Manual thermoMETER CS - Micro-Epsilon

Manual thermoMETER CS - Micro-Epsilon

Manual thermoMETER CS - Micro-Epsilon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

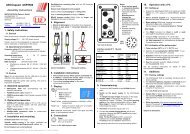

Description1.3 CautionsAvoid abrupt changes of the ambient temperature.In case of problems or questions which may arise when you use the <strong>CS</strong>, please contact our service department.Read the instruction manual carefully before the initial start-up. The producer reserves the right to change theherein described specifications in case of technical advance of the product.1.4 Factory Default SettingsThe unit has the following presetting at time of delivery:Emissivity 0.950Transmission 1.000Average timeSmart averaging0.3 sactiveSmart averaging hysteresis 2 °CAmbient temperature sourceStatus-LED functionInput (IN/ OUT/ green)Output (OUT/ yellow)internal (sensor)Self diagnosticCommunication inputmV outputTemperature range 0 ... 350 °COutput voltageVcc adjustSignal processing0 ... 3.5 VinactiveHold mode: offCalibration Gain 1.000/ Offset 0.0Failsafeinactive<strong>thermoMETER</strong> <strong>CS</strong>Page 6

Technical Data2. Technical Data2.1 General SpecificationsEnvironmental rating IP 63Ambient temperature -20 ... 80 °<strong>CS</strong>torage temperature -40 ... 85°CRelative humidity 10 ... 95 °C, non condensingMaterialStainless steelDimensionsM12x1, 85 mm longWeight58 gCable length1 m (standard), 3 m, 8 m, 15 mKabeldurchmesser 4,3 mmVibrationIEC 68-2-6: 3 G, 11 - 200 Hz, any axisShockIEC 68-2-27: 50 G, 11 ms, any axis<strong>thermoMETER</strong> <strong>CS</strong>Page 9

Technical Data2.3 Measurement SpecificationsTemperature rangeSpectral range 8 ... 14 µmOptical resolution 15:1CF-lens (optional)Accuracy 1)Repeatability 1)Temperature coefficient 2)Temperature resolution(NETD) 3)Response timeWarm-up timeEmissivity/ GainTransmissivityInterface (optional)Signal processingSoftware-40 ... 400 °C (scalable via software); (optional up to 1030 °C)0.8 mm@ 10 mm± 1.5 °C or ± 1.5 % of reading (whichever is greater)± 0.75 °C or ± 0.75 % of reading (whichever is greater)± 0.05 K/ K or ± 0.05 %/ K (whichever is greater)0.1 K25 ms (95 % signal/ adjustable up to 999 s via software)10 min0.100 ... 1.100 (adjustable via 0 - 5 VDC input or software)0.100 ... 1.000 (adjustable via software)USB programming interfaceAverage, Peak hold, Valley hold, Advanced peak hold with threshold andhysteresis, Triggered signal output, Triggered peak hold function (adjustablevia software)optional1) at ambient temperature 23 ± 5 °C and object temperatures > 0 °C2) for ambient temperatures < 18 °C and > 28 °C3) at time constant ≥ 100 ms with smart averaging and an object temperature of 25 °C<strong>thermoMETER</strong> <strong>CS</strong>Page 12

Technical Data2.4 Optical ChartsThe following optical charts show the diameter of the measuring spot in dependence on the distancebetween measuring object and sensor. The spot size refers to 90 % of the radiation energy. The distance isalways measured from the front edge of the sensor housing/ CF-lens holder/ air purge.Abb. 1: Optical chart (15:1)iThe size of the measuring object and the optical resolution of the infrared thermometer determine themaximum distance between sensor and measuring object. In order to prevent measuring errors theobject should fill out the field of view of the optics completely. Consequently, the spot should at all timeshave at least the same size like the object or should be smaller than that.Abb. 2: Optical chart (15:1) with CF-lens (0.8 mm@ 10 mm)<strong>thermoMETER</strong> <strong>CS</strong>Page 13

