.301.16/03.1239

Piston design type Application Degree of contaminationin the fluid1 • zFor general accumulator operation Optimized for applications withwithout special requirements a high level of contaminationNotesApplication limitations:max. piston velocity: 0.5 m/s2 • zLow-friction design• zFor high piston speeds• zSlow movements without stick-slipeffectApplication limitations:max. piston velocity: 3.5 m/s3 • zLow-friction design• zSimple-to-fit seals• zSlow movements without stick-slipeffectApplication limitations:max. piston velocity: 0.8 m/s4 • zLow-friction design with emergencysafety features• zSlow movements without stick-slipeffect• zVery low oil transfer to the gas sideFiltration:NAS 1638 - Class 6ISO 4406 - Class 17/15/121 guide ring forpistons with Ø ≤ 150 mm2 guide rings forpistons Ø ≥ 180 mmApplication limitations:max. piston velocity: 5 m/sE 3.301.16/03.1240

1.4. Mounting positionHYDAC piston accumulators operate inany position.Vertical installation is preferable withthe gas-side at the top, to preventcontamination from the fluid settling onthe piston seals. For accumulators withcertain piston position indicators verticalinstallation is essential (see 1.7.). Pistonaccumulators with a piston diameter≥ 355 mm must only be mounted vertically.1.5. ADVANTAGES OFHYDAC PISTONACCUMULATORS• zcomplete range from 0.1 ... 1200 Inominal volume,• zhigh ratios possible between pre-chargepressure and max. working pressure,• zeconomic solution using back-up gasbottles for low pressure differentials,• zhigh flow rates possible;limitation: max. piston velocity,• zpower savings,• zhigh level of efficiency of the hydraulicinstallation,• zgas-tight and leakage free,• zno sudden discharge when seals areworn,• zrequires little space,• zmonitoring of the volume across theentire piston stroke or electrical limitswitch.Further advantages of using thelow-friction sealing system:• zminimum friction,• zalso suitable for low pressuredifferentials,• zno start-up friction,• zno stick-slip,• zlow noise, no vibration,• zhigh piston velocityup to 5 m/s for piston type 4,• zimproved accumulator efficiency,• zgood life expectancy of sealsbecause of low wear,• zsuitable for large temperaturefluctuations,• zlow maintenance requirement.1.6. TECHNICALREQUIREMENTSHYDAC piston accumulators are suitablefor high flow rates. With the largest pistonaccumulator diameter made to date of800 mm, a flow rate of 1000 l/s can beachieved at a piston velocity of 2 m/s.1.6.1 Effect of sealing frictionThe permitted piston velocity depends onthe sealing friction.Higher piston velocities are possible wherethere is less sealing friction.HYDAC piston accumulators of pistondesign type 2 allow velocities of up to3.5 m/s.1.6.2 Permitted velocitiesGas velocityThe flow velocities in the gas connectionand pipe system should be limited to30 m/s when using piston accumulators ofthe back-up type. Gas velocities of over50 m/s should be avoided at all costs.Oil velocityIn order to limit the pressure losses whenthe operating fluid is displaced, the flowvelocity should not exceed 10 m/s in theadapter cross-section.1.6.3 Function tests and fatigue testsFunction tests and fatigue tests arecarried out to ensure the developmentand continuous improvement of our pistonaccumulators.By subjecting the accumulators toendurance tests under realistic as wellas extreme working conditions, importantdata can be obtained about the longtermbehaviour of the components. In thecase of piston accumulators, importantinformation on gas density and the lifeexpectancy of seals is gained from suchtests.Vital data for use in accumulator sizing isgained by altering the working pressureand switching cycles.1.6.4 FluidsThe following sealing materials are suitablefor the fluids listed below:NBR, resistant to:• zmineral oils (HL and HLP)• zfire-resistant fluids from the groups HFA,HFB and HFC• zwater and seawaterup to approx. 100 °CNBR, not resistant to:• zaromatic hydrocarbons• zchlorinated hydrocarbons• zamines and ketones• zhydraulic fluids of type HFDFPM, resistant to:• zmineral oils (HL and HLP)• zhydraulic fluids of type HFD• zfuels as well as aromatic and chlorinatedhydrocarbons• zinorganic acids (but not all, pleasecontact our technical department)FPM, not resistant to:• zketones and amines• z(anhydrous) ammonia• zorganic acids such asformic acid and acetic acidPUR, resistant to:• zmineral oils (HL and HLP)• znon-flam fluids from the HFA groupPUR, not resistant to:• zwater and water-glycol mixtures• zalkalis• zacids1.6.5 Temperature ranges of the sealsMaterial HYDAC Temp. rangeabbrev. code long-termNBR 2 -20 °C ... + 80 °CFPM 6 -15 °C ... +160 °CPUR 8 -30 °C ... + 80 °CFor temperatures outside these ranges,please contact our technical departmentfor more information. There are alsospecial grades available depending on theapplication.1.6.6 Gas chargingHydraulic accumulators must only becharged with nitrogen.Never use other gases.RISK OF EXPLOSION!In principle accumulators may only becharged with nitrogen class 4.5, filtered to< 3 µm.If other gases are to be used, pleasecontact HYDAC for advice.E 3.301.16/03.1241