Technical Data2.5 Close Focus OpticsThe optional CF-lens allows the measurement of small objects. The CF optics can also be combined with alaminar air purge:iAbb. 3: CF-lens [TM-CF-<strong>CS</strong>]Abb. 4: Laminar air purge with integratedCF-lens [TM-APLCF-<strong>CS</strong>]If the CF-lens is used, the transmission has to be set to 0.78. To change this value the optional USB-Kit(including software) is necessary.<strong>thermoMETER</strong> <strong>CS</strong>Page 14

LED Functions3. LED FunctionsThe green LED can be programmed for the following functions. For the programming the USB adapter cableincl. software (option) is necessary. The factory default setting for the LED is self diagnostic.LED AlarmAutomatic aiming supportSelf diagnosticTemperature Code indicationOff3.1 Automatic Aiming SupportLED lights up if the object temperature exceeds or deceeds an alarmthreshold.Sighting feature for an accurate aiming of the <strong>CS</strong> to hot or cold objectsLED is indicating different states of the sensor.Indication of the object temperature via the LEDLED deactivatedThe automatic aiming support helps to adjust the unit to an object which has a temperature different to thebackground. If this function is activated via software the sensor is looking for the highest object temperature;means the threshold value for activating the LED will be automatically tuned.This works also if the sensor is aimed at a new object (with probably colder temperature). After expiration of acertain reset time (default setting: 10 s) the sensor will adjust the threshold level for activation of the LED new.<strong>thermoMETER</strong> <strong>CS</strong>Page 15

LED Functions3.2 Self DiagnosticWith this function the current status of the sensor will be indicated by different flash modes of the LED.iIf activated, the LED will show one of five possible states of the sensor:StatusLED modeNormal intermittent off - - - - -Sensor overheated fast flash - - - - - - - - - -Out of measuring range double flash -- -- -- -- -- --Not stableAlarm faultintermittent onalways onAt a supply voltage (Vcc) ≥ 12 V it takes about 5 minutes until the sensor works in a stable mode.Therefore, after switching on the unit, the LED will show a not stable state for up to 5 minutes.Sensor overheated:Out of meas. range:Not stable:Alarm fault:The internal temperature probes have detected an invalid high internaltemperature of the <strong>CS</strong>.The object temperature is out of measuring range.The internal temperature probes have detected an unequally internal temperatureof the <strong>CS</strong>.Current through the switching transistor of the open-collector output is too high.<strong>thermoMETER</strong> <strong>CS</strong>Page 16

LED Functions3.3 Temperature Code IndicationWith this function the current measured object temperature will be indicated as percentage value by long andshort flashing of the LED.At a range setting of 0 - 100 °C 0 - 100 % the LED flashing indicates the temperature in °C.Long flashing first digit: xxShort flashing second digit: xx10-times long flashing first digit = 0: 0x10-times short flashing second digit = 0: x0Examples:87 °C 8-times long flashingindicatesand afterwards7-times short flashingindicates31 °C 3-times long flashingindicatesand afterwards1-times short flashingindicates8 °C 10-times long flashingindicatesand afterwards8-times short flashingindicates20 °C 2-times long flashingindicatesand afterwards10-times short flashingindicates8787313108082020<strong>thermoMETER</strong> <strong>CS</strong>Page 17

Installation4. Installation4.1 Mechanical InstallationThe <strong>CS</strong> is equipped with a metric M12x1 thread and can be installed either directly via the sensor thread orwith the help of the both hex nuts (standard) to the mounting bracket available.For an exact aiming of the sensor to an object the LED function Automatic Aiming Support, see Chap. 3.1,can be used.<strong>thermoMETER</strong> <strong>CS</strong>Page 18

Installation4.2 Mounting AccessoriesAbb. 5: Mounting bracket, adjustablein one axis [TM-FB-<strong>CS</strong>]Abb. 6: Mounting bolt with M12x1thread, adjustable in one axis [TM-MB-<strong>CS</strong>]Abb. 7: Mounting fork with M12x1thread, adjustable in two axes [TM-MG-<strong>CS</strong>]Abb. 8: Mounting bracket, adjustablein one axis [TM-AB-<strong>CS</strong>]iThe Mounting fork can be combined with the mounting bracket [TM-FB-<strong>CS</strong>] using the M12x1 thread.<strong>thermoMETER</strong> <strong>CS</strong>Page 19

Installation4.3 Air Purge CollarsThe lens must be kept clean at all times from dust, smoke, fumes and other contaminants in order to avoidreading errors. These effects can be reduced by using an air purge collar. Make sure to use oil-free, technicallyclean air, only.Abb. 9: Standard air purgecollar; fits to the mountingbracket; hose connection:3x5 mm [TM-AP-<strong>CS</strong>]iAbb. 10: Laminar air purge collar - theside air outlet prevents a cooling downof the object in short distances; hoseconnection: 3x5 mm [TM-APL-<strong>CS</strong>]A combination of the Laminar airpurge collar with the bottom sectionof the Mounting fork allows anadjustment in two axes.[TM-APL-<strong>CS</strong> + TM-MG-<strong>CS</strong>]The needed amount of air (ca. 2 ... 10 l/ min.) depends on the application and the installation conditionson-site.<strong>thermoMETER</strong> <strong>CS</strong>Page 20

Installation4.4 Further AccessoriesAbb. 11: Right angle mirror,enables measurement with90 °angle [TM-RAM-<strong>CS</strong>]iAbb. 12: Protective window,same mechanical size as CFlens [TM-PW-<strong>CS</strong>]Abb. 13: USB-Kit: USB adapter cableinclusive terminal block and software CD[TM-USBK-<strong>CS</strong>]If the protective window is used, the transmission has to be set to 0.83. To change this value the optionalUSB-Kit (including CompactConnect software) is necessary.All accessories can be ordered using the according part numbers in brackets [ ].<strong>thermoMETER</strong> <strong>CS</strong>Page 21

Installation4.5 Electrical Installation4.5.1 Analog Device (mV Output on OUT Pin)The output impedance must be ≥ 10 kΩ.4.5.2 Analog Device (Thermocouple Type K Output on OUT t/c K Pins / only at Model <strong>CS</strong>TK-SF15)The output impedance must be ≥ 20 kΩ.On the model <strong>CS</strong>TK-SF15 you can choose between a mV output (0 - 5 or 0 - 10 V; scalable via software) anda thermocouple output type K.The factory default setting is 0 - 3.5 V (according to 0 - 350 °C); the thermocouple output is inactive, seeChap. 1.4.<strong>thermoMETER</strong> <strong>CS</strong>Page 22

InstallationTo activate the thermocouple output the USB adapter cable and the software is needed. This output suppliesa voltage according to the characteristic curve type K.If you want to extend this output you have to use a suitable thermocouple extension cable (NiCr-Ni).iThe shield [black] on the <strong>CS</strong> is not connected to GND [brown].In any case it is necessary to connect the shield to ground or GND (whichever works best)!4.5.3 Digital CommunicationFor a digital communication the optional USB programming kit isrequired. Please connect each wire of the USB adapter cable with thesame colored wire of the sensor cable by using the terminal block.Press with a screw driver as shown in the picture to loose a contact.The sensor is offering two ways of digital communication:--bidirectional communication (sending and receiving data)--unidirectional communication (burst mode - the sensor is sending data only)<strong>thermoMETER</strong> <strong>CS</strong>Page 23

Installation4.5.4 Open Collector OutputThe open collector output is an additional alarm output on the <strong>CS</strong> and can control an external relay e.g.In addition the analog output can be used simultaneously.4.5.5 Direct Connection to an RS232 Interface on the ComputerThe <strong>CS</strong> works with a UART voltage of 3.3 V. For a bidirectional RS232 connection of the sensor the followinginterface circuits can be used: MAX3380 or MAX3321 (manufacturer: Maxim).<strong>thermoMETER</strong> <strong>CS</strong>Page 24

Schematic Circuit Diagrams for Maintenance Applications5. Schematic Circuit Diagrams for Maintenance ApplicationsAbb. 14: Open collector output fordirect 24 VDC signal lamp controlAbb. 15: Common power supply voltage change to adjust simultaneouslyalarm levels and emissivity values [Vcc adjust mode]<strong>thermoMETER</strong> <strong>CS</strong>Page 25

Schematic Circuit Diagrams for Maintenance ApplicationsAbb. 16: Simple common alarm and pre-alarm generation<strong>thermoMETER</strong> <strong>CS</strong>Page 26

Software6. Software6.1 InstallationInsert the installation CD into the according drive on your computer. If the autorun option is activated theinstallation wizard will start automatically.Otherwise please start setup.exe from the CR-ROM. Follow the instructions of the wizard until the installationis finished.The installation wizard will place a launch icon on the desktop and in the start menu. If you want to uninstallthe software from your system please use the uninstall icon in the start menu.iYou will find a detailed software manual on the CD.6.2 Minimum System Requirements--Windows XP, Vista, 7--USB interface--Hard disc with at least 30 MByte free space--At least 128 MByte RAM--CD-ROM drive<strong>thermoMETER</strong> <strong>CS</strong>Page 27

Software6.3 Main Features--Graphic display for temperature trends and automaticdata logging for analysis and documentation--Complete sensor setup and remote controlling--Adjustment of signal processing functions--Programming of outputs and functional inputs6.4 Communication SettingsSerial InterfaceBaud rate:Data bits: 8Parity:Stop bits: 1Flow control:Protocol9600 baudnoneoffAll sensors of the <strong>CS</strong> series are using a binary protocol. To get a fast communication the protocol has no additionaloverhead with CR, LR or ACK bytes.To power the sensor the control signal „DTR“ has to be set.<strong>thermoMETER</strong> <strong>CS</strong>Page 28

Digital Command Set7. Digital Command SetCommand list <strong>CS</strong>/ <strong>CS</strong>micro/ CXDecimal HEX Binary /ASCIICommand Data Reply Result Unit1 0x01 Binary READ Temp - Target no byte 1 byte 2 = (byte1 x 256 + byte2 - 1000) / 10 °C2 0x02 Binary READ Temp - Head no byte 1 byte 2 = (byte1 x 256 + byte2 - 1000) / 10 °C3 0x03 Binary READ current Temp - Target no byte 1 byte 2 = (byte1 x 256 + byte2 - 1000) / 10 °C4 0x04 Binary READ Emissivity no byte 1 byte 2 = (byte1 x 256 + byte2) / 10005 0x05 Binary READ Transmission no byte 1 byte 2 = (byte1 x 256 + byte2) / 10009 0x09 Binary READ Processor Temperature no byte 1 = (byte1 x 256 + byte2 - 1000) / 1014 0x0E Binary READ Serial number no byte 1 byte 2byte 3= byte1 x 65536 + byte2 x 256 + byte 315 0x0F Binary READ FW Rev. no byte 1 byte 2 = byte1 x 256 + byte2129 0x081 Binary SET DAC mV/ mA byte 1 byte 1 byte1 = mV (mA) x 10(e.g. 4 mA = 4 x 10 = 40)130 0x082 Binary RESET of DAC mV/ mAoutput132 0x084 Binary SET Emissivity byte 1 byte 2 byte 1 byte 2 = (byte1 x 256 + byte2) / 1000°CBurstmode (unidirectional)After switch on a continuous serial signal will be created. The burst string can be configured with CompactConnect software.Burst string Example Complete Burst string Conversion to decimal value2 synchronisation bytes: AAAA ------ ------2 bytes for each output value (hi lo) 03B8 AAAA 03B8 Process temp. [°C] = (HEX Dec(03B8)-1000)/10 = -4.8<strong>thermoMETER</strong> <strong>CS</strong>Page 29

Digital Command SetTemperature calculation at <strong>CS</strong>micro hs: (byte1 x 256 + byte2 - 10000) / 100Examples (all bytes in HEX):Readout of object temperatureSend 01 Command for readout of object temperatureReceive 04 D3 Object temperature in tenth degree + 1000 04 D3 = dec. 12351235 - 1000 = 235235 / 10 = 23.5 ° CReadout of object temperature (at <strong>CS</strong>micro 2Whs)Send 01 Command for readout of object temperatureReceive 30 3E Object temperature in hundredth degree + 10000Set of emissivitySend 84 03 B6 03B6 = dec. 950Receive 03 B6 950 / 1000 = 0.950<strong>thermoMETER</strong> <strong>CS</strong>Page 30

Basics of Infrared Thermometry8. Basics of Infrared ThermometryDepending on the temperature each object emits a certain amount of infrared radiation. A change in thetemperature of the object is accompanied by a change in the intensity of the radiation. For the measurementof „thermal radiation“ infrared thermometry uses a wave-length ranging between 1 µ and 20 µm.The intensity of the emitted radiation depends on the material. This material contingent constant is describedwith the help of the emissivity which is a known value for most materials (see enclosed table emissivity).Infrared thermometers are optoelectronic sensors. They calculate the surface temperature on the basis of theemitted infrared radiation from an object. The most important feature of infrared thermometers is that they enablethe user to measure objects contactless. Consequently, these products help to measure the temperatureof inaccessible or moving objects without difficulties. Infrared thermometers basically consist of the followingcomponents:--Lens--Spectral filter--Detector--Electronics (amplifier/ linearization/ signal processing)The specifications of the lens decisively determine the optical path of the infrared thermometer, which is characterizedby the ratio Distance to Spot size.The spectral filter selects the wavelength range, which is relevant for the temperature measurement. Thedetector in cooperation with the processing electronics transforms the emitted infrared radiation into electricalsignals.<strong>thermoMETER</strong> <strong>CS</strong>Page 31

Emissivity9. Emissivity9.1 DefinitionThe intensity of infrared radiation, which is emitted by each body, depends on the temperature as well as onthe radiation features of the surface material of the measuring object. The emissivity (e - <strong>Epsilon</strong>) is used asa material constant factor to describe the ability of the body to emit infrared energy. It can range between 0and 100 %. A “blackbody“ is the ideal radiation source with an emissivity of 1.0 whereas a mirror shows anemissivity of 0.1.If the emissivity chosen is too high, the infrared thermometer may display a temperature value which is muchlower than the real temperature - assuming the measuring object is warmer than its surroundings. A lowemissivity (reflective surfaces) carries the risk of inaccurate measuring results by interfering infrared radiationemitted by background objects (flames, heating systems, chamottes). To minimize measuring errors in suchcases, the handling should be performed very carefully and the unit should be protected against reflectingradiation sources.9.2 Determination of Unknown Emissivities--First, determine the actual temperature of the measuring object with a thermocouple or contact sensor.Second, measure the temperature with the infrared thermometer and modify the emissivity until the displayedresult corresponds to the actual temperature.--If you monitor temperatures of up to 380 °C you may place a special plastic sticker (emissivity dots - partnumber: TM-ED-LS) onto the measuring object, which covers it completely. Now set the emissivity to 0.95and take the temperature of the sticker. Afterwards, determine the temperature of the adjacent area on themeasuring object and adjust the emissivity according to the value of the temperature of the sticker.--Cove a part of the surface of the measuring object with a black, flat paint with an emissivity of 0.98. Adjustthe emissivity of your infrared thermometer to 0.98 and take the temperature of the colored surface. Afterwards,determine the temperature of a directly adjacent area and modify the emissivity until the measuredvalue corresponds to the temperature of the colored surface.<strong>thermoMETER</strong> <strong>CS</strong>Page 32

CE-Conformity9.3 Characteristic EmissivitiesIn case none of the methods mentioned above help to determine the emissivity you may use the emissivitytables, see Chap. 12., see Chap. 13. These are average values, only. The actual emissivity of materialdepends on the following factors:--Temperature--Measuring angle--Geometry of the surface--Thickness of the material--Constitution of the surface (polished, oxidized, rough, sandblast)--Spectral range of the measurement--Transmissivity (e.g. with thin films)10. CE-ConformityThe product complies with the following standards:EMC: EN 61326-1 : 2006EN 61326-2-3 : 2006Safety regulations: EN 61010-1 : 2001The product accomplishes the requirements of the EMC Directive 2004/108/EC.Read the instruction manual carefully before the initial start-up. The producer reserves the right to change theherein described specification in case of technical advance of the product.<strong>thermoMETER</strong> <strong>CS</strong>Page 33

Warranty11. WarrantyAll components of the device have been checked and tested for perfect function in the factory. In the unlikelyevent that errors should occur despite our thorough quality control, this should be reported immediately toMICRO-EPSILON. The warranty period lasts 12 months following the day of shipment. Defective parts, exceptwear parts, will be repaired or replaced free of charge within this period if you return the device free of cost toMICRO-EPSILON.This warranty does not apply to damage resulting from abuse of the equipment and devices, from forcefulhandling or installation of the devices or from repair or modifications performed by third parties. No otherclaims, except as warranted, are accepted. The terms of the purchasing contract apply in full.MICRO-EPSILON will specifically not be responsible for eventual consequential damages.MICRO-EPSILON always strives to supply the customers with the finest and most advanced equipment. Developmentand refinement is therefore performed continuously and the right to design changes without priornotice is accordingly reserved.For translations in other languages, the data and statements in the German language operation manual areto be taken as authoritative.<strong>thermoMETER</strong> <strong>CS</strong>Page 34

Appendix A - Emissivity Table Metals12. Appendix A - Emissivity Table MetalsMaterialtypical EmissivityMaterialtypical EmissivityAluminium non oxidized 0.02 - 0.1polished 0.02 - 0.1roughened 0.1 - 0.3oxidized 0.2 - 0.4Brass polished 0.01 - 0.05roughened 0.3oxidized 0.5Copper polished 0.03roughened 0.05 - 0.1oxidized 0.4 - 0.8Chrome 0.02 - 0.2Gold 0.01 - 0.1Haynes alloy 0.3 - 0.8Inconel electro polished 0.15sandblast 0.3 - 0.6oxidized 0.7 - 0.95Iron non oxidized 0.05 - 0.2rusted 0.5 - 0.7oxidized 0.5 - 0.9forged, blunt 0.9Iron, casted non oxidized 0.2oxidized 0.6 - 0.95Lead polished 0.05 - 0.1roughened 0.4oxidized 0.2 - 0.6Magnesium 0.02 - 0.1Mercury 0.05 - 0.15Molybdenum non oxidized 0.1oxidized 0.2 - 0.6Monel (Ni-Cu) 0.1 - 0.14Nickel electrolytic 0.05 - 0.15oxidized 0.2 - 0.5Platinum black 0.9Silver 0.02Steel polished plate 0.1rustless 0.1 - 0.8heavy plate 0.4 - 0.6cold-rolled 0.7 - 0.9oxidized 0.7 - 0.9Tin non oxidized 0.05Titanium polished 0.05 - 0.2oxidized 0.05 - 0.6Wolfram polished 0.03 - 0.1Zinc polished 0.02oxidized 0.1<strong>thermoMETER</strong> <strong>CS</strong>Page 35

Appendix B - Emissivity Table Non Metals<strong>thermoMETER</strong> <strong>CS</strong>13. Appendix B - Emissivity Table Non MetalsMaterialtypical EmissivityAsbestos 0.95Asphalt 0.95Basalt 0.7Carbon non oxidized 0.8 - 0.9graphite 0.7 - 0.8Carborundum 0.9Ceramic 0.95Concrete 0.95Glass 0.85Grit 0.95Gypsum 0.8 - 0.95Ice 0.98Limestone 0.98Paint non alkaline 0.9 - 0.95Paper any color 0.95Plastic > 50 µm non transparent 0.95Rubber 0.95Sand 0.9Snow 0.9Soil 0.9 - 0.98Textiles 0.95Water 0.93Wood natural 0.9 - 0.95Page 36

Appendix C - Smart Averaging14. Appendix C - Smart AveragingThe average function is generally used to smoothen the output signal. With the adjustable parameter timethis function can be optimal adjusted to the respective application. One disadvantage of the average functionis that fast temperature peaks which are caused by dynamic events are subjected to the same averagingtime. Therefore those peaks can only be seen with a delay on the signal output.The function Smart Averaging eliminates this disadvantage by passing those fast events without averagingdirectly through to the signal output.Abb. 17: Signal graph with Smart Averaging functionAbb. 18: Signal graph without Smart Averagingfunction<strong>thermoMETER</strong> <strong>CS</strong>Page 37

MICRO-EPSILON MESSTECHNIK GmbH & Co. KGKönigbacher Str. 15 · 94496 Ortenburg / GermanyTel. +49 (0) 8542 / 168-0 · Fax +49 (0) 8542 / 168-90info@micro-epsilon.de · www.micro-epsilon.comX9751203-B021013HDRMICRO-EPSILON MESSTECHNIK*X9751203-B03